Multi-vane cycling air blowing and sucking flow control method for aviation turbofan engine compression system

A turbofan engine and compression system technology, applied in the direction of machines/engines, pump control, mechanical equipment, etc., can solve difficult recycling, affect the life and reliability of high-load fan/compressor blades, reduce the thrust of the whole machine, etc. problem, to achieve the effect of solving the problem of recycling, avoiding the increase of weight and avoiding the increase of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

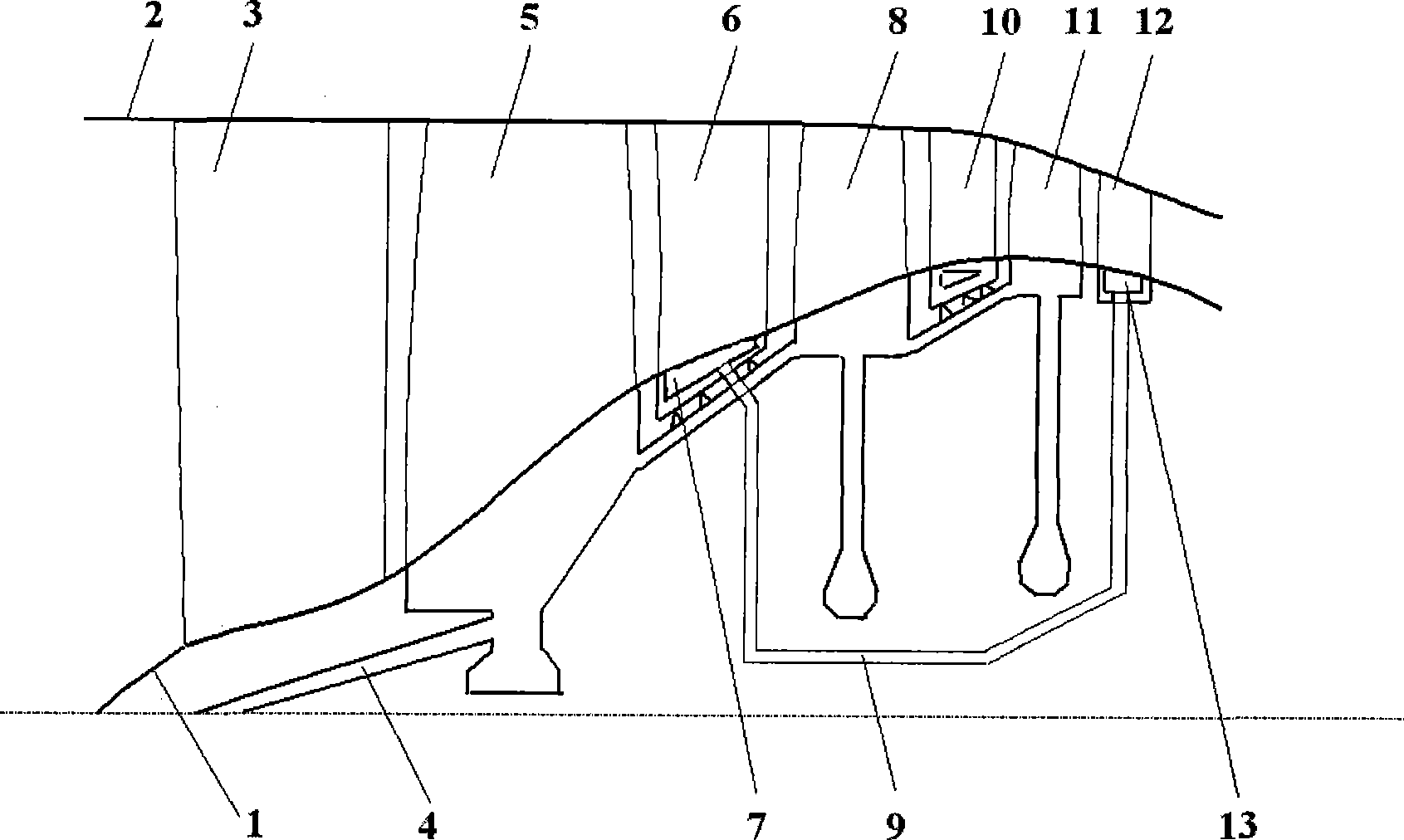

[0030] In order to describe the present invention more clearly, this specific embodiment takes a multi-blade row circulatory active flow control scheme of a turbofan engine fan component as an example, and further illustrates the present invention with reference to the accompanying drawings.

