Gas-spreading device for aeration system

An aeration system and diffuser technology, applied in water aeration, fluid mixer, chemical instruments and methods, etc., can solve the problems of low perforation density, heavy use of basis weight, and difficulty in forming tiny perforations, etc. Dissolved oxygen rate, the effect of increasing the air outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

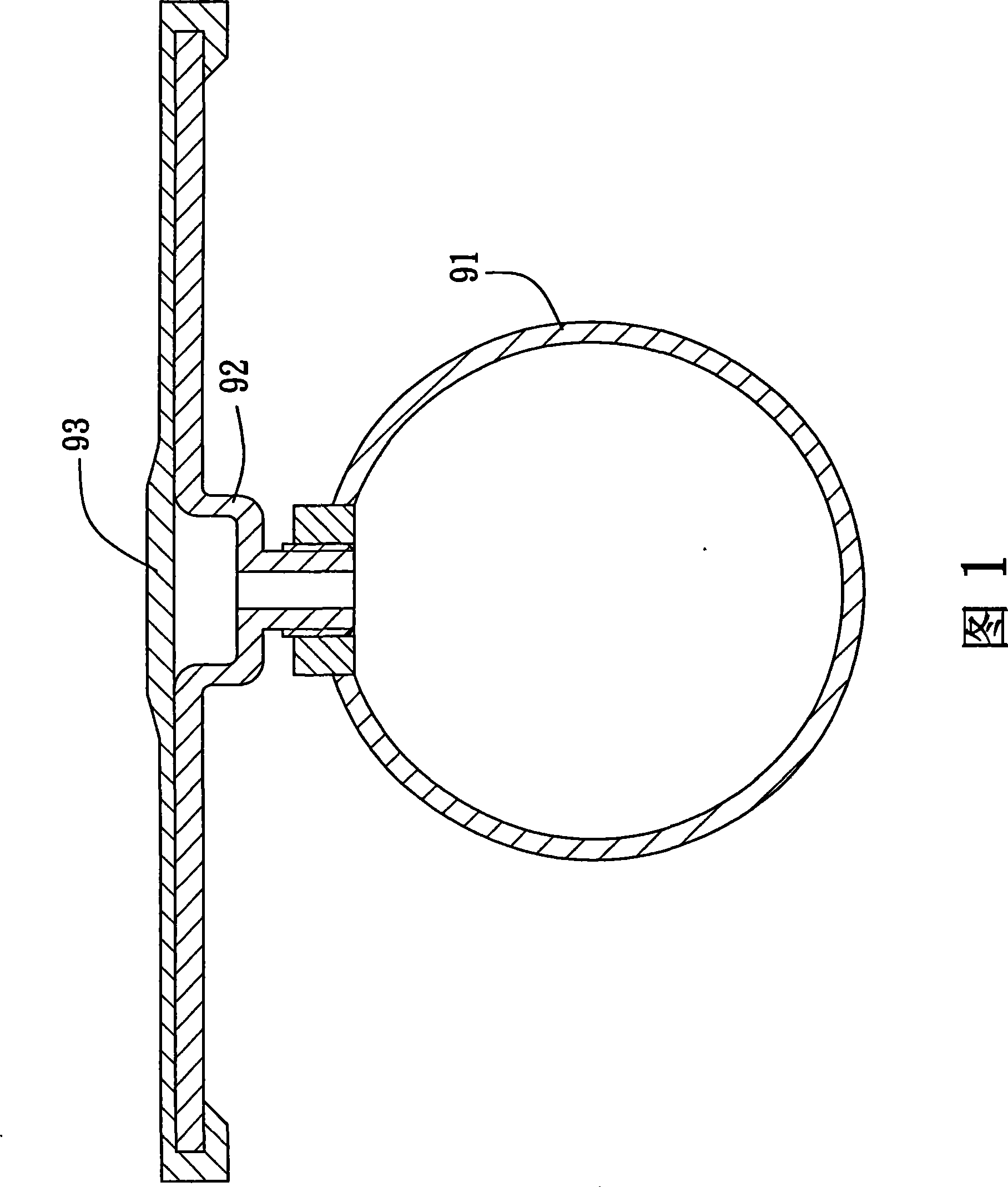

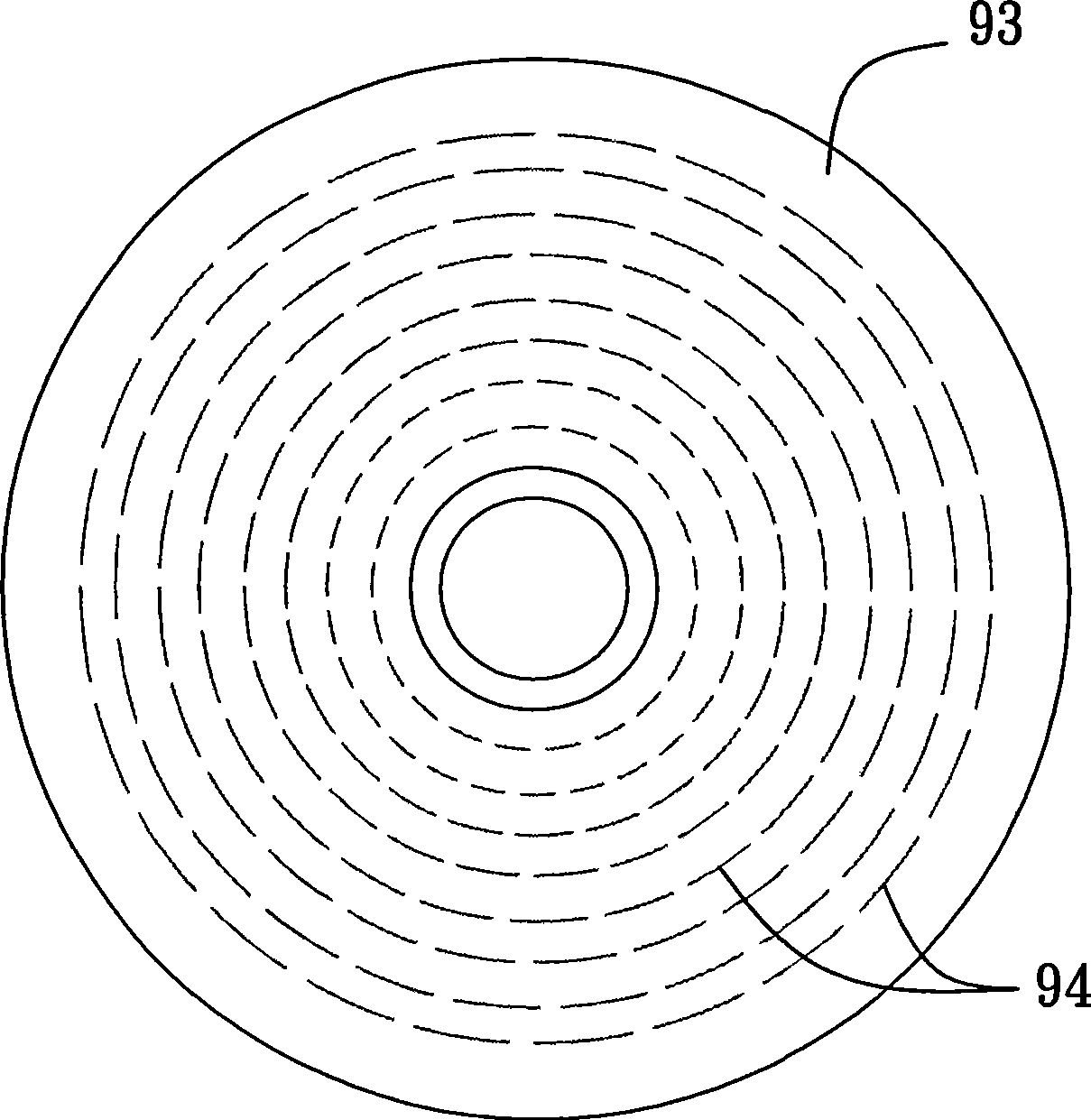

