Methods for low cost manufacturing of complex layered materials and devices

A device and manufacturing process technology, applied in the field of composite layered materials and device manufacturing, can solve problems such as restricting the applicability of reel-to-reel production methods, restricting product design, and having no outer surface, so as to reduce R&D execution costs and improve productivity. , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

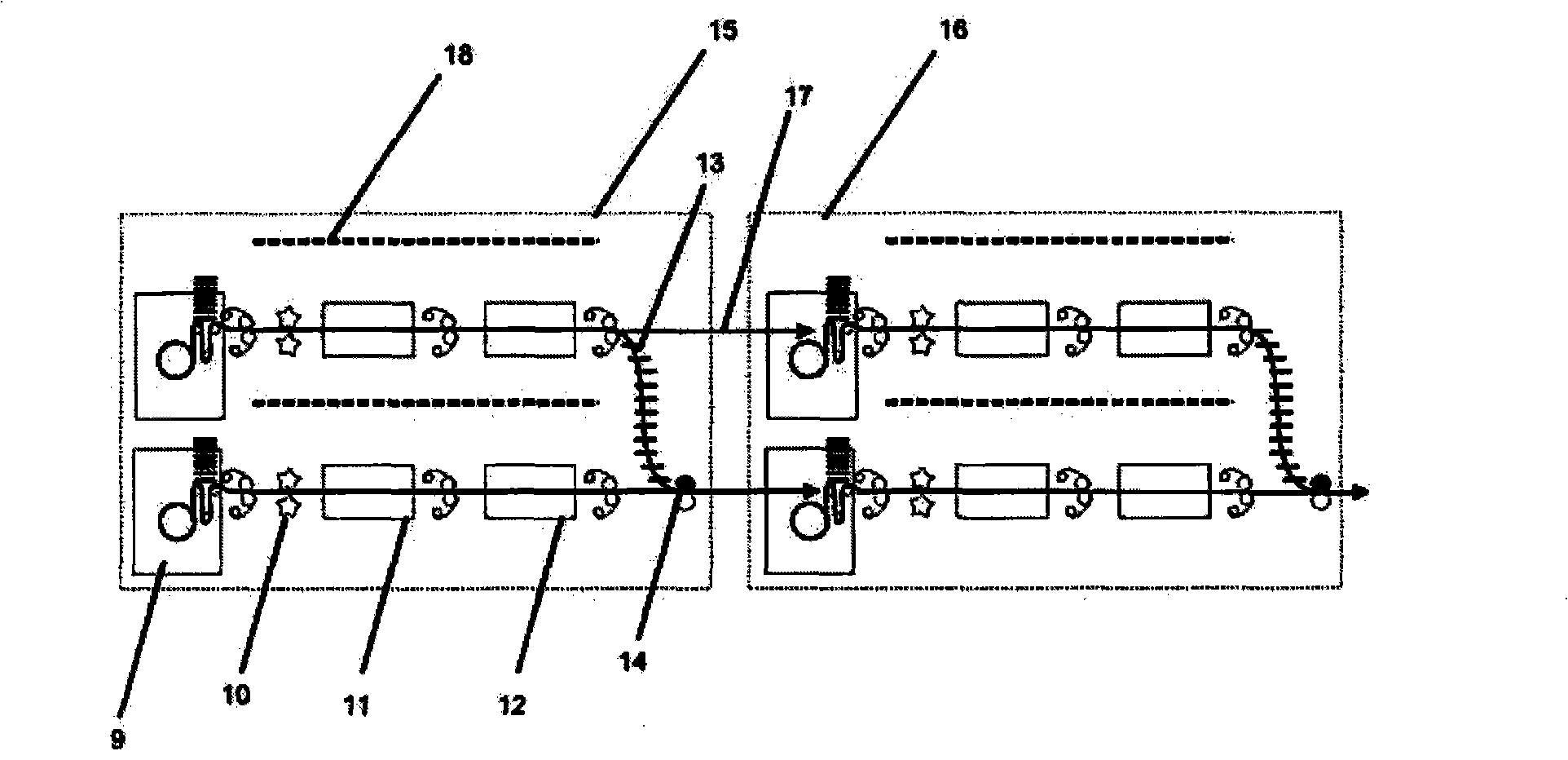

[0131] The invention is described herein with respect to the disclosed embodiments in relation to microfluidic devices. However, the invention is applicable to a wide variety of situations and products, and it should be appreciated that other configurations and arrangements are considered to be within the scope of the invention. Various modifications, alterations, changes and / or additions to the constructions and arrangements described herein are also considered to fall within the metes and bounds of the present invention.

