Improvement for rotorcraft equipped with turboshaft engines

A technology of rotorcraft and turbine engine, applied in aircrafts, engine components, machines/engines, etc., can solve the problems of high fuel consumption rate, money consumption, time consumption, etc., and achieve the effect of reducing fuel consumption rate and increasing driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

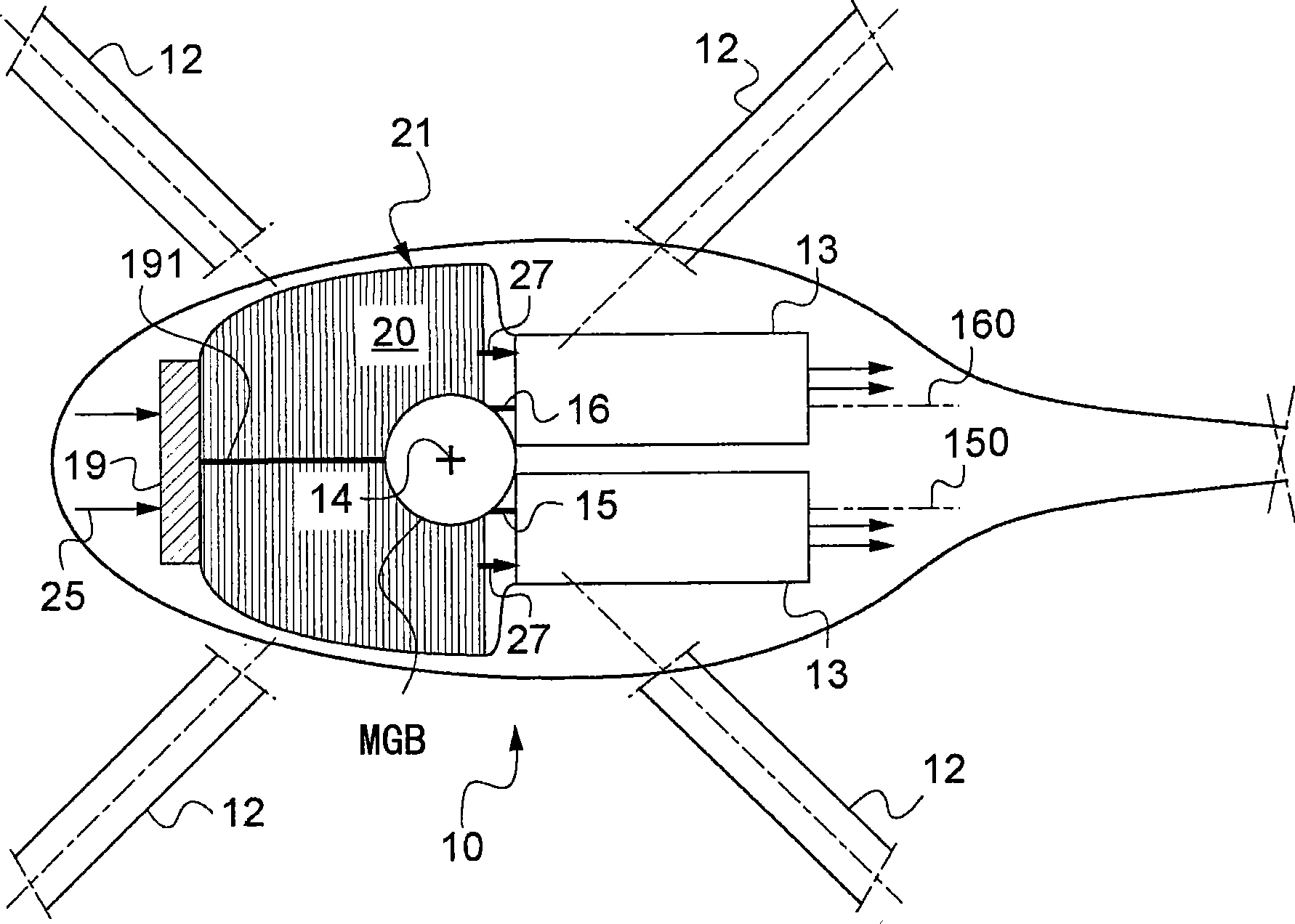

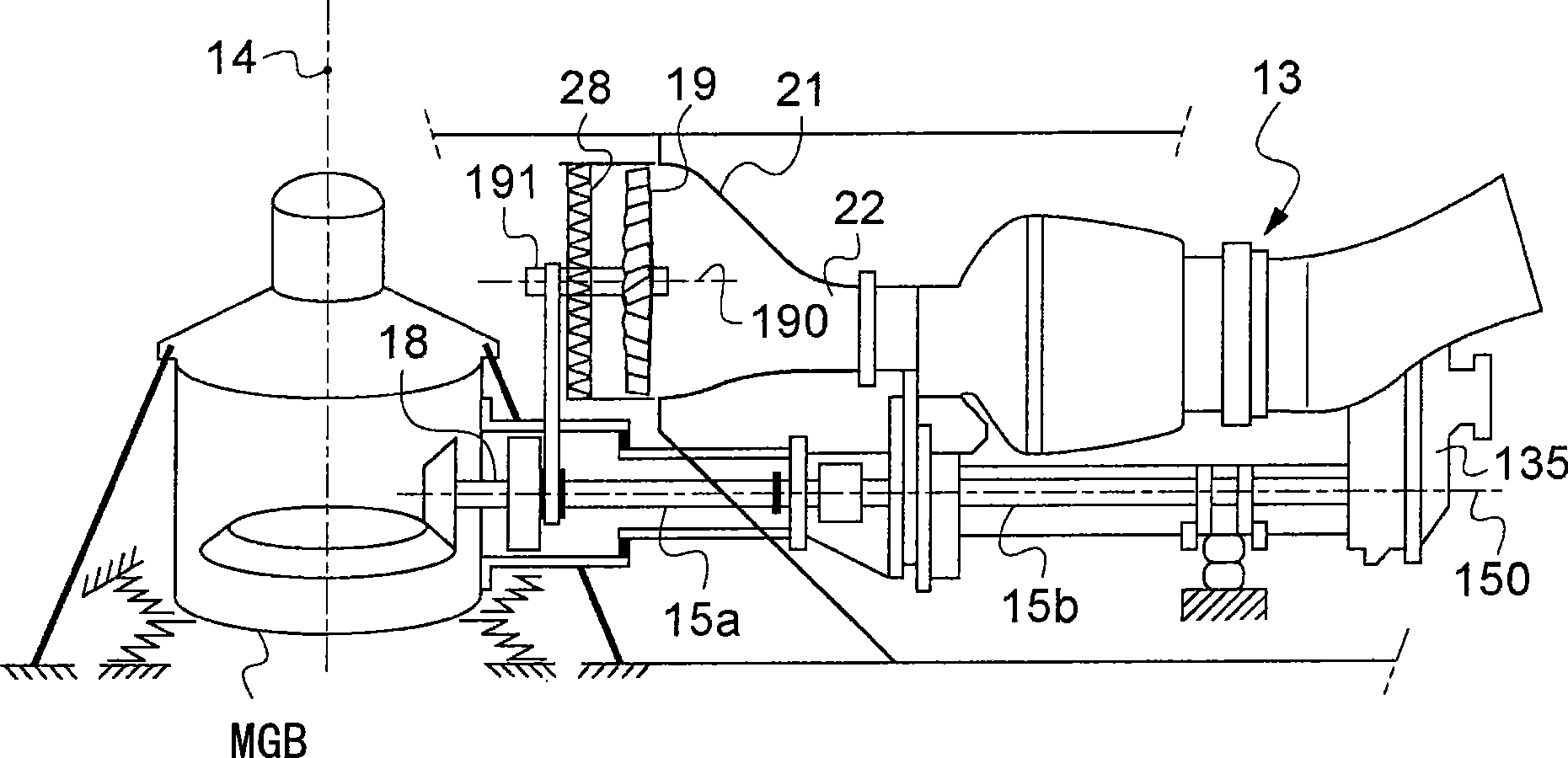

[0036] Reference figure 2 Up to 6, the present invention relates to helicopters 10 and other rotorcraft, on which at least one lift and propulsion rotor 11 equipped with blades 12 is driven by one or more turbine engines 13 to rotate about a substantially vertical axis 14.

[0037] The main gearbox (MGB) connects the output shafts 15 and 16 of each engine to the shaft 17 of the main rotor. This gearbox especially includes a reducer (see Figure 5 ).

