Three chain-riveting type incising stitching instrument

A stapler and staple technology, which is used in surgical fixation staples, medical science, surgery, etc., can solve the problems of the heavy head of the cutting stapler, the loss of ultra-low rectal cancer patients, and the increase of operation costs, and achieve a lightweight head. , easy to operate, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

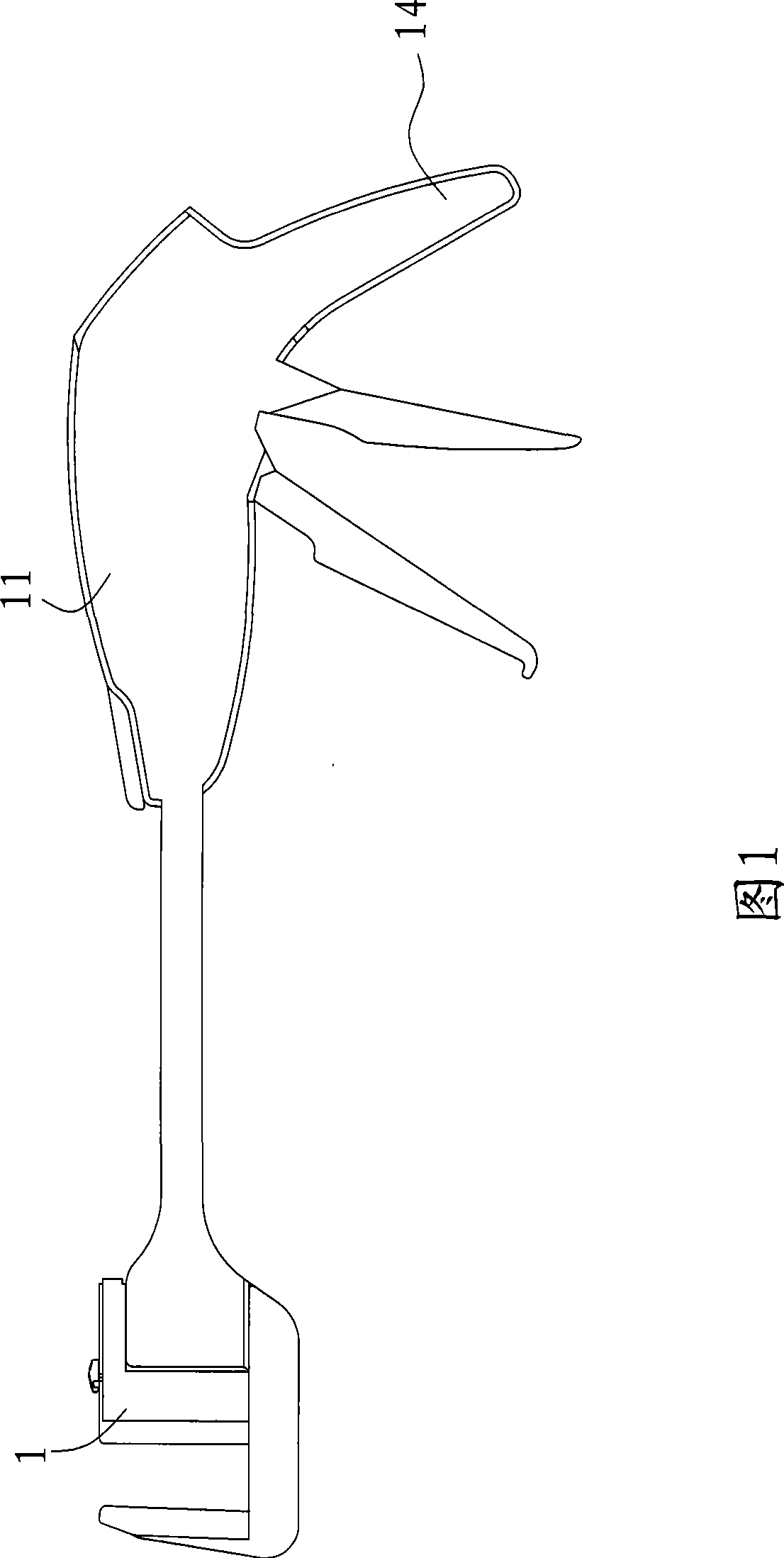

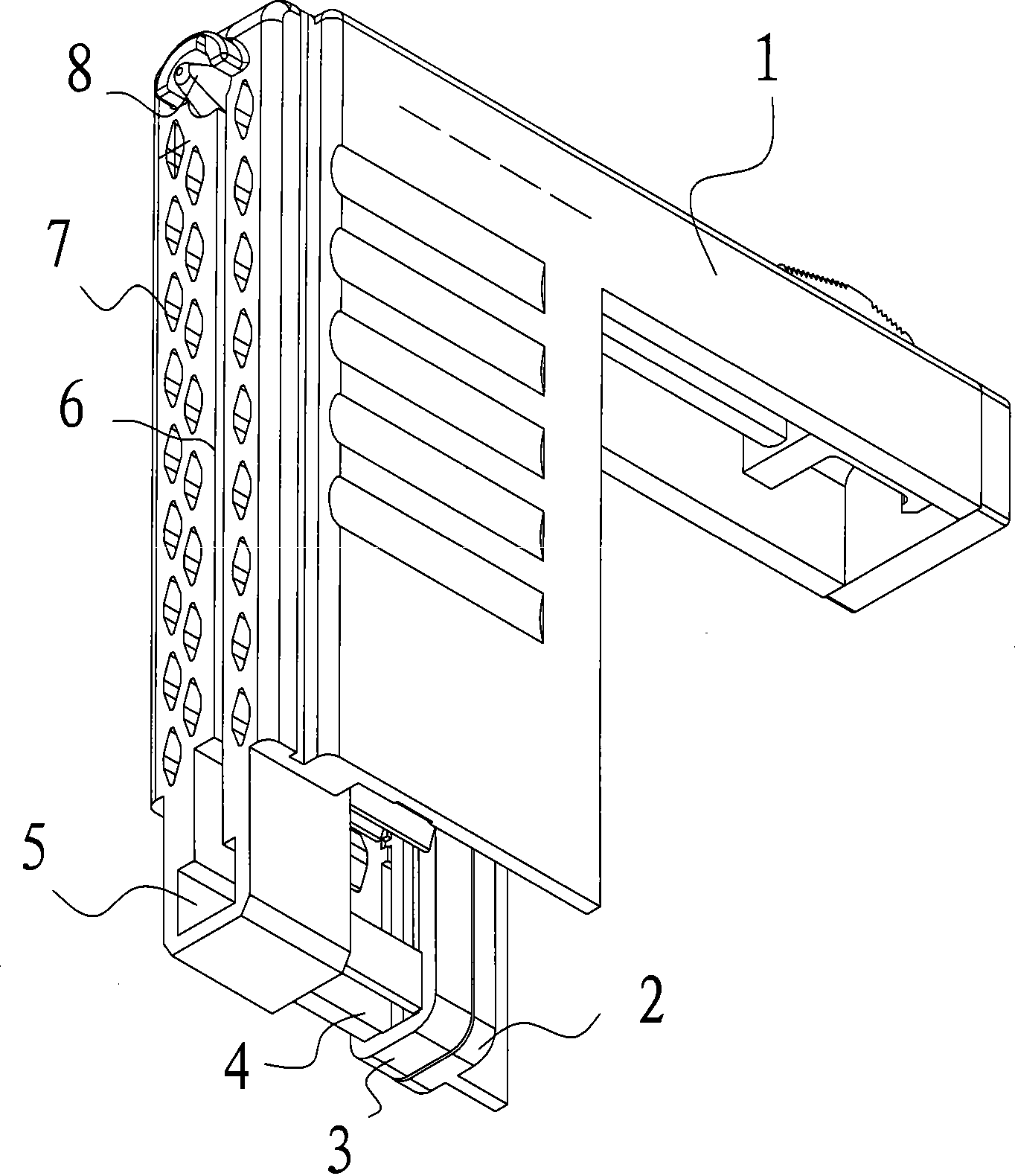

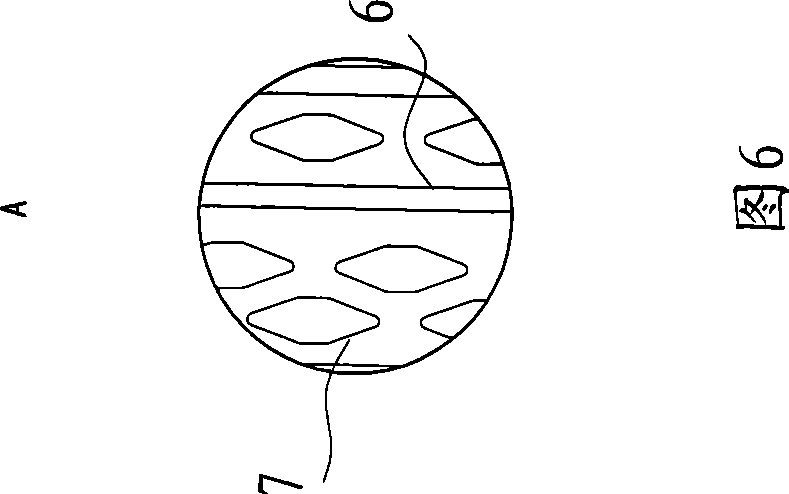

[0024] A three-row nail-type cutting and stapling device, as shown in Figure 1, includes a body 11, a handle 14 disposed at the rear end of the body 11, a staple bin 1 and a cutter 8 disposed at the front end of the body 11, a stapler disposed on the nail Inside the bin 1 is used to push the staple pusher 3 to move the staples. The staple bin 1 is provided with a plurality of nail holes 7 that allow the staples to pass through and a knife groove 6 that allows the cutting knife 8 to pass through, as shown in Figure 5 As shown, the nail holes 7 are arranged in three parallel rows on the nail cartridge 1, and three parallel rows of nail seats 9 are arranged on the positions corresponding to the nail holes 7 on the nail pushing piece 3.

[0025] The three rows of nail holes 7 in this embodiment are separated by the knife groove 6 , one row of nail holes 7 is located on one side of the knife groove 6 , and the other two rows of nail holes 7 are located on the other side of the knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com