Method for processing boiled mutton chop

A processing method and technology of mutton, applied in the field of food processing, can solve problems such as poor color, poor taste, and strong smell of white-cut mutton, and achieve the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Stew the old soup:

[0033] ① For the first cooking time, add mutton to the water, submerge the meat by 10 cm, boil the water on high heat, add 70 grams of salt, and wrap 100 grams of scallion white section, 40 grams of ginger section, and 10 grams of cumin with gauze. Boil in boiling water; cooking wine 10ml, rice wine 10ml

[0034] ②Boil the old soup for the second time, add a little water to the pot, return the old soup cooked for the first time to the pot, then add 100 grams of scallion white section, 40 grams of ginger section, and 10 grams of cumin, wrap them and add them Among them, it can be done after the fire is boiled.

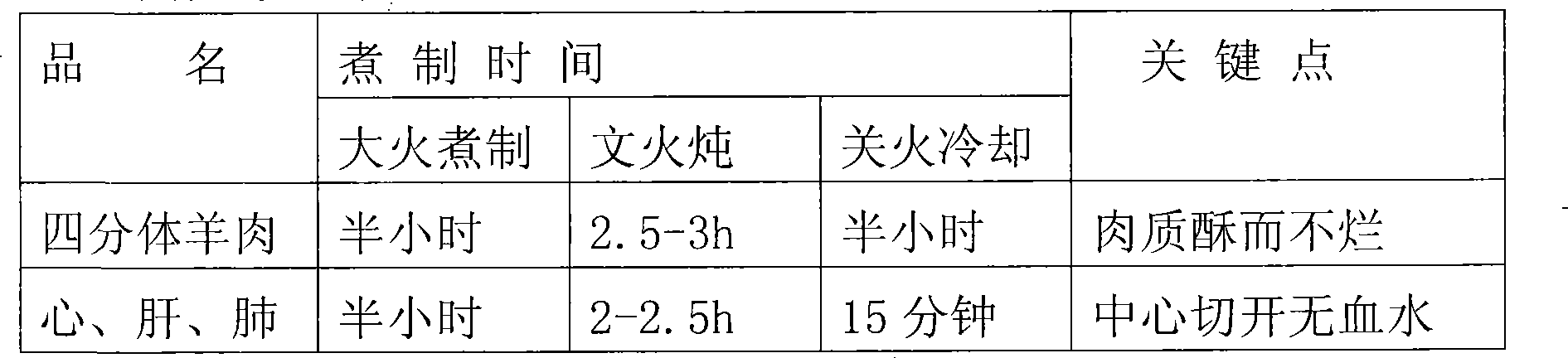

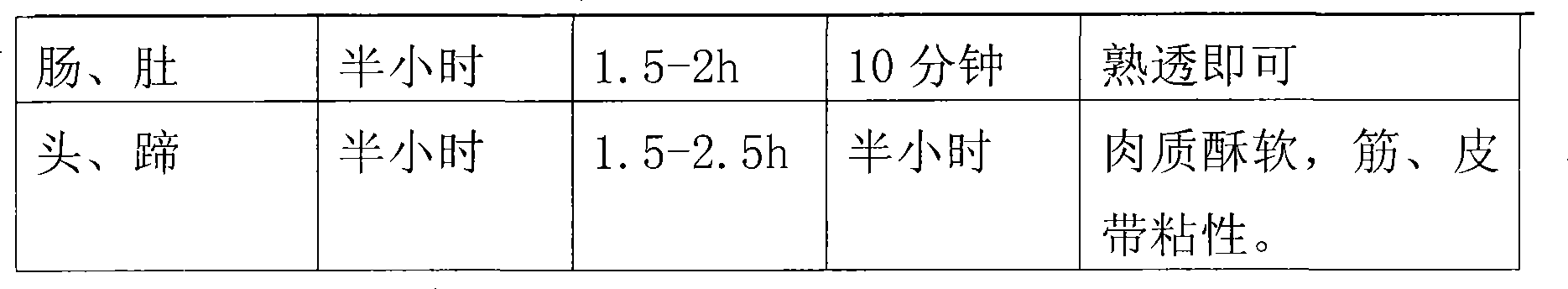

[0035] 2. Boiled mutton

[0036] Scald 10 kg of white striped sheep. The water temperature should reach 65-75°C during scalding, and the scalding time is 10 minutes; then pluck the hair backwards from back to front without leaving any dead ends. , head and hooves; then quarter the lamb carcass, then remove the large bones such as the ne...

Embodiment 2

[0038] 1. Old soup boiled

[0039] ① For the first cooking time, add mutton to the water, submerge the meat by 10 cm, boil the water on high heat, add 70 grams of salt, and wrap 100 grams of scallion white section, 40 grams of ginger section, and 10 grams of cumin with gauze. Boil in boiling water; cooking wine 10ml, rice wine 10ml

[0040] ②Boil the old soup for the second time, add a little water to the pot, return the old soup cooked for the first time to the pot, then add 100 grams of scallion white section, 40 grams of ginger section, and 10 grams of cumin, wrap them and add them Among them, it can be done after the fire is boiled.

[0041] 2. Boiled mutton

[0042] Scald 10 kg of white striped sheep. The water temperature should reach 65-75°C during scalding, and the scalding time is 10 minutes; then pluck the hair backwards from back to front without leaving any dead ends. , head and hooves; then quarter the lamb carcass, then remove the large bones such as the neck,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com