Constant tension center coiling control system

A control system, constant tension technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

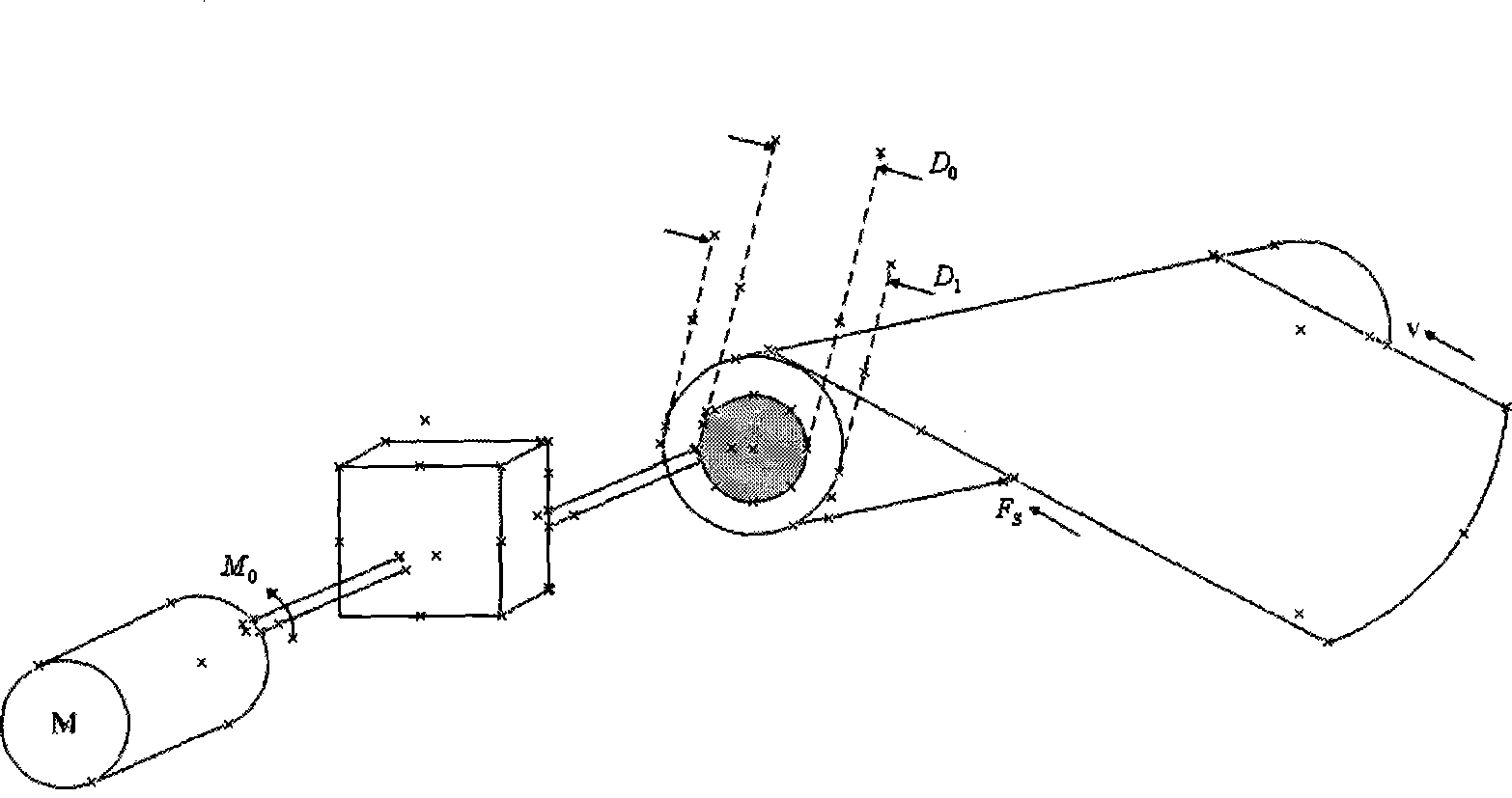

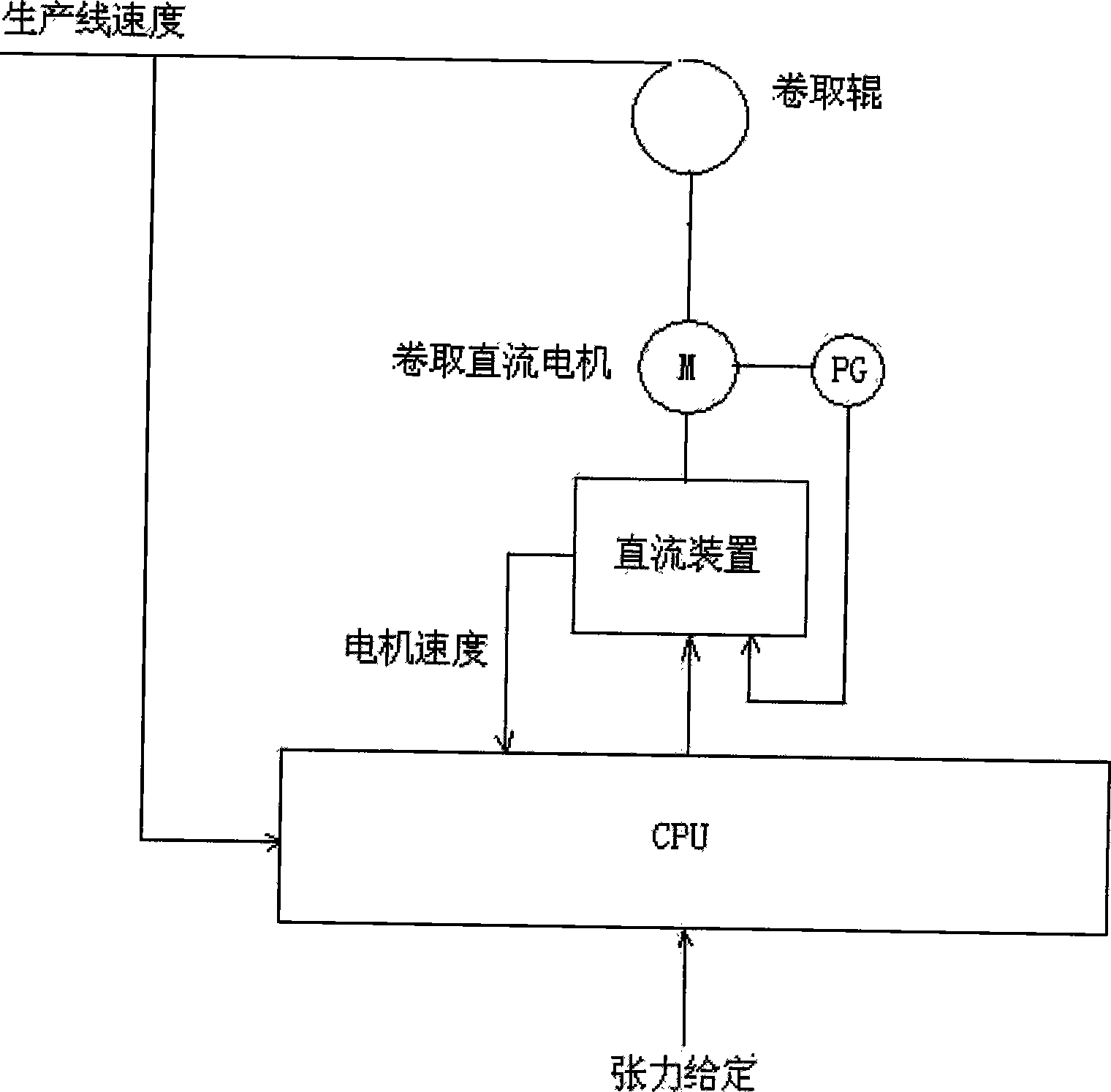

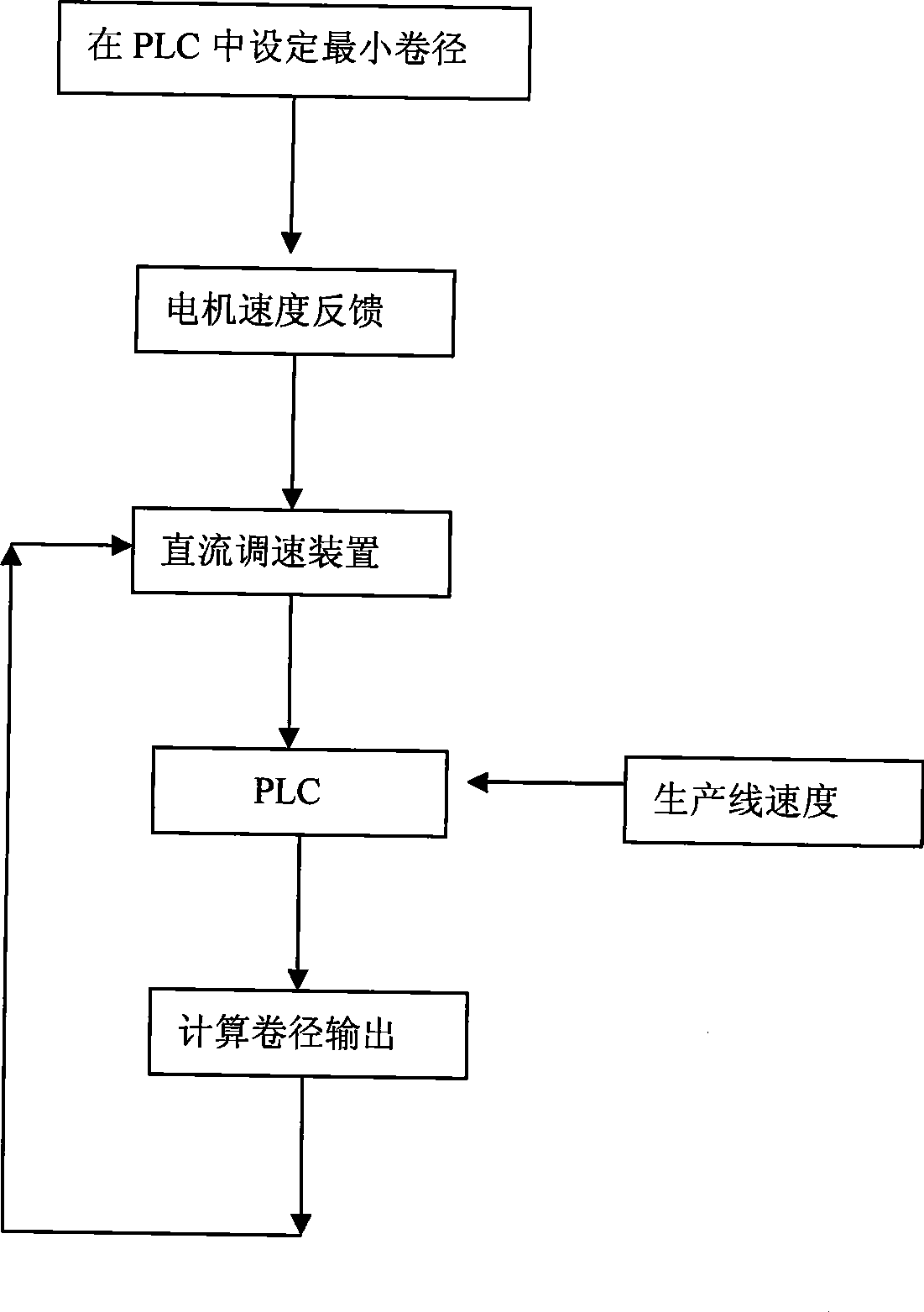

[0024] Constant tension center coiling control system, such as figure 1 , 2 As shown, a controller is installed between the motor and the take-up roller, such as image 3 As shown, set the minimum winding diameter value in the CPU of the controller (PLC), start the motor, the motor speed is equipped with PG detection to collect the speed detection signal in real time, and transmit the speed signal to the DC speed control device, through the DC speed control device Feedback to the controller CPU, the real-time production line speed of the coiling roller is transmitted to the CPU through detection, the controller receives the production line speed, and the software system calculates according to the following formula and outputs the coil diameter value to the DC speed control device to adjust the coiling center.

[0025] Principle formula of the present invention:

[0026] (1) Maximum load torque [NM]: M 0 = M 1 +M 固

[0027] (2) Maximum control torque [NM]: M 1 =F S(max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com