Seat belt retractor and seat belt apparatus employing the same

A seat belt retractor and seat belt technology, which is applied in the directions of seat belts, belt tensioners, and energy-absorbing devices in the vehicle, can solve the problem of the increased installation space of the seat belt retractor 3 and the difficulty in rolling the seat belts. The compactness of the receiver 3 requires the requirements of the interior space of the vehicle, etc., to prevent the limit load from increasing rapidly, the structure is simple, and the axial length is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The best embodiments for carrying out the present invention will be described below using the drawings.

[0045] figure 1 It is a view which schematically and partly shows the seatbelt retractor which concerns on one Embodiment of this invention. In describing the embodiments below, the same reference numerals are used to denote the same structural components as those of the above-described prior art example, and detailed description is omitted.

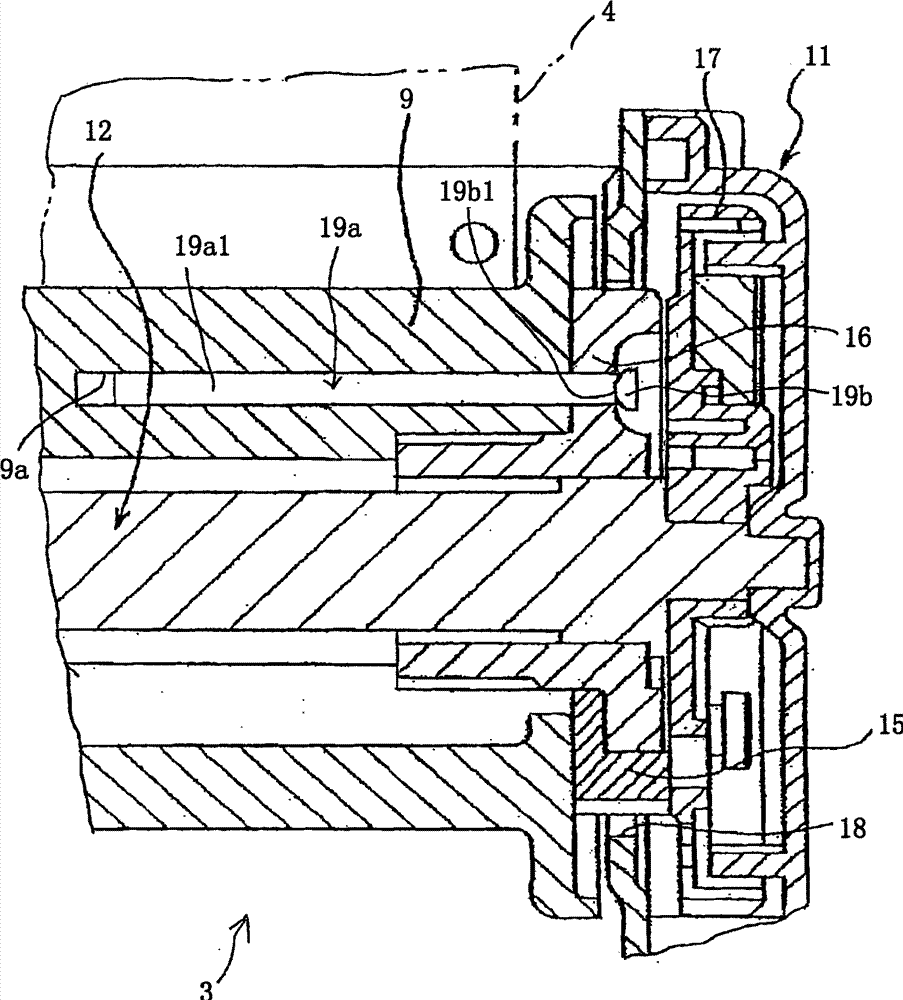

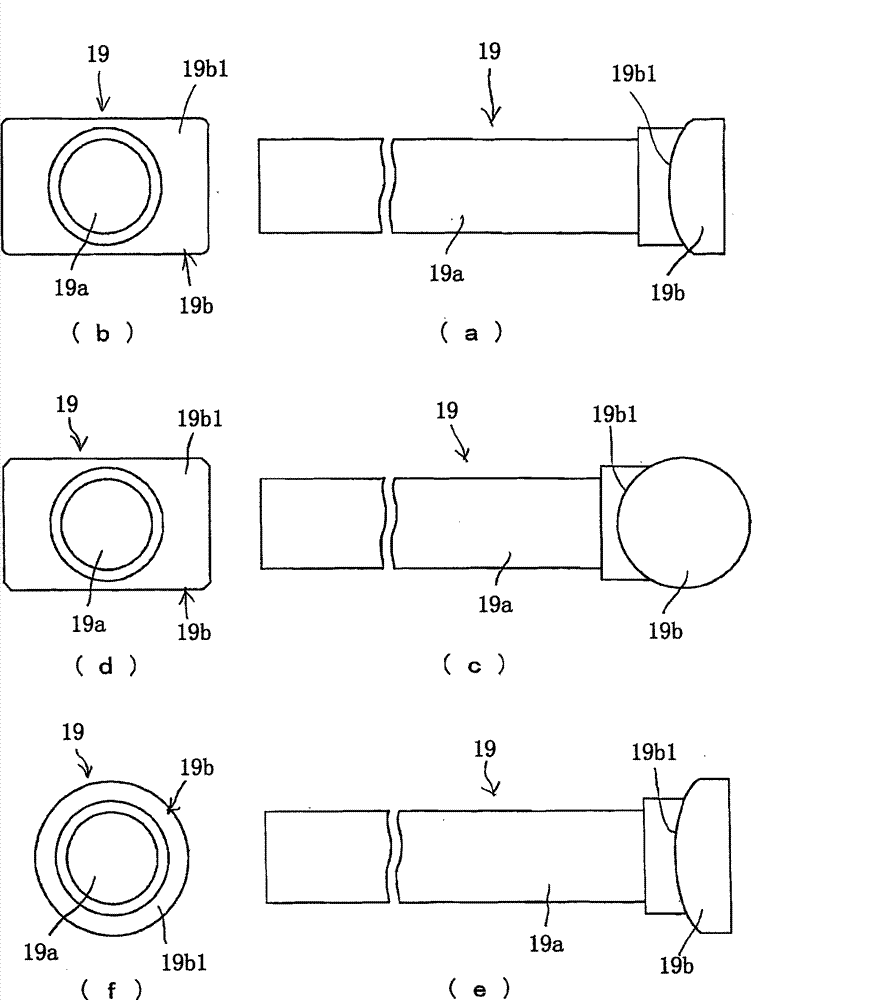

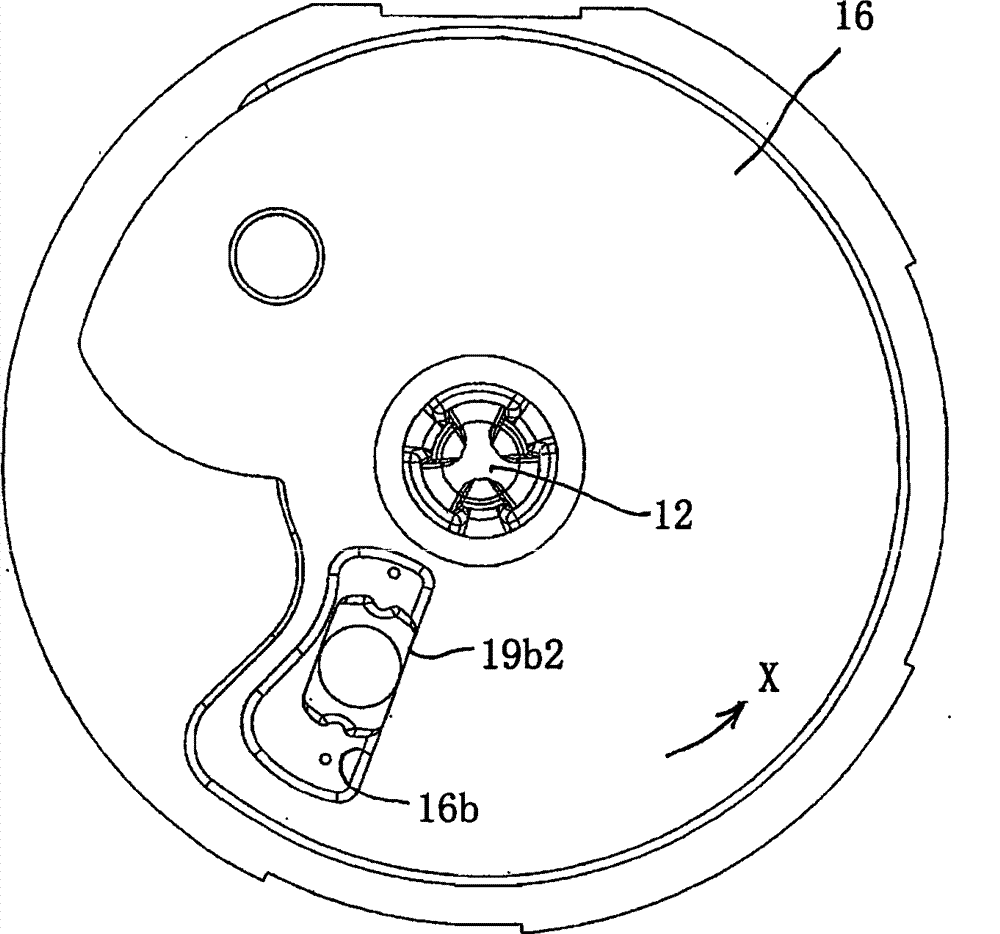

[0046] Such as figure 1 As shown, the safety belt retractor 3 of this example is the same as the above-mentioned Image 6 Same as the prior art example shown, the energy absorbing pin 19 passes through the locking base 16 and the portion 19a1 of the shaft portion 19a fits into the axial hole 9a of the spool 9 . Such as figure 2 As shown in (a), the shaft portion 19a of the energy absorbing pin 19 of this example is formed in a linear shape and protrudes perpendicularly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com