Glass hot transfer foil and preparation method thereof

A thermal transfer layer, thermal transfer technology, applied in the direction of copy/marking method, printing, temperature recording method, etc., to achieve the effect of clear and beautiful pattern aesthetics, reasonable color matching, bright colors, weather resistance, long-lasting discoloration and fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

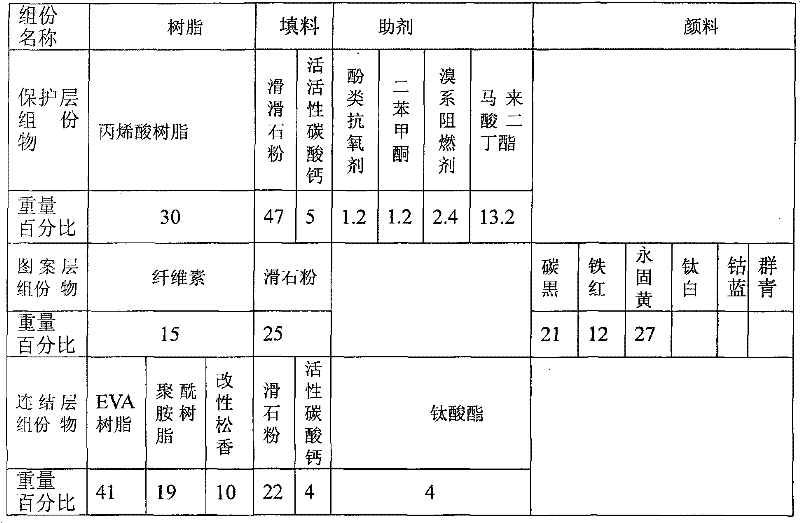

Embodiment 1

[0033]

[0034] In embodiment 1, the tape base is selected 23 μm thick high-strength polyester film, and the solvent of each raw material of the protective layer in the transfer layer is toluene and butyl ester mixed in a weight ratio of 2:1, and the coating thickness is 6 μm; The solvent of each raw material of the layer is toluene, and the coating thickness is 4 μm; the solvent of the raw materials of the linking layer is xylene and isopropanol mixed in a weight ratio of 2:1, the coating thickness is 4 μm, and the total thickness of the transfer layer is 14 μm.

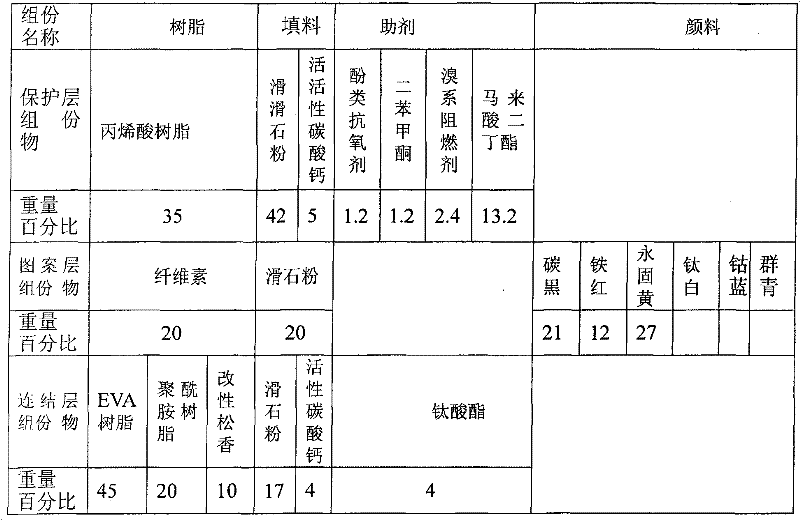

Embodiment 2

[0036]

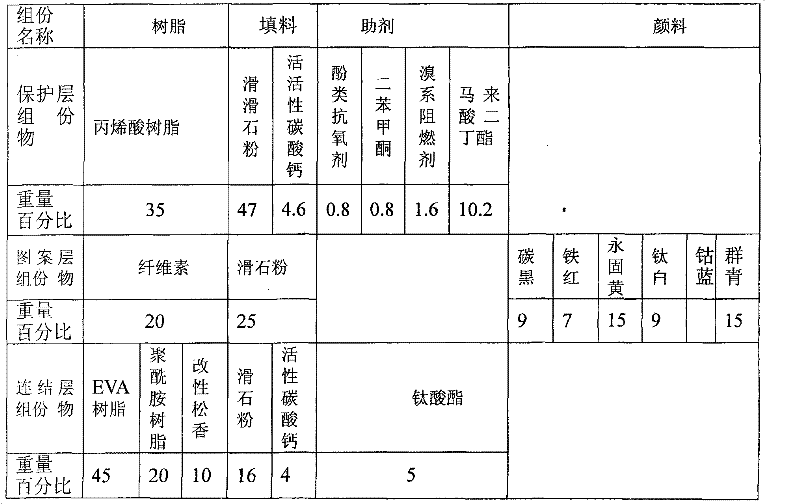

Embodiment 3

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com