Composite incubation material

A technology of thermal insulation and composite materials, which is applied in the direction of synthetic resin layered products, laminations, and layered products, etc. It can solve the problems of short service life, performance degradation, and easy water absorption of inorganic fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

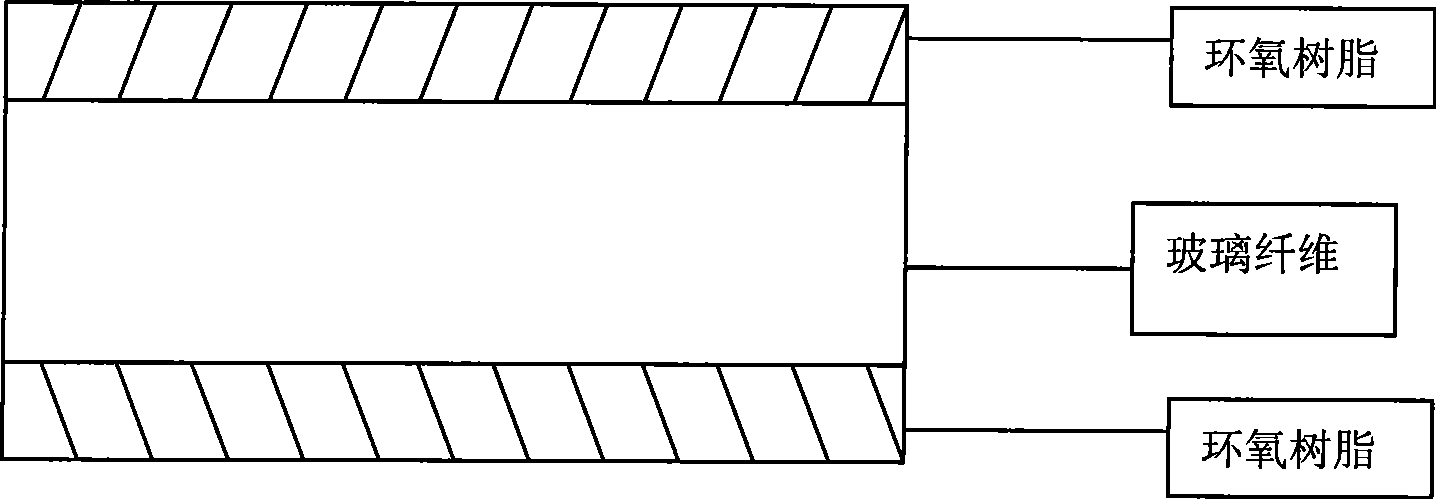

Image

Examples

Embodiment Construction

[0007] (1) Choose 80-800 grams of glass fiber cotton with a diameter of 3-8 μm, preform it into a plate shape, bake it at 120 degrees for 0.5-4 hours, and then let it cool to room temperature in a desiccator.

[0008] (2) Punch 10*10cm of fiber cotton, and put 5-50 grams of calcium oxide particles into the holes.

[0009] (3) Put the inorganic fiber cotton into the injection mold, inject epoxy resin mixed with curing agent, heat and cure at 60-100 degrees for 0.5-2 hours.

[0010] Product see attached picture

[0011] Of course, those of ordinary skill in the technical field should recognize that the above-mentioned embodiments are only used to illustrate the present invention, rather than to limit the present invention. All will fall within the scope of the claims of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com