Sound deadening system for motorcycle

A technology for motorcycles and mufflers, applied in mufflers, engine components, machines/engines, etc., can solve problems such as burns, easy access, and potential safety hazards, and achieve a safe, versatile, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

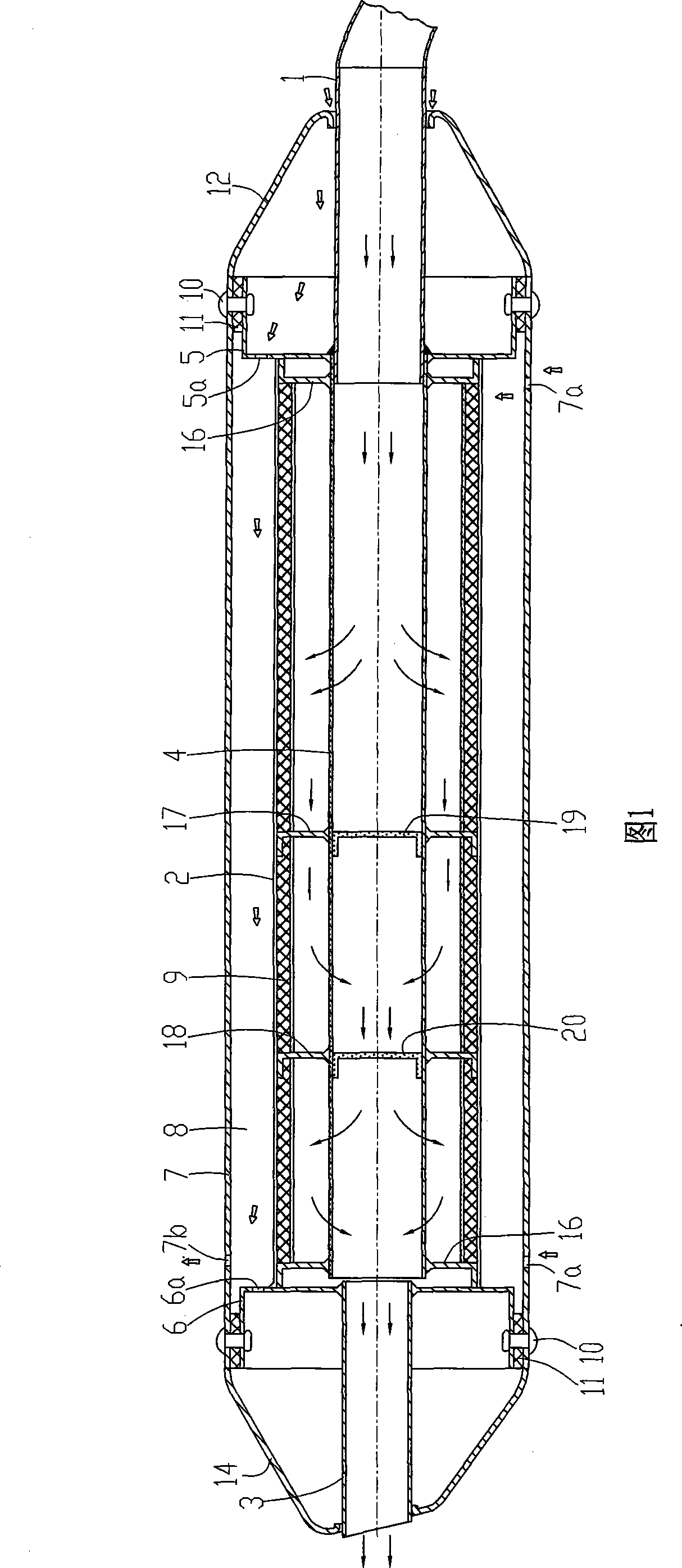

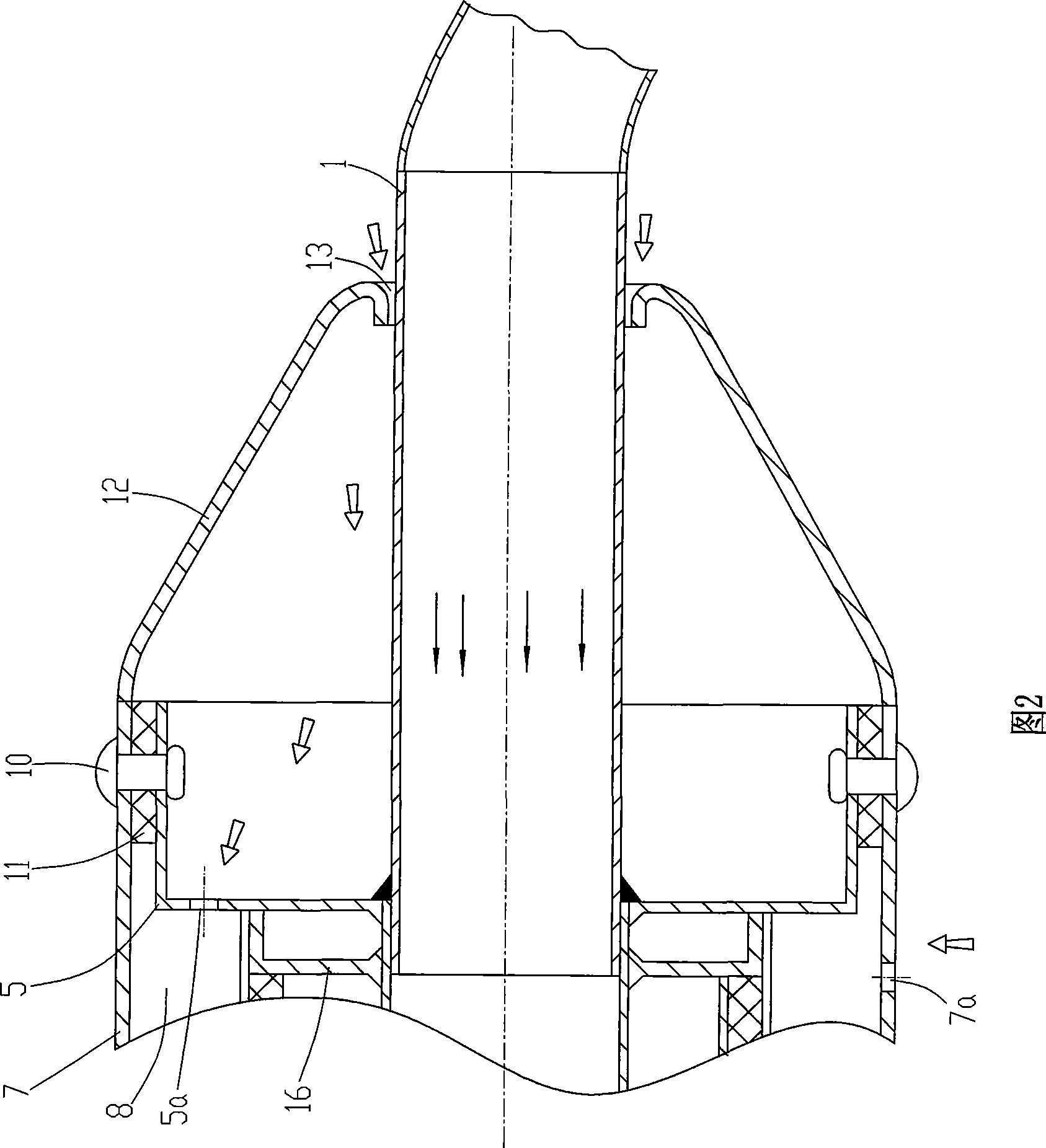

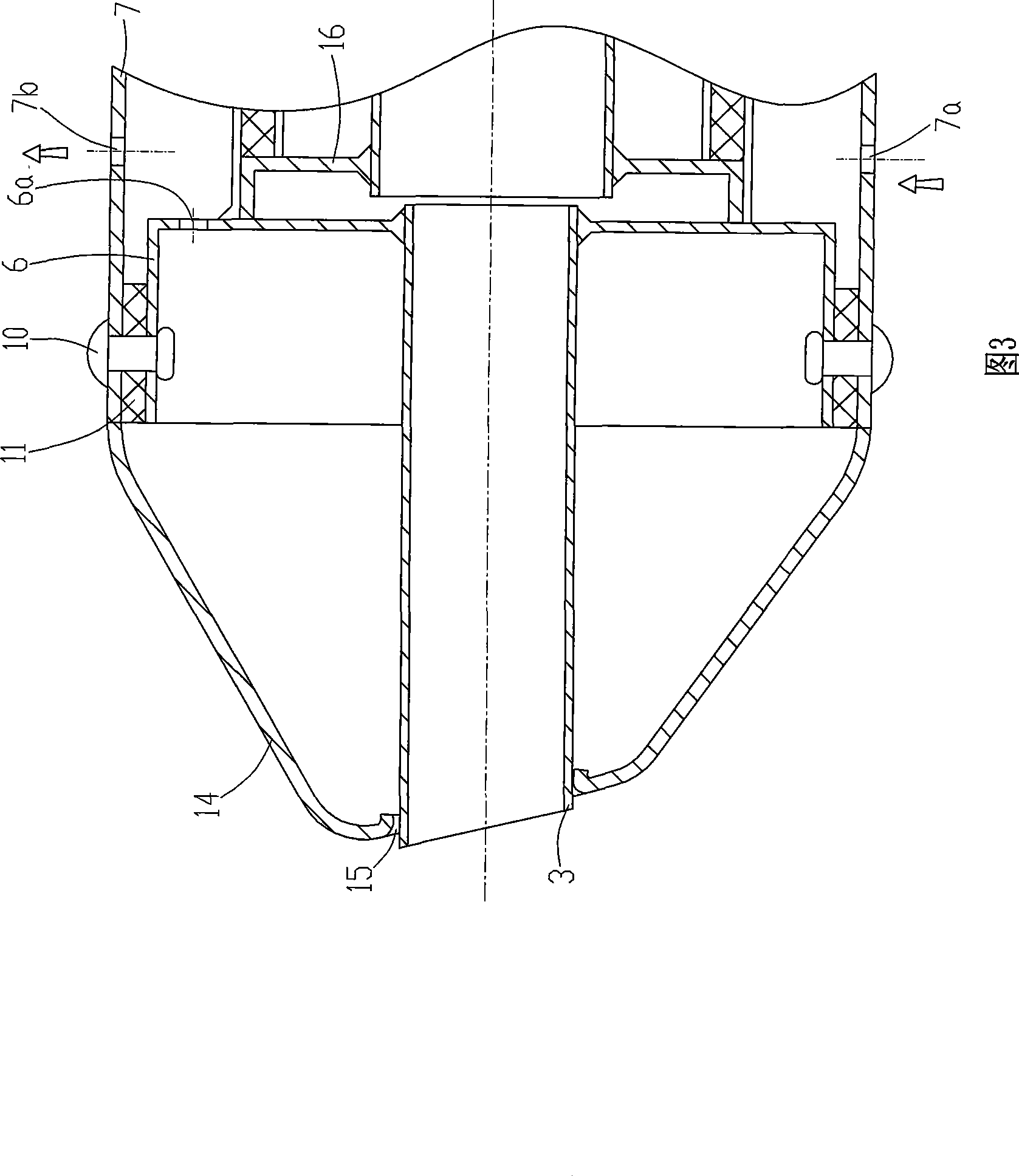

[0017] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0018] As shown in Figure 1, the present invention consists of an intake pipe 1, a muffler 2, a tail pipe 3, a muffler pipe 4, a front nipple 5, a rear nipple 6, an outer cylinder 7, a heat insulator 9, a front decorative cap 12 and The rear decorative cap 14 and other components are formed. The muffler 2 is a straight-through pipe structure, the wall of the muffler 2 is a sandwich structure, and the sandwich is filled with a heat insulating body 9, which can be made of heat insulating cotton or other equivalent heat insulating materials. A muffler tube 4 is arranged in the muffler 2, and the assembly method in the background technology can be used between the muffler tube 4 and the muffler 2 (see FIG. 4). The interior of the body 2 is divided into three chambers by two partition plates, and the two adjacent chambers are communicated through a muffler pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com