Optical module mounting construction

An installation structure, optical module technology, applied in the direction of electrostatic, non-printed electrical components connected printed circuits, electrical components, etc., can solve the problem that the optical module provides a large metal plane, can not provide low-impedance electrostatic current discharge channels, etc. problems, to achieve the effect of meeting the requirements of electrostatic protection and overcoming technical prejudice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

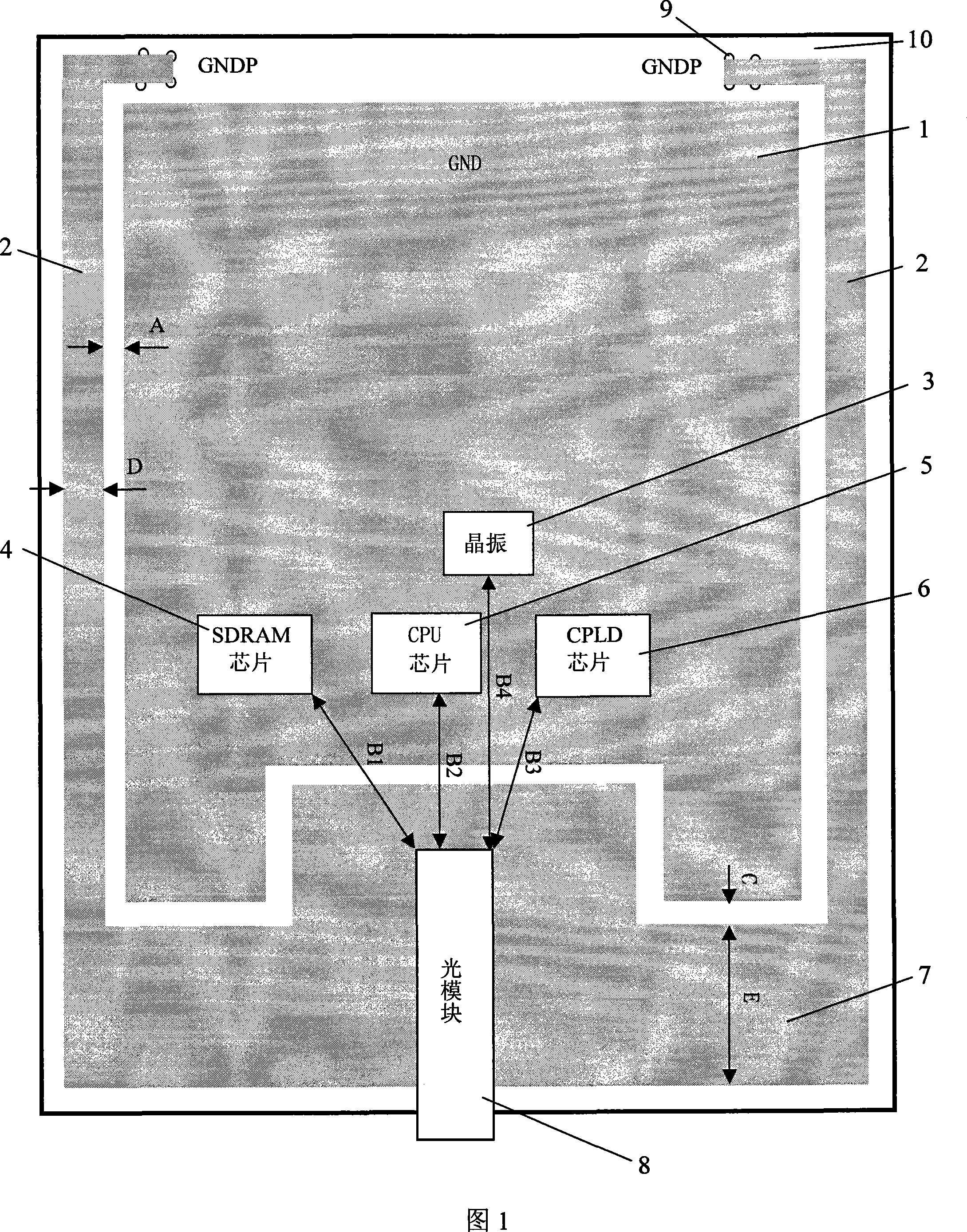

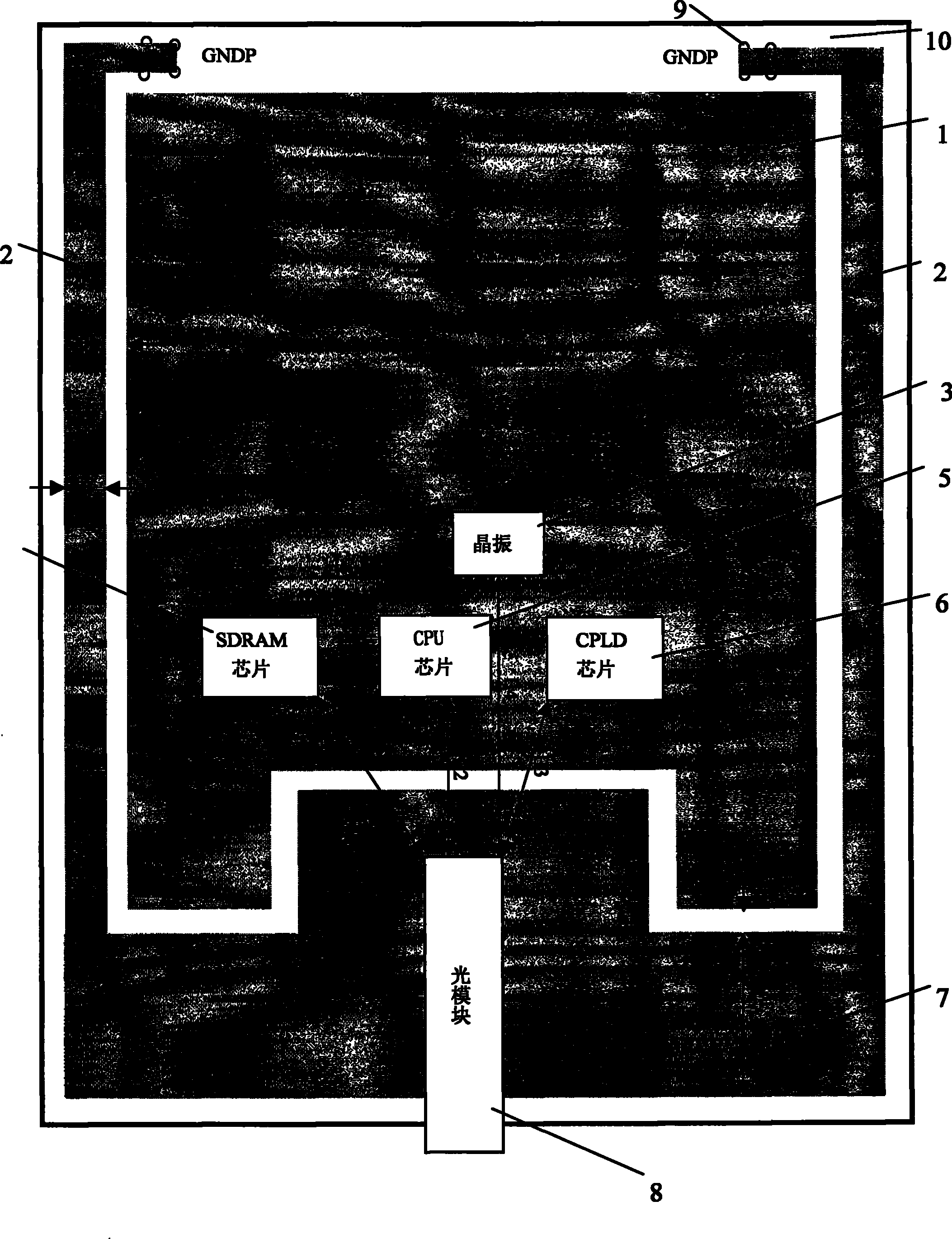

[0023] As shown in Figure 1, the optical module mounting structure of the present invention comprises a PCB board 10 and an optical module 8 installed on the PCB board 10, the layers of the PCB board can be double or multi-layered, in the area where the optical module 8 is located (including Each PCB layer (except the signal layer) on the edge of the circuit board) is designed as an optical module grounding area 7, and a certain number of vias (not shown in the figure) are set in the grounding area 7 along the edge and middle of the optical module grounding area. , the position and spacing of the via holes are adapted to the positions of the pins of the metal shell of the optical module. Usually, the distance between two via holes is about 2 cm. The optical module 8 is electrically connected to the grounds of these layers through the pins of the metal shell. On the side edge of each layer on the PCB board 10 where the optical module 7 is located, the PCB printed line 2 is laid ...

Embodiment 2

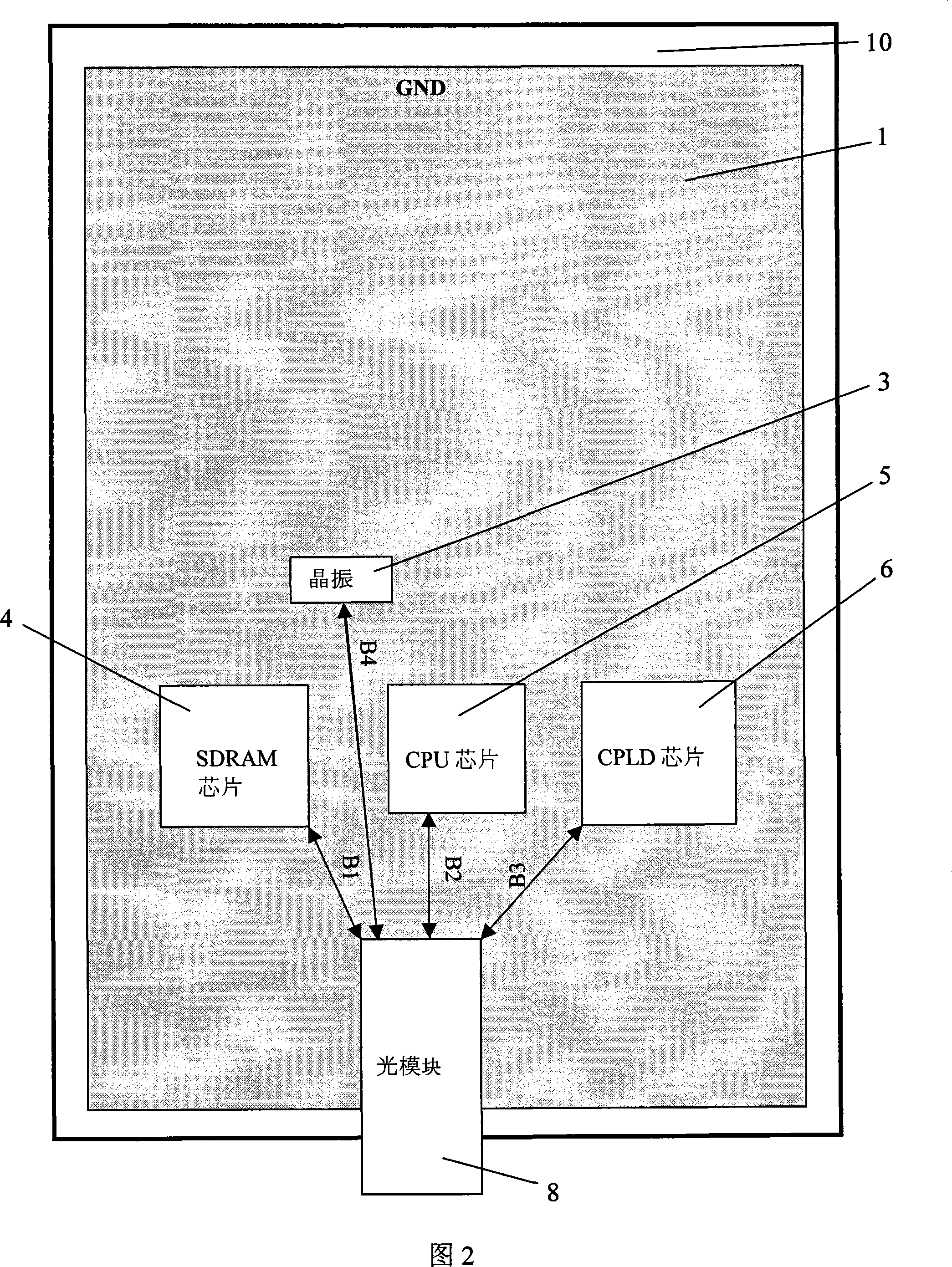

[0029] As shown in Figure 2, in this embodiment, the working ground 1 of the PCB board 10 is directly used as the ground of the shell metal pin of the optical module 8, and the key devices on the PCB board 10 are such as the CPU chip 5, the CPLD chip 6, the SDRAM chip 4, The minimum distance (B1, B2, B3, B4) between the crystal oscillator 3 and the metal housing of the optical module is 3 centimeters, so that the static electricity on the optical module 8 causes fluctuations in the working place to be insufficient to affect the normal operation of the above-mentioned chips. Tests have shown that it is more reasonable for the minimum distance to be 3 cm to 5 cm.

[0030] This embodiment is considered to be unreasonable and not allowed in traditional design. But for the optical port, there is no problem of lightning protection or EFT interference, so it is feasible to use the working ground on the circuit board as the static discharge ground of the optical module. Through the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com