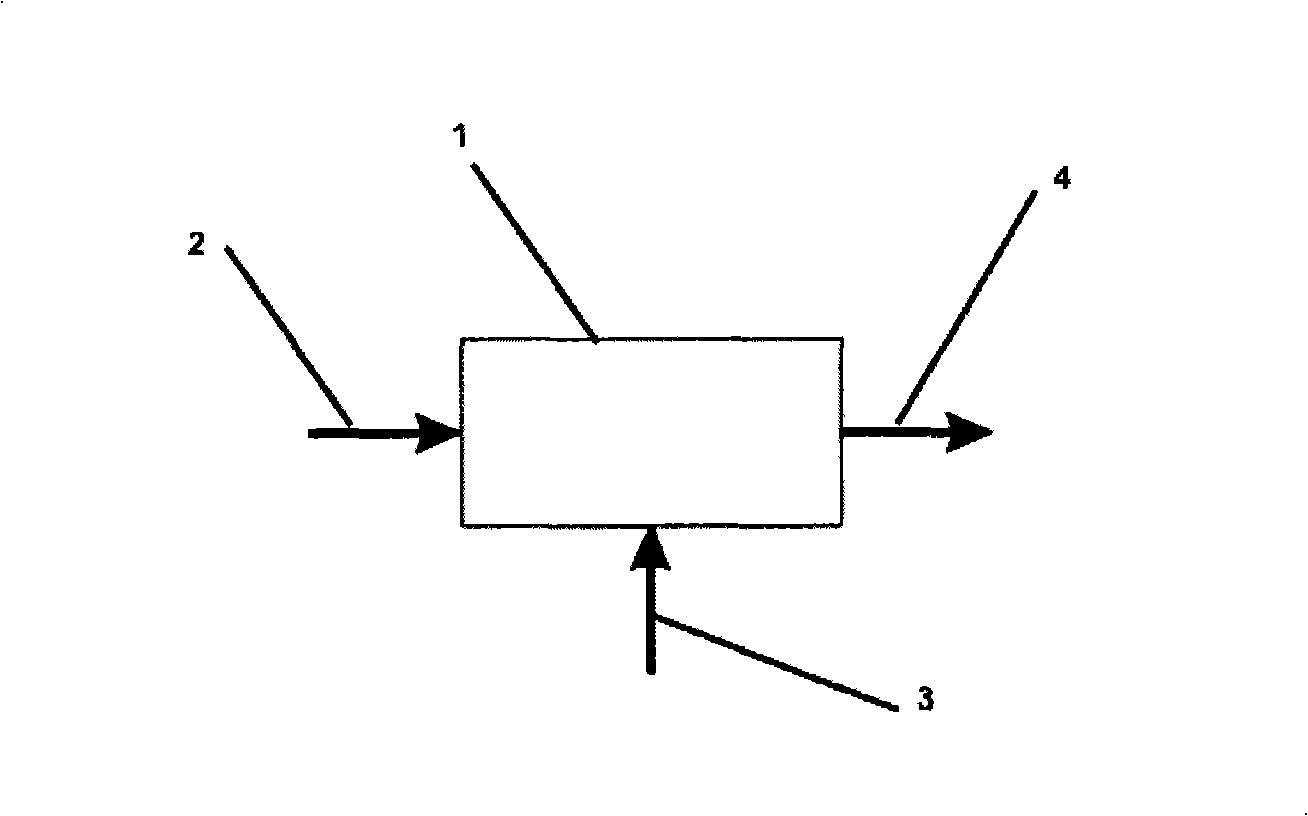

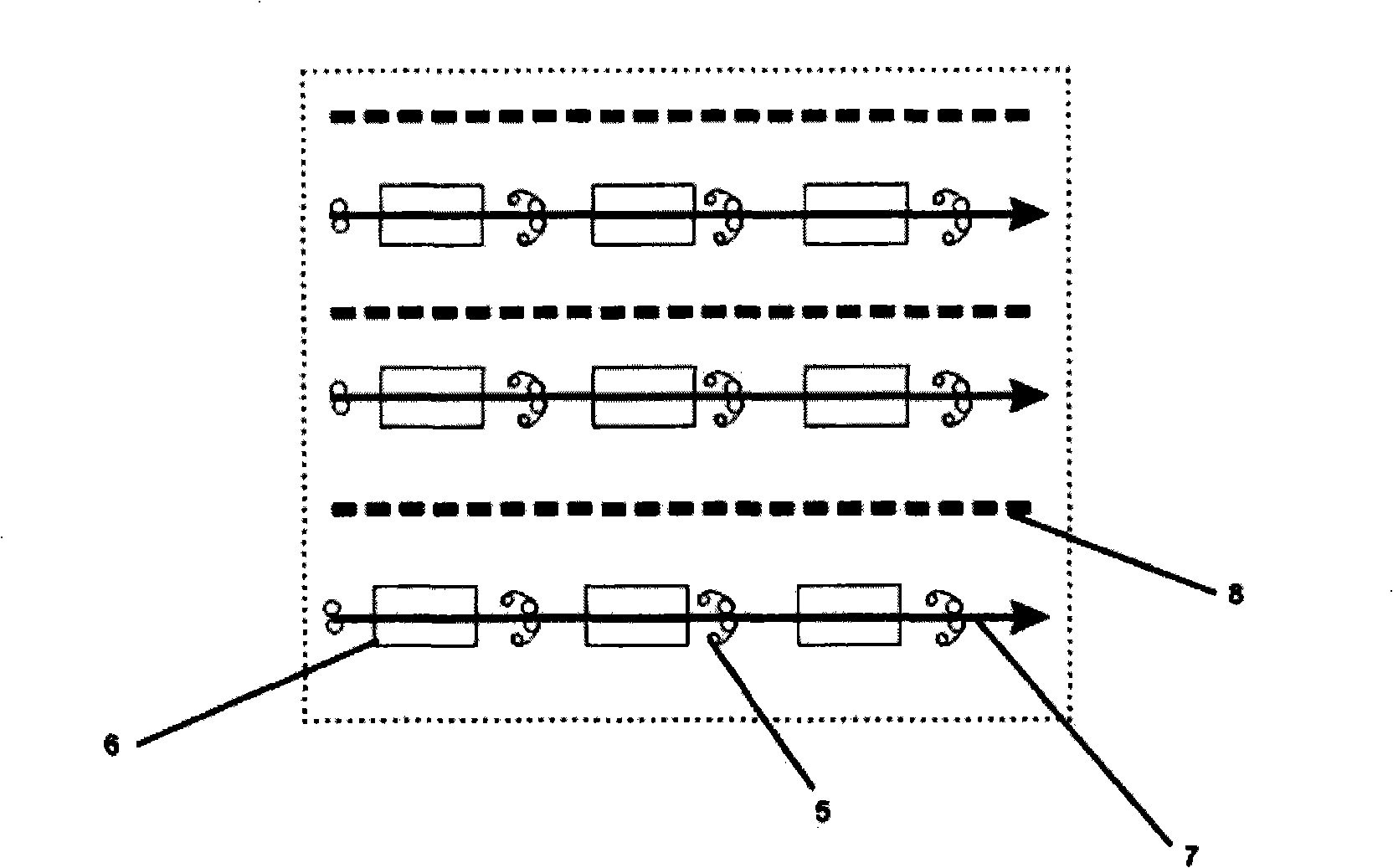

[0132] By combining reel-to-reel processing techniques and sheet handling systems into a flexible manufacturing strategy that can fabricate planar and non-planar devices of arbitrary thickness and with precise 3-dimensional surface and internal features, the manufacturing method of the present invention overcomes the aforementioned batch, serial and Limitations of reel-to-reel fabrication of layered materials and devices. Other novel manufacturing methods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com