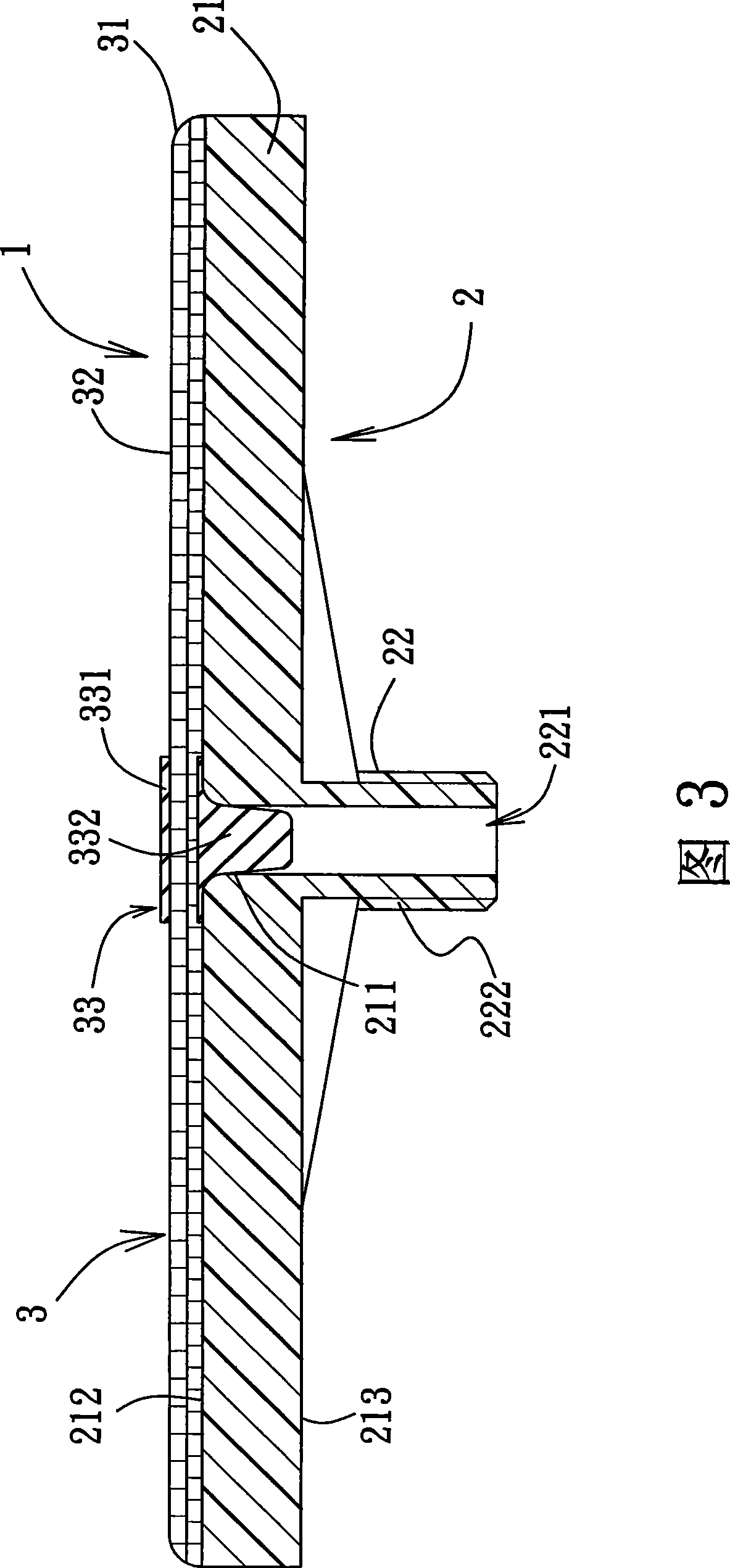

[0020] As shown in Figure 3, Figure 4 As shown in FIG. 5, the first preferred embodiment of the diffuser for the aeration system of the present invention is illustrated. The diffuser 1 of the first preferred embodiment of the present invention includes a base 2 , a gas diffusion membrane 3 and a check valve 33 . The base 2 includes a circular carrying plate 21 and an air inlet pipe 22. The center of the carrying plate 21 is formed with an air injection hole 211 and has a carrying surface 212. The air intake pipe 22 is connected to the opposite side 213 of the carrying surface 212 of the carrying plate 21. It also has a channel 221 communicating with the air injection hole 211 , and the outer wall of the air intake pipe 22 is formed with threads 222 for locking with an air delivery pipe 81 . The gas diffusion film 3 is disposed on the carrying surface 212 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com