Tension control system of plastic packaging film production line

A technology of tension control and packaging film, which is applied in the field of plastic extrusion film blowing machine equipment, can solve the problems of excessive stretching, unwinding, and low degree of automation, and achieve the effect of improving product quality and precision, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

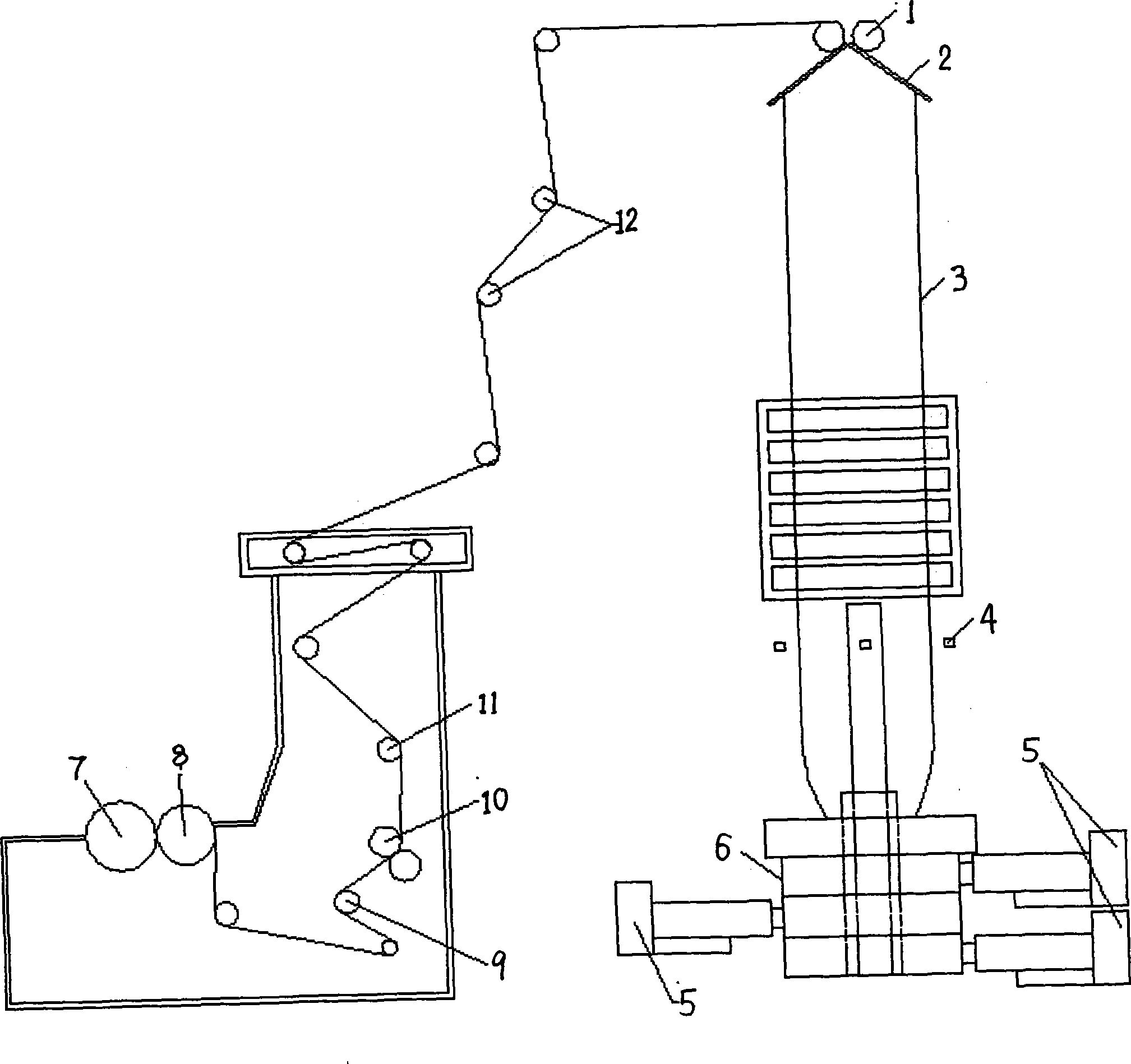

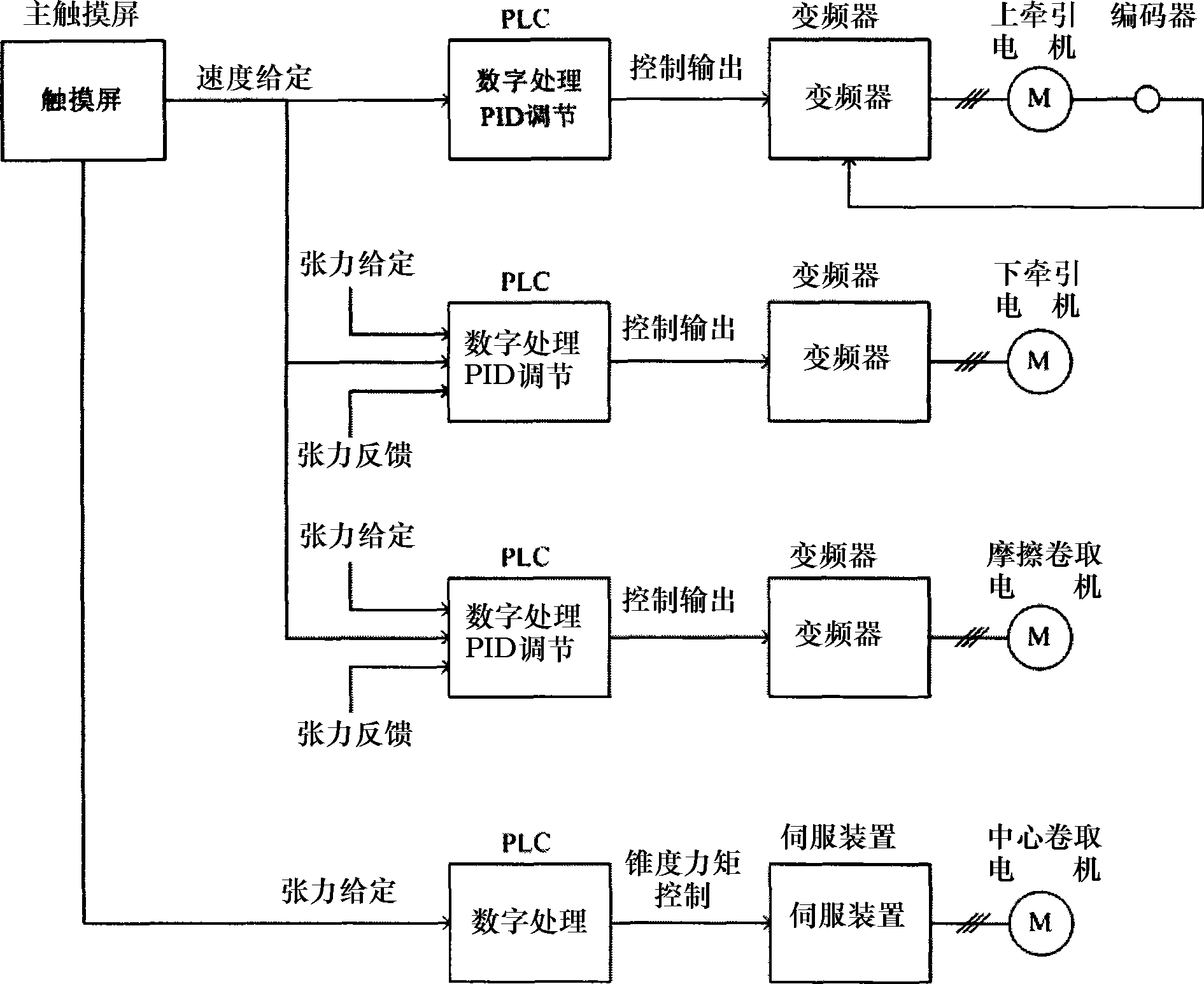

[0013] Such as figure 1 The tension control system of the plastic packaging film production line shown is composed of three tension sections connected in series, one tension section is between the upper traction 1 and the lower traction 10, one tension section is between the lower traction 10 and the friction coil 8, and the friction coil 8 to The center coiling 7 is another tension section, the upper traction motor, the lower traction motor and the friction coiling motor are respectively given the speed given value, and the lower traction motor, the friction coiling motor and the center coiling motor are respectively given the tension given value , the given value and feedback value of each tension section are sent to the controller for PID calculation, and the controller sends control signals to implement the control of different tension requirements of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com