Gluing cable connector box

A joint box and cable technology, applied in the direction of cable joints, cable terminals, etc., to achieve the effect of advanced structural design and convenient fixing of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

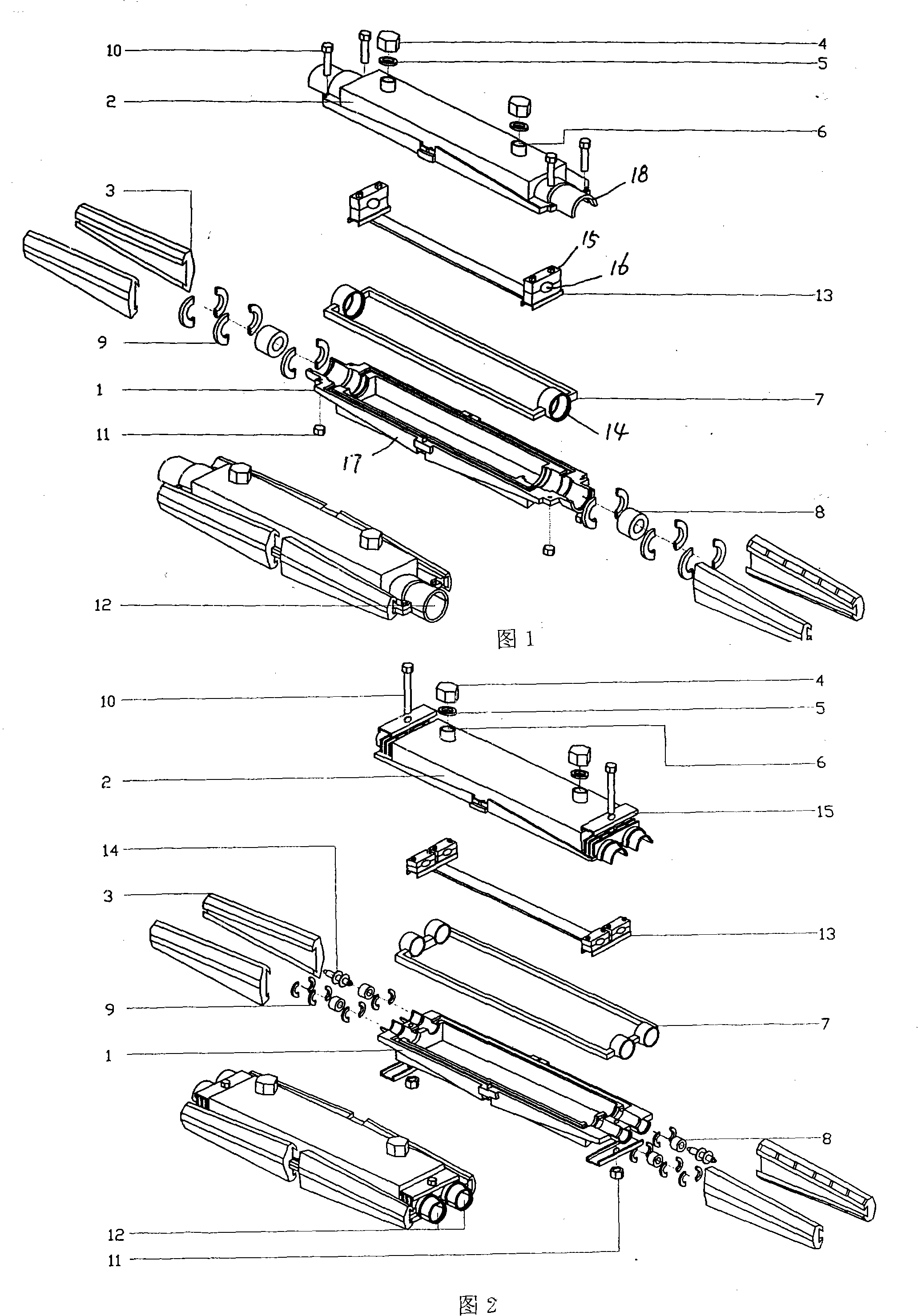

[0025] Example 1: Straight-through Cable Splice Box

[0026] The two ends of the box body 1 and the box cover 2 respectively have a semicircular ring 18 to form a cable inlet 12 . A rubber ring 14 is respectively arranged at both ends of the rectangular sealing ring 7 and is located in the cable inlet 12 . There are two holes 6 on the lid to cooperate with the blocking cover 4, one as a filling hole and the other as an air outlet. There is rubber reducing sleeve 8 in the rubber ring 14, and retaining ring 9 is arranged at the two ends of reducing sleeve. Back-up ring 9 has two broken grooves along the diameter. A support 13 is arranged in the box to be connected with the cable clamp 15.

