Water-saving and emission-reducing wet method phosphoric acid manufacture process

A production process, a technology for wet-process phosphoric acid, applied in the field of phosphoric acid, can solve the problems of difficulty in achieving process water balance, increased sewage discharge, decreased production capacity, etc., so as to improve the production capacity of phosphoric acid, reduce the amount of water discharged, and reduce labor consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

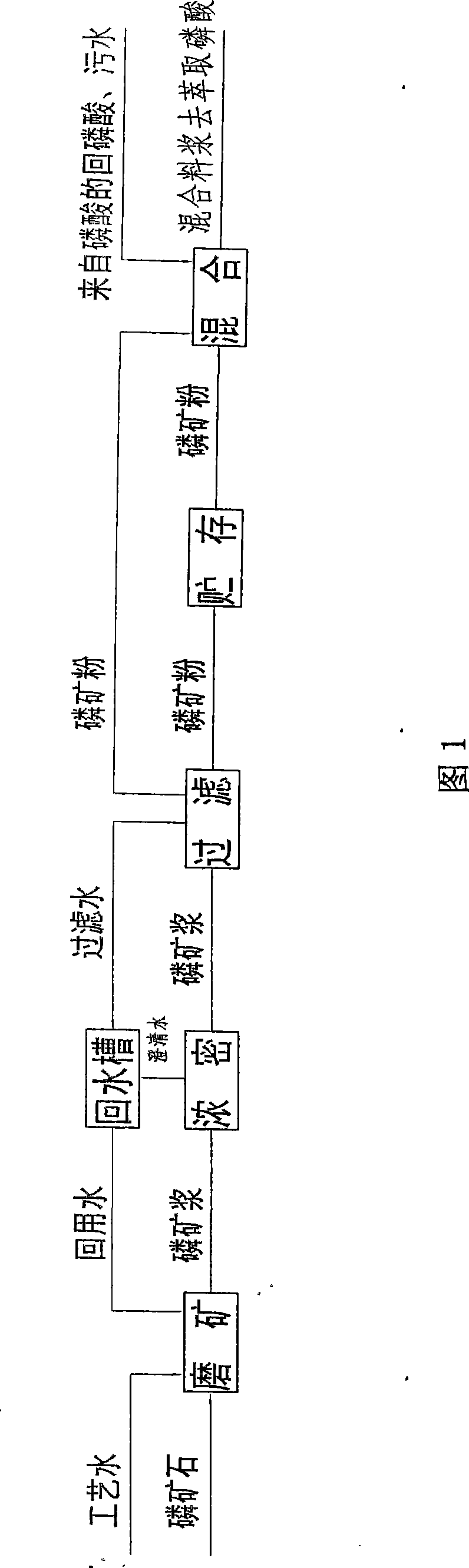

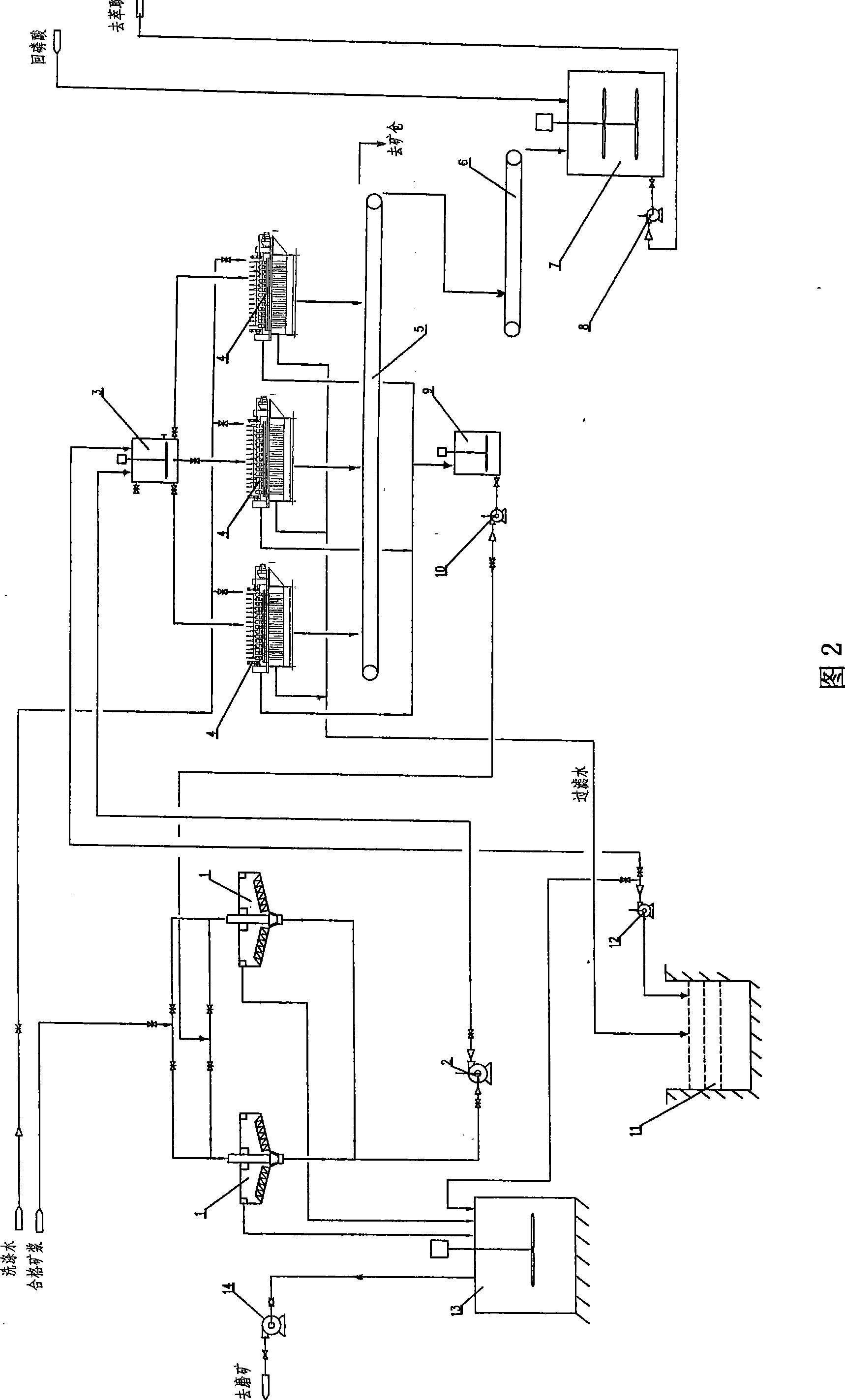

[0011] Example 1 The post-grinding system process of the wet-process phosphoric acid production process as shown in the accompanying drawing, the slurry formed after the phosphate rock and water are ground by a wet mill is separated by a cyclone separator, and the unqualified coarse particles are separated from the bottom of the cyclone Discharge and re-enter the mill for grinding. The qualified pulp with 50% water content discharged from the top of the cyclone enters the high-efficiency thickener 1 for thickening, and then sends it to the high tank 3 of the filter 4 with the pulp delivery pump 2, and puts it down to the filter 4 for further processing. Filtration; part of the filtered mineral powder is sent to the mineral powder storage hopper by the belt conveyor 5, 6, and then transported to the metering screw by the disc feeder, and added to the mixing tank 7 after metering; the other part of the mineral powder is sent to the mineral powder Storage in the silo, when the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com