Method for preparing sludge active carbon by using sludge and sludge active carbon

A sludge activated carbon and sludge technology, applied in the field of sludge activated carbon, can solve the problems of polluting the environment and occupying land, and achieve the effects of fast adsorption speed, outstanding adsorption balance ability, and abundant transition pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

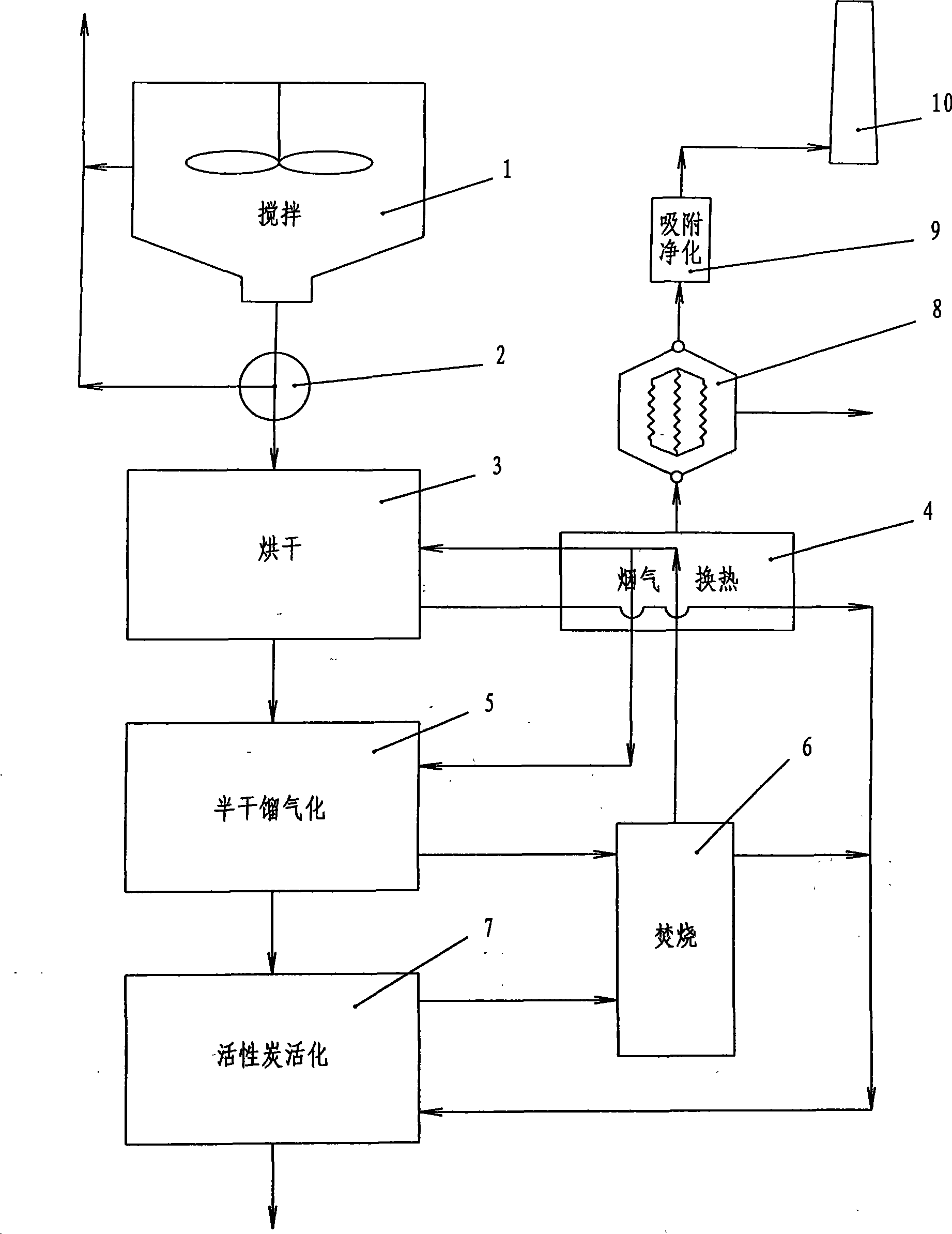

[0020] The method for preparing sludge activated carbon by utilizing sludge of the present invention comprises the following steps:

[0021] (1) adding 50 or 100 parts by weight of flocculant PAM and 2 or 5 or 8 or 10 parts by weight of heavy metal chelating agent according to the sludge of 1,000,000 parts by weight of purified water treatment plant and / or sewage water treatment plant to obtain sludge ingredients;

[0022] (2) the sludge batching obtained in step (1) is placed in a stirring device and stirred, and then the stirred sludge batching is placed in a concentration and dewatering device for dehydration, and the water content of the sludge batching after the concentration and dehydration is 75% % or 85%;

[0023] (3) placing the dehydrated sludge ingredients obtained in step (2) in a drying device for drying, and the drying temperature is 60°C or 70°C or 80°C or 90°C or 110°C or 120°C. The moisture content of the mud ingredients is 20% or 30%;

[0024] (4) placing ...