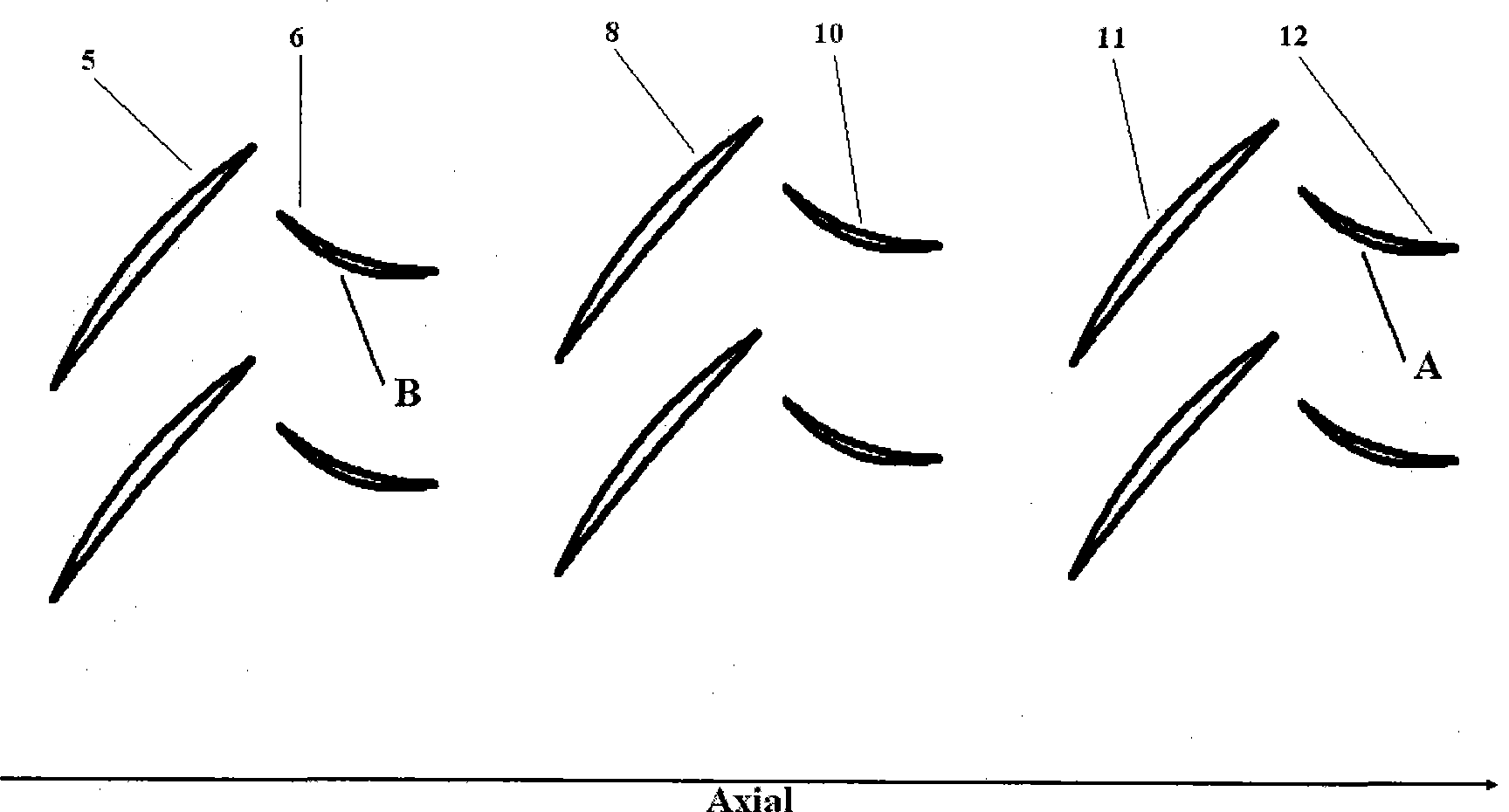

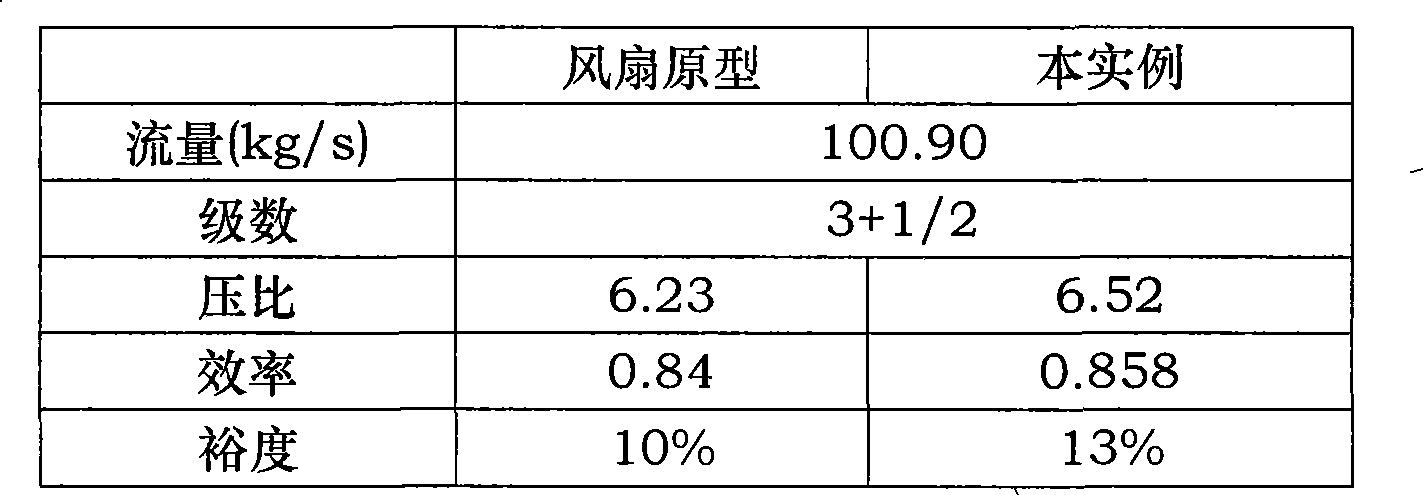

[0031] The example of the present invention is a three-stage fan with inlet guide vanes, the corresponding pressure ratios of each stage are 2.04, 1.91, and 1.60, respectively, and the load coefficients of each stage are 0.28, 0.31, and 0.29, respectively. Flow path geometries for multi-blade rows of fan components that can recirculate active flow control schemes such as figure 1 .

[0032] (1) According to the analysis of the experimental flow field of the computational fluid dynamics numerical simulation of the fan, according to the streamline of the flow field and the position of the three-dimensional separation area, the high-pressure suction blade row and the low-pressure blower bla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap