Recombinant acetone-butanol clostridium and construction method and use thereof

A technology of Clostridium acetobutylicum and ATP synthase, which is applied in the direction of recombinant DNA technology, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of not being able to increase the production of butanol, and achieve the improvement of fermentation production rate and enhanced The effect of metabolic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