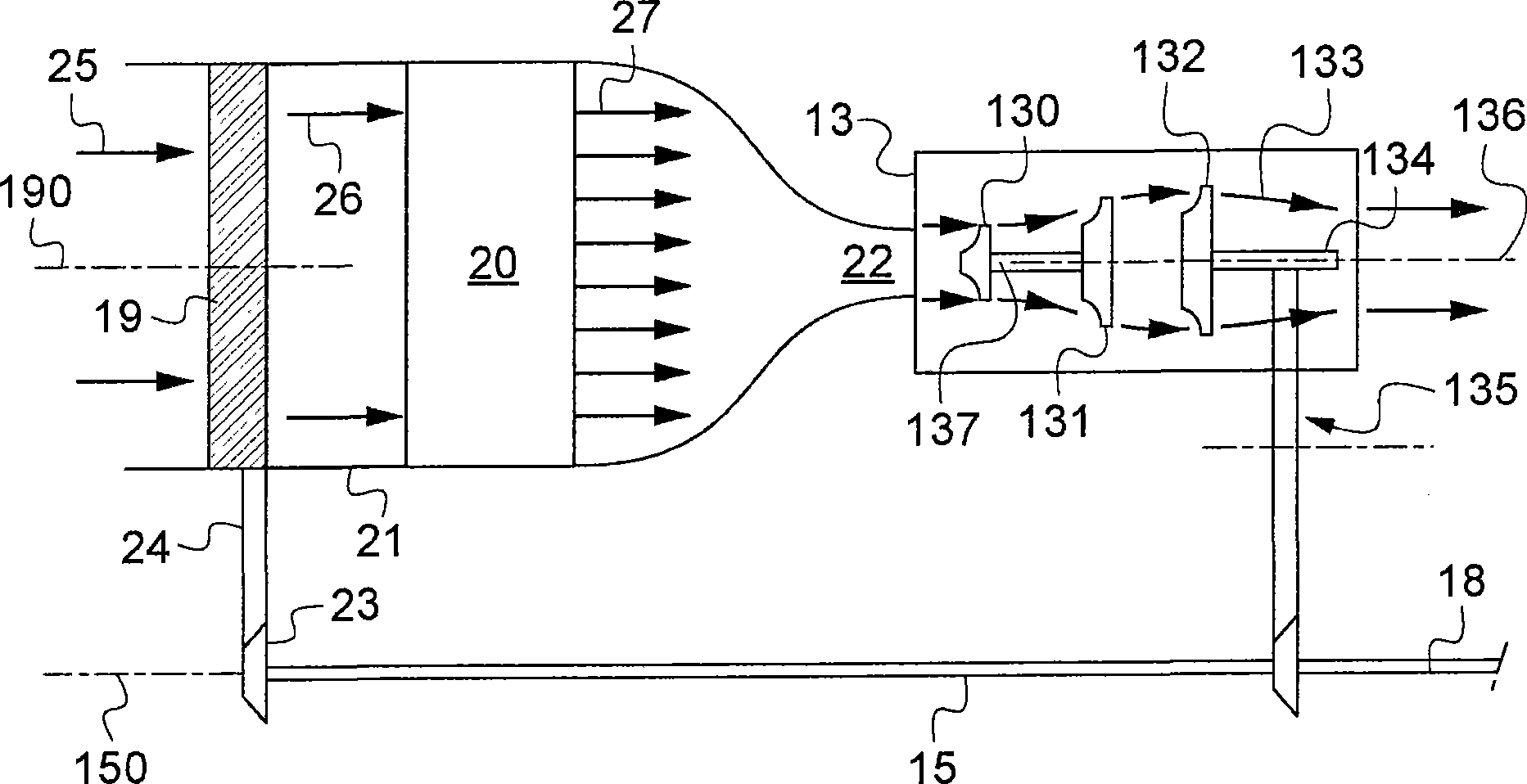

[0038] Such as figure 1 As shown, each engine includes an internal compressor 130 and a first turbine 131 constrained to rotate with the internal compressor 130. The engine also includes a free turbine 132, which is downstream of the first turbine relative to the direction 133 of gas flow through the engine.

[0039] The free turbine generates drive torque, which is transmitted by the shaft 134 of the free turbine, and then transmitted by the output shaft 15 of the engine via the reducer 135. This output shaft runs along the line pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com