[0027] During use, the cable ends that have been cleaned up are fixed on the support 13 with screws and cable clamps 15 . The inner diameter of the reducing sleeve 8 is 1mm-1.5mm smaller than the outer diameter of the cable aluminum sheath. The sections of the rubber ring 14 and the redu...

Embodiment 2

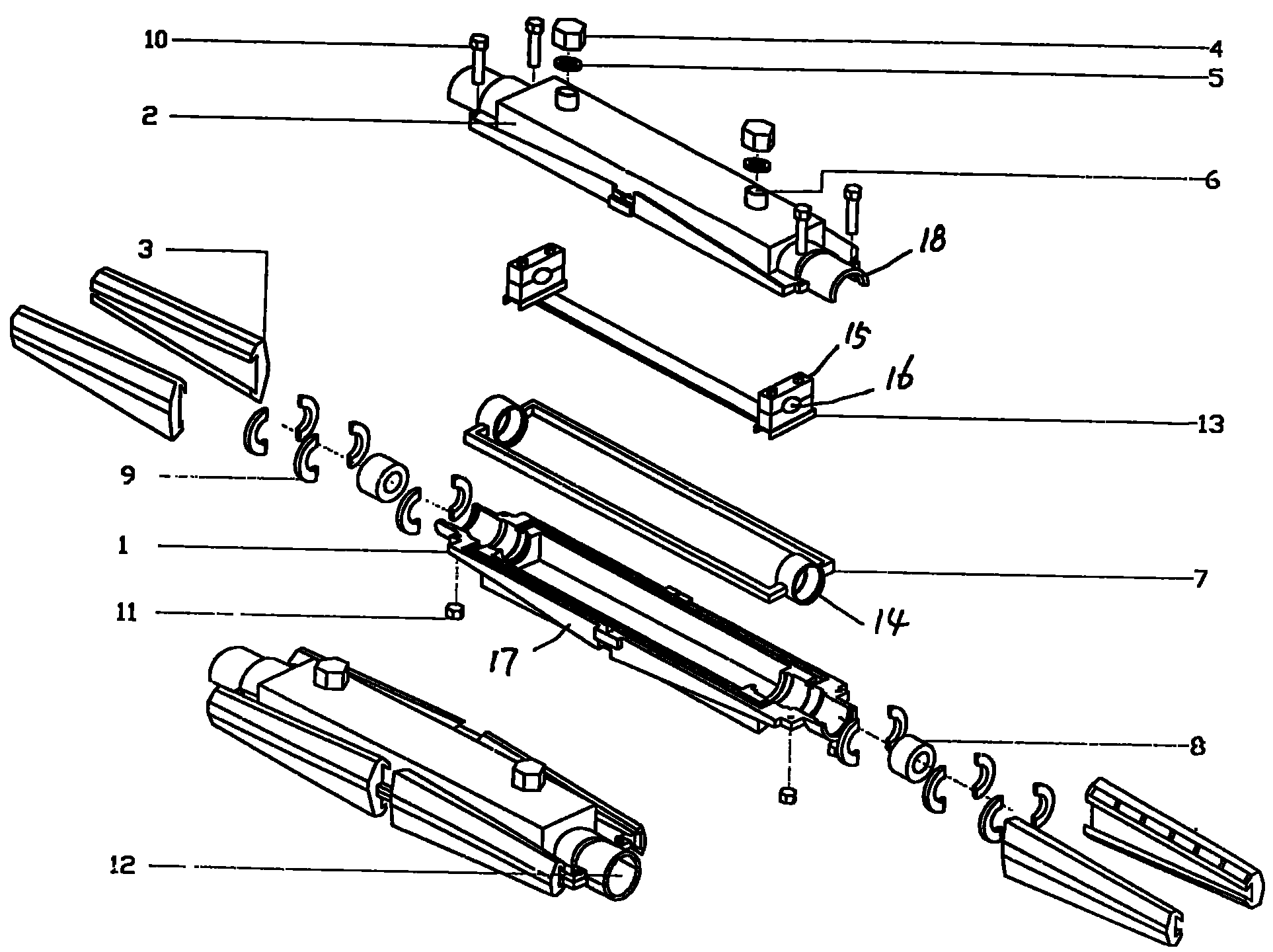

[0029] Embodiment 2: branched cable splice box

[0030] Two semicircular rings 18 are respectively arranged at two ends of the box body 1 and the box cover 2 to form two cable inlets 12, and two rubber rings 14 are respectively arranged at the two ends of the rectangular sealing ring 7 to be positioned in the cable inlet, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com