Method and device for designing wedge-type mounting floating rail vibration damping noise reduction fastener

A technology of vibration reduction and noise reduction and floating rail, which is applied in the field of rail vibration reduction and noise reduction, can solve the problems of increasing the lateral amplitude of the rail and affecting the safety of driving, and achieve the effect of reducing the installation height, light weight and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

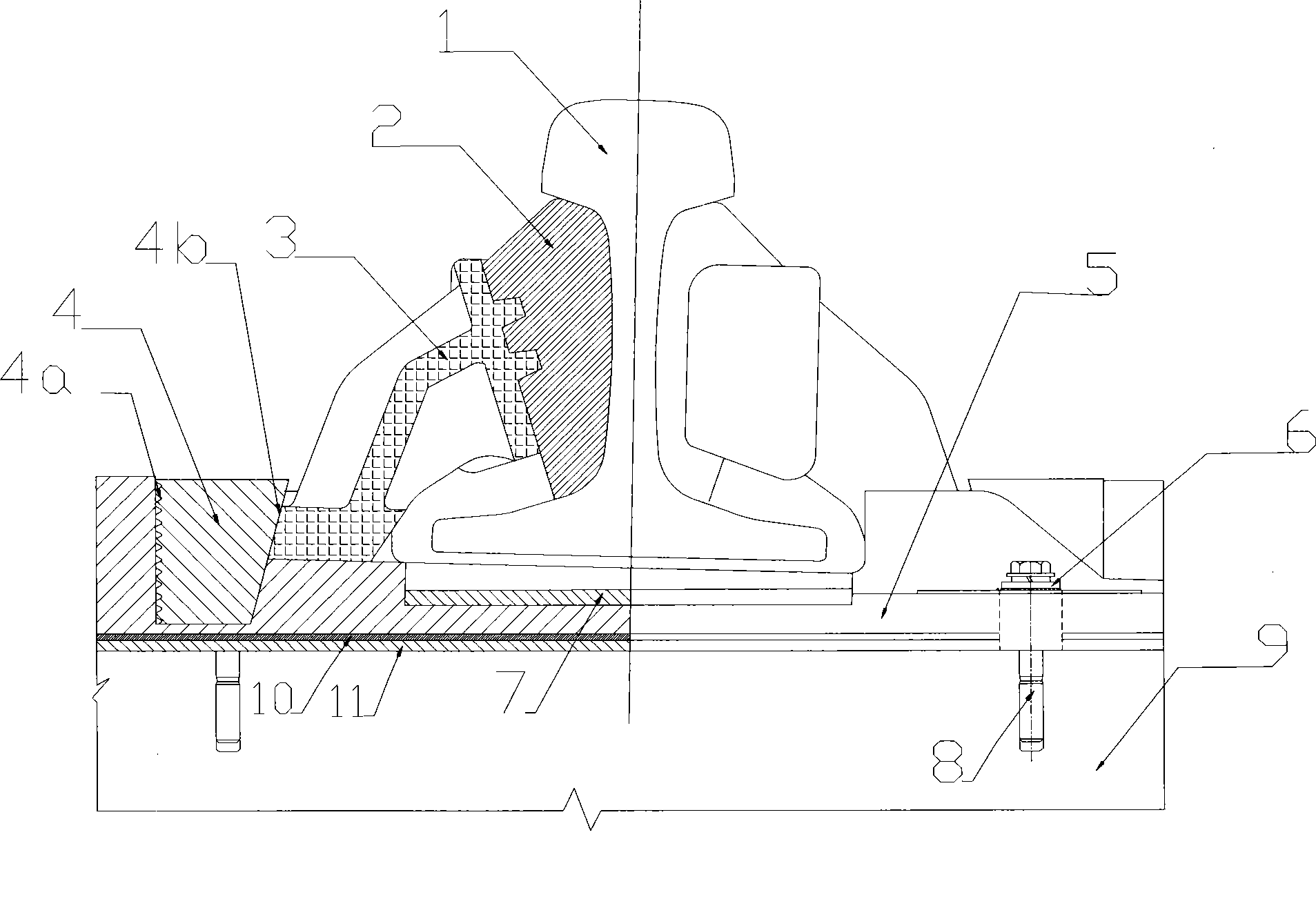

[0023] The design method of the wedge-type installed floating rail vibration and noise reduction fasteners of the present invention is that polymer elastic parts are symmetrically arranged on both sides of the rail waist, and the end face radian matches the rail side radian, and the other end face is provided with several sockets for installation. On the inverted V-shaped bracket, the steel rail is supported by the inverted V-shaped bracket. The bottom of the inverted V-shaped bracket is seated in the guide groove on the boss of the bottom plate, and is fixed by a wedge inserted into the groove of the bottom plate. The wedge and The contact surface of the bottom plate is a tooth surface, the contact surface of the wedge, the bottom plate and the inverted V-shaped bracket is an inclined (wedge) surface, and the two sides of the bottom plate at the inclined (wedge) surface are also inclined in the same direction, and the teeth of the wedge block The grained surface leans against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com