Ceramic wedge-type double-gate valves

A wedge and gate valve technology, applied in the field of ceramic wedge valves, can solve the problems of reducing the service life of the valve plate, reducing the valve sealing performance, frequent maintenance and replacement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

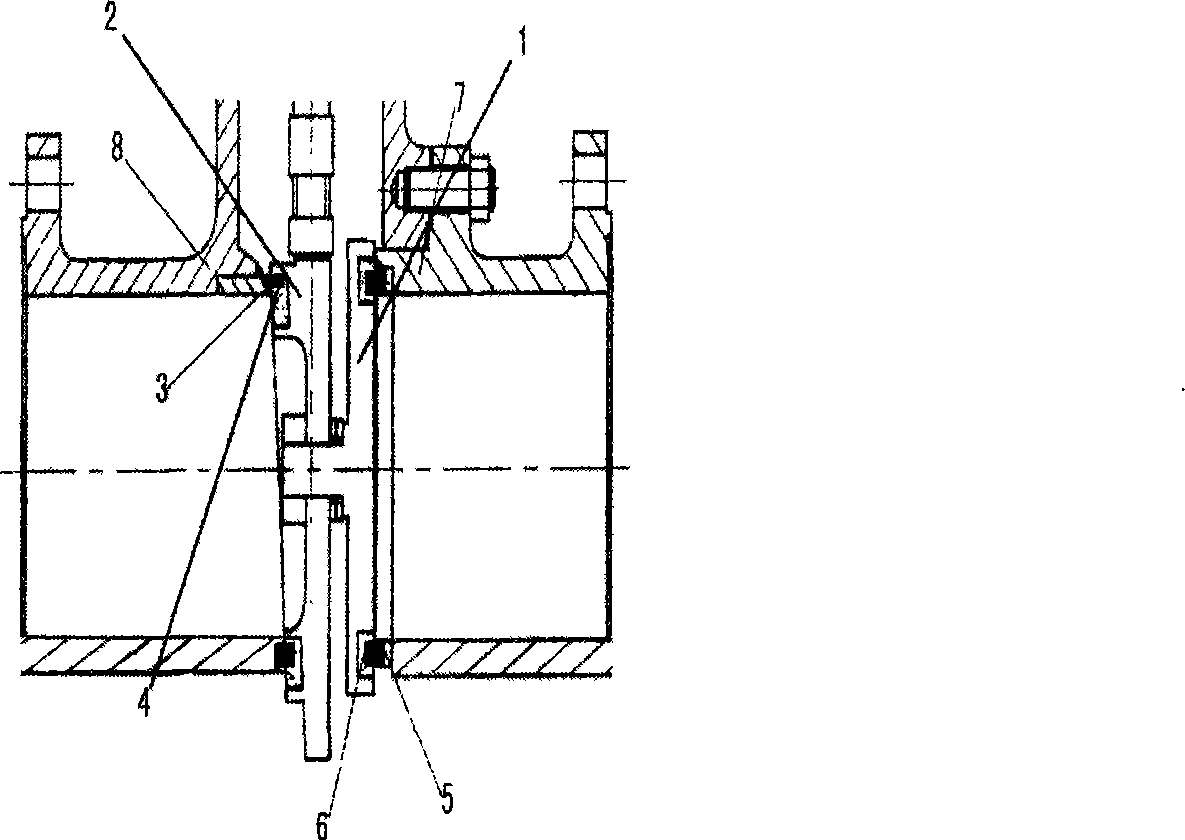

[0011] according to figure 1 As shown, the valve bar 7 is provided with a ceramic sealing ring at the contact part of the main valve plate 1 and the auxiliary valve plate 2, and the contact part of the valve bar 7 with the main valve plate 1 and the auxiliary valve plate 2 is provided with a ceramic sealing ring 3-6. According to the surface structure of the main and auxiliary rams, it is set as a, b, c, d four. In the process of opening and closing, the ceramic ring isolates the metal from the medium, so that the medium with high hardness and high corrosiveness is in contact with the high-hardness ceramic ring, which greatly improves the wear resistance of the valve and greatly improves the valve's durability. The service life really guarantees the continuous normal operation of the plant.

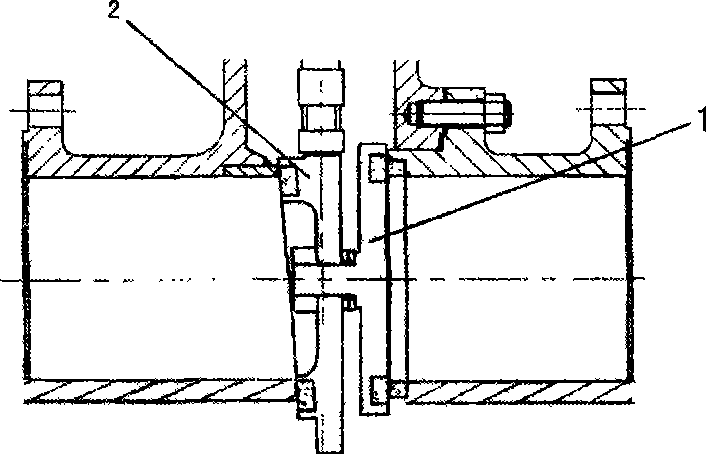

[0012] figure 2 Because the valve is in the closed state, because the auxiliary valve plate 2 adopts a wedge-shaped structure with an inclined angle, the valve plate and the main valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com