Strip-steel flatness measuring method based on single-step phase-shift method

A measurement method and flatness technology, applied in the field of steel rolling, can solve the problems of uncertain error of strip steel fiber length, unsuitable for moving object measurement, large amount of data collection, etc., to avoid vibration and swing of strip steel, simple structure, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

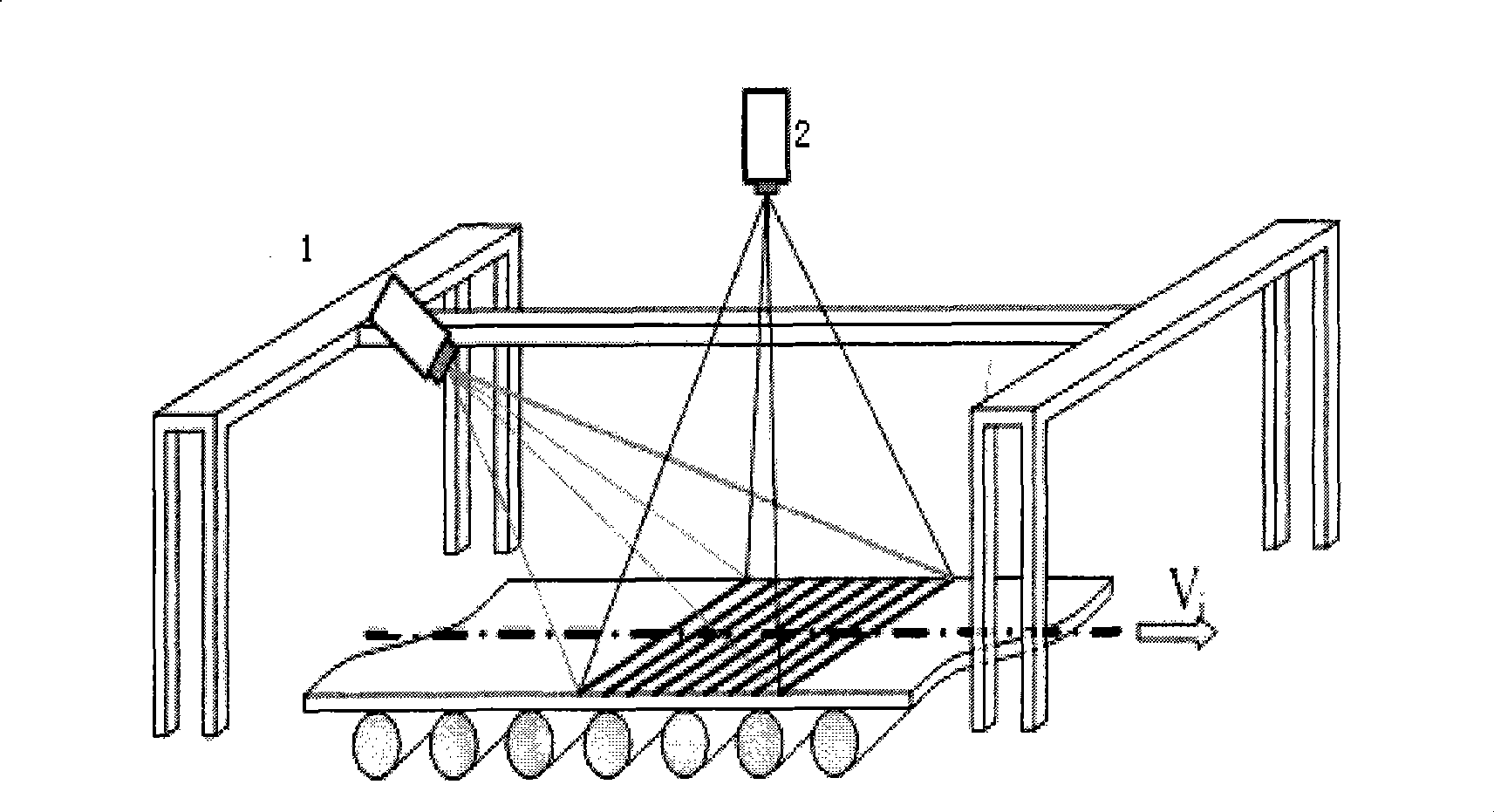

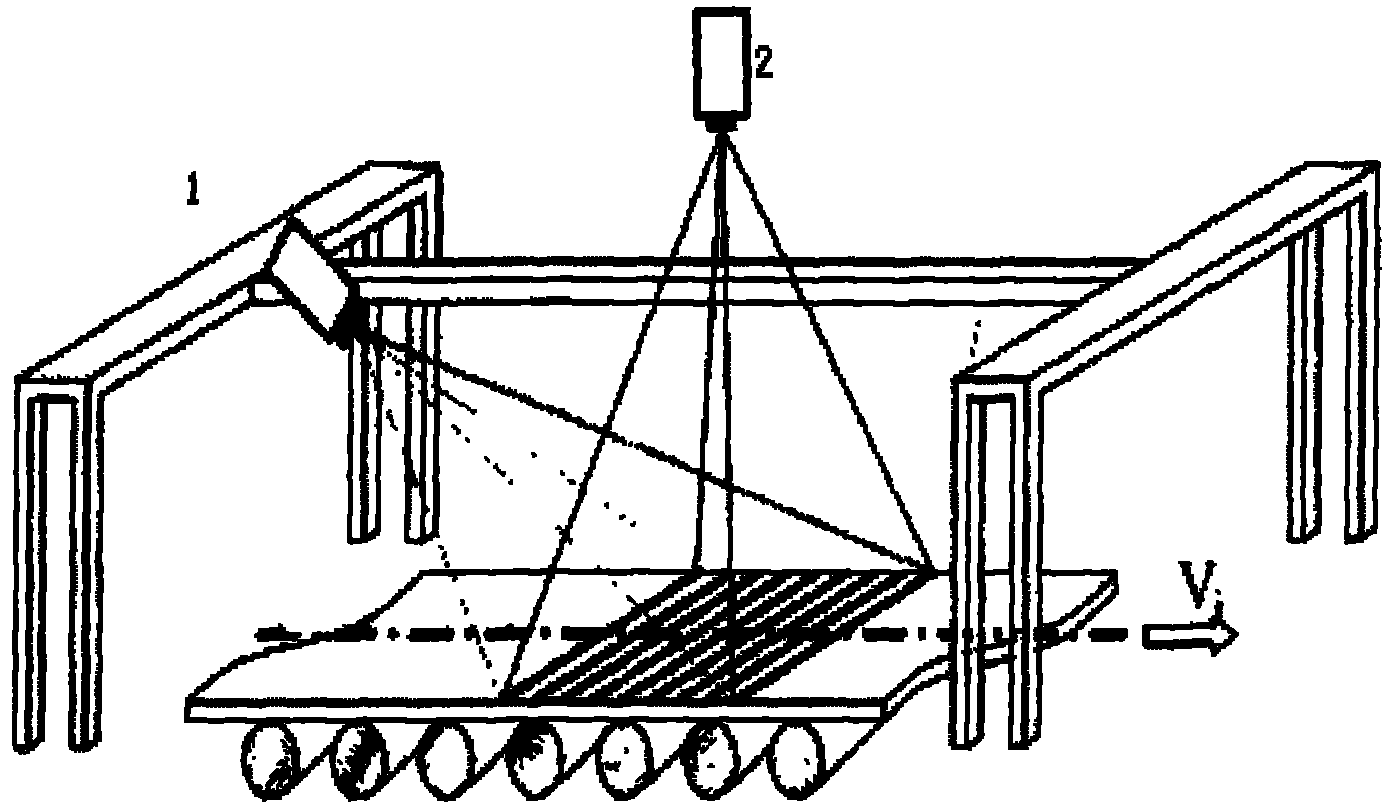

[0031] exist figure 1 In the above, the DLP (1) is installed obliquely above the center side of the steel strip, and the angle and range of projection can be properly adjusted according to the actual situation. Usually, the incident angle of the optical axis of the DLP (1) and the projected light section is more suitable in the range of 20°-50°. The installation height of the area array CCD camera (2) is the same as that of the DLP (1), and the optical axis is perpendicular to the surface of the steel strip. A filter is installed in front of the area array CCD camera (2) to filter out impurity light sources (such as hot-rolled strips) near-infrared light).

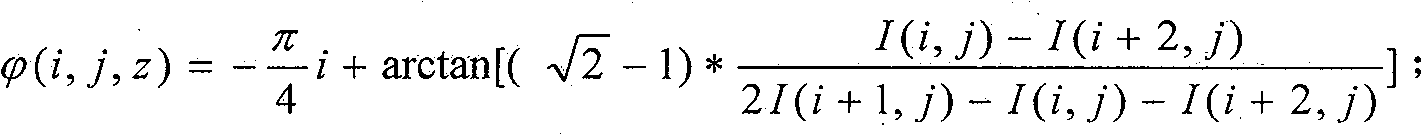

[0032] The DLP projector obliquely projects the sinusoidal grating fringe (gray value distribution according to the sinusoidal law) image compiled by the software onto the strip surface, and the deformed fringe image is taken by the area array CCD camera vertically installed directly above the center side of the strip, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com