Superfine ceramic thermal spray feedstock comprising ceramic oxide grain growth inhibitor and methods of making

A technology of ceramic oxide and grain growth, applied in the field of synthesizing this composition, thermal spraying raw material composition of ceramic oxide, can solve problems such as production obstacles of ultra-fine coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Boric acid (H 3 BO 3 ) and urea ((NH 2 ) 2 CO), WI for accommodation. Initially, 61.831 g (1 mol) of boric acid and 63.784 g (1.062 mol) of urea were dissolved in 1 liter of deoxygenated water. After thorough mixing, the aqueous solution was slowly heated to 90°C. Ammonia was bubbled into the solution with vigorous stirring until the solution was strongly basic. After 4 hours of reaction, the water was removed by distillation, leaving as a residue a polymeric precursor weighing about 80 g in the form of an agglomerated solid. It is hypothesized that in the presence of ammonia, boric acid reacts with urea to form poly-urea-boron complexes. The boron nitride precursor is a gelatinous white resin, highly soluble in water, which is easily ground into a powder. In the presence of ammonia, when heated to higher temperatures, the gel begins to melt at about 200°C, forming a foamy glass-like material, which transforms into white powder form of BN when heated to about 500...

Embodiment 2

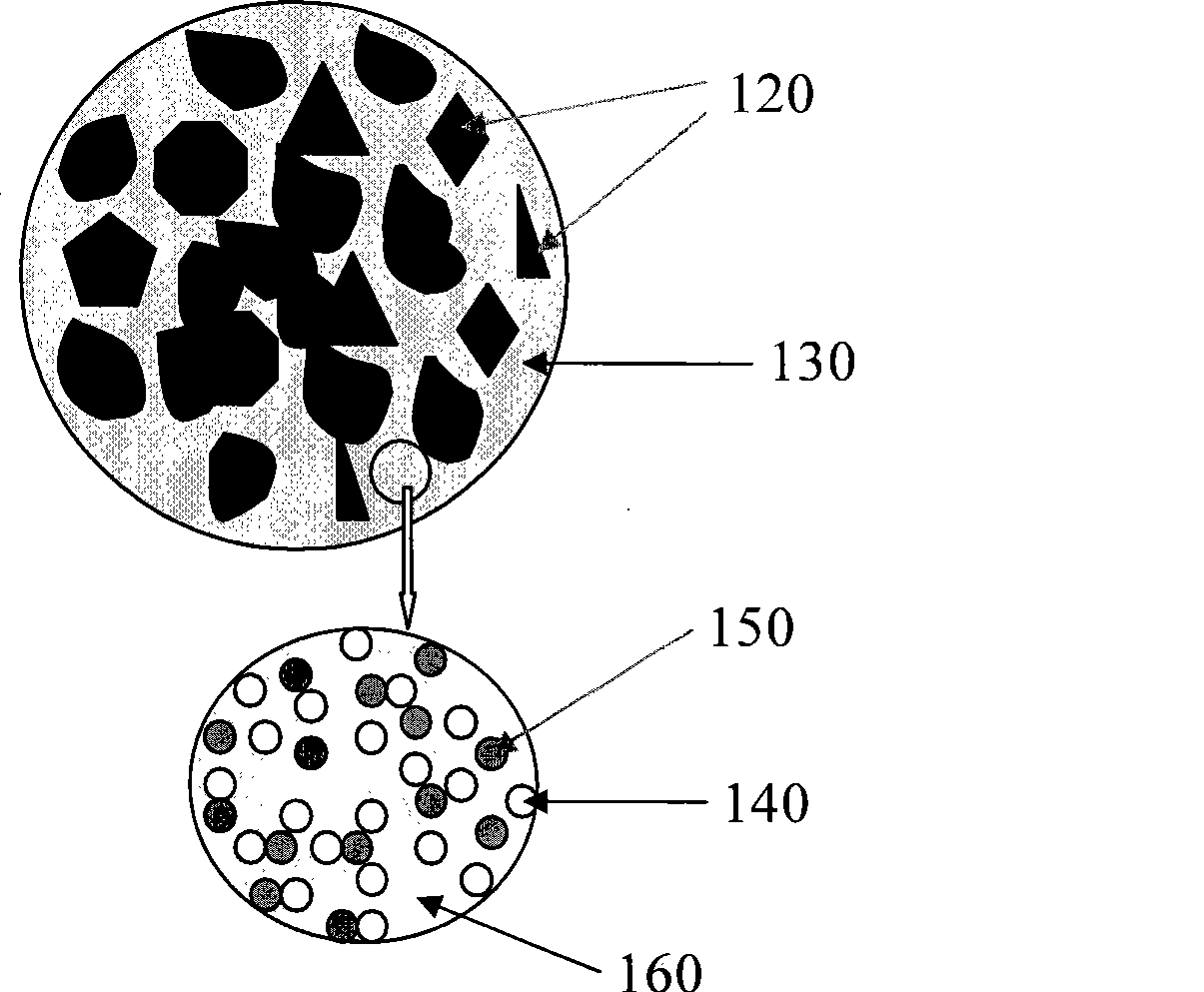

[0059] Synthesis of known quantities of BN polymerized precursors as described in Example 1 was first dissolved in distilled deionized water to make a nearly saturated solution. The solution was then combined with hollow tube nanostructured WC-Co (using the original sample from Nanodyne, Inc., New Brunswick, New Jersey) and ball milled to produce a slurry. The milled slurry was then dried in an oven at about 100°C to remove water. A number of samples were prepared in which the mole percentage of boron in BN was 0.1%, 0.25%, 0.5%, 1%, 2%, 5% and 10%. Converted to weight percentage (wt.%), these values are respectively equivalent to 0.006wt.%, 0.015wt.%, 0.03wt.%, 0.06wt.%, 0.119wt.%, 0.293wt.% and 0.569wt.% Boron in BN.

Embodiment 3

Example 3: Sintering of Precursor / Nanostructured Material Intermediate

[0060] The ground sample of Example 2 (which is also the sample of the original sample of WC-Co powder) was sintered first by initially pressing about 10 g of each sample into a 1.5 cm disc, and then using a heating rate of 10 °C / min under flowing argon Each sample was heat treated at 1400°C under air for 0.5 hours. After heat treatment, the resulting platelets shrink to about half their original size and densify to varying degrees, up to about 99% density.

[0061] The plots of Vickers hardness values (VHN, 300g) for these samples are shown in the attached Figure 4 middle. The average hardness of the sample with 0.0wt.% boron is about 2135, and the highest value reaches 2228. All of these samples were fairly tough. For example, when measuring conventional WC-Co (which has a VHN of 1200 to 1600), cracks always appear at each diamond-shaped notch turn. In any of the samples examined, no obvious crac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com