Embodiment 2

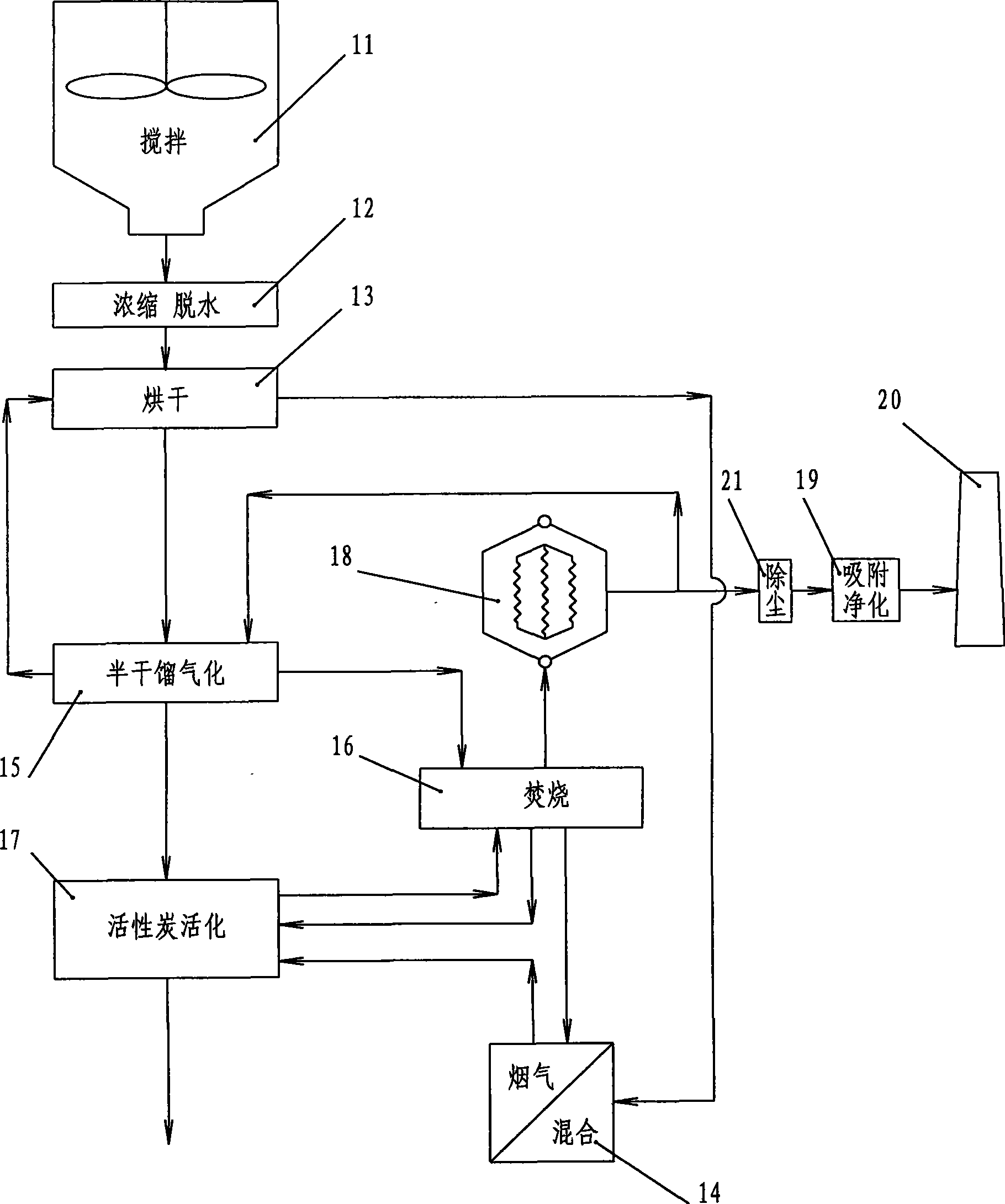

[0028] The method for preparing sludge activated carbon by utilizing sludge of the present invention comprises the following steps:

[0029] (1) add 60 or 90 parts by weight of flocculant PAM and 3 or 4 or 9 or 10 parts by weight of heavy metal chelating agent according to the sludge of 1,000,000 parts by weight of purified water treatment plant and / or sewage water treatment plant to obtain sludge ingredients;

[0030] (2) the sludge batching obtained in step (1) is placed in a stirring device and stirred, and then the stirred sludge batching is placed in a concentration and dewatering device for dehydration, and the water content of the sludge batching after the concentration and dehydration is 78% % or 82%;

[0031] (3) placing the dehydrated sludge ingredients obtained in step (2) in a drying device for drying, and the drying temperature is 65°C or 75°C or 85°C or 95°C or 115°C or 120°C. The moisture content of the mud ingredients is 25% or 28%;

[0032] (4) placing the ...

Embodiment 3

[0036] The method for preparing sludge activated carbon by utilizing sludge of the present invention comprises the following steps:

[0037] (1) add 70 or 80 parts by weight of flocculant PAM and 2 or 5 or 8 or 10 parts by weight of heavy metal chelating agent according to the sludge of 1,000,000 parts by weight of purified water treatment plant and / or sewage water treatment plant to obtain sludge ingredients;

[0038] (2) placing the sludge batching obtained in step (1) in a stirring device and stirring, then placing the stirred sludge batching in a concentration and dewatering device for dehydration, and the water content of the sludge batching after the concentration and dehydration is 80% % or 84%;

[0039] (3) placing the dehydrated sludge ingredients obtained in step (2) in a drying device for drying, and the drying temperature is 60°C or 70°C or 80°C or 90°C or 110°C or 120°C. The moisture content of the mud ingredients is 22% or 27%;

[0040](4) Place the dried slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com