Method for discharging water and slag of coal mine deep hole

A technology for coal mines and deep holes, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve problems such as inability to reach drainage in holes, and achieve the effect of simple device control, simple operation, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

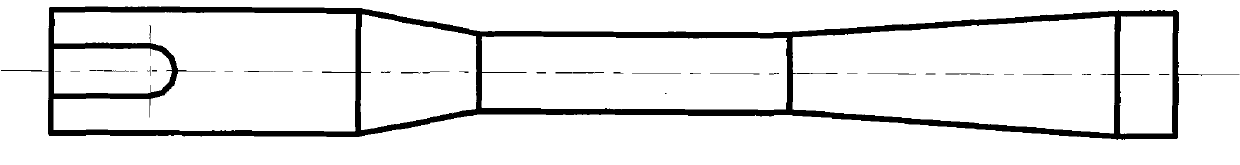

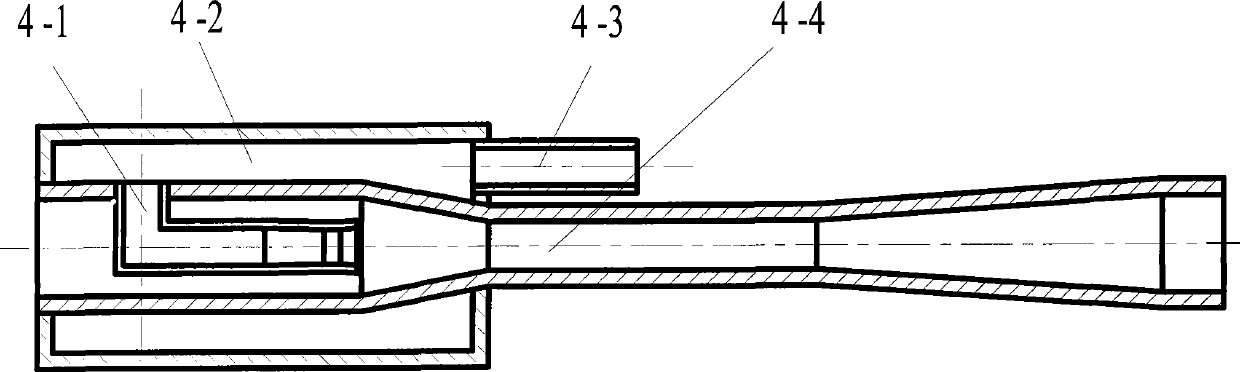

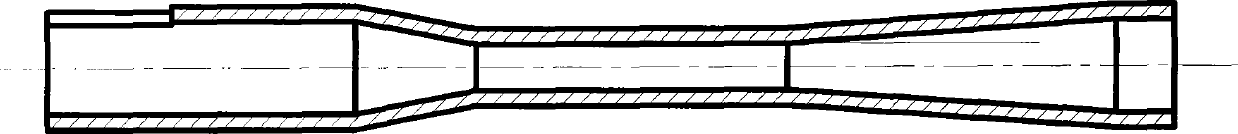

[0028] In conjunction with the accompanying drawings, the novel coal mine deep hole drainage / slagging method involved in the present invention is further described as follows:

[0029] The steps of the coal mine deep hole drainage / slag discharge method in the present invention are as follows: first, connect the drainage pipe 5 and the outlet of the drainage pump main body 4-4 firmly through a pipe clamp, and connect the outlet of the compressed air station 2 with an air supply pressure of 0.5 to 0.8 MPa The compressed air nozzle 4-1 of the drainage pump is firmly connected with the compressed air pipe 3 with a pipe clamp; put the connected drainage pump 4 into the downward hole, and open the compressed air valve 1; after the drainage pump works normally, according to the on-site hole The size of the accumulated water, when it is observed that there is no accumulated water / cinder discharged from the drain pipe, it indicates that the drainage is complete, close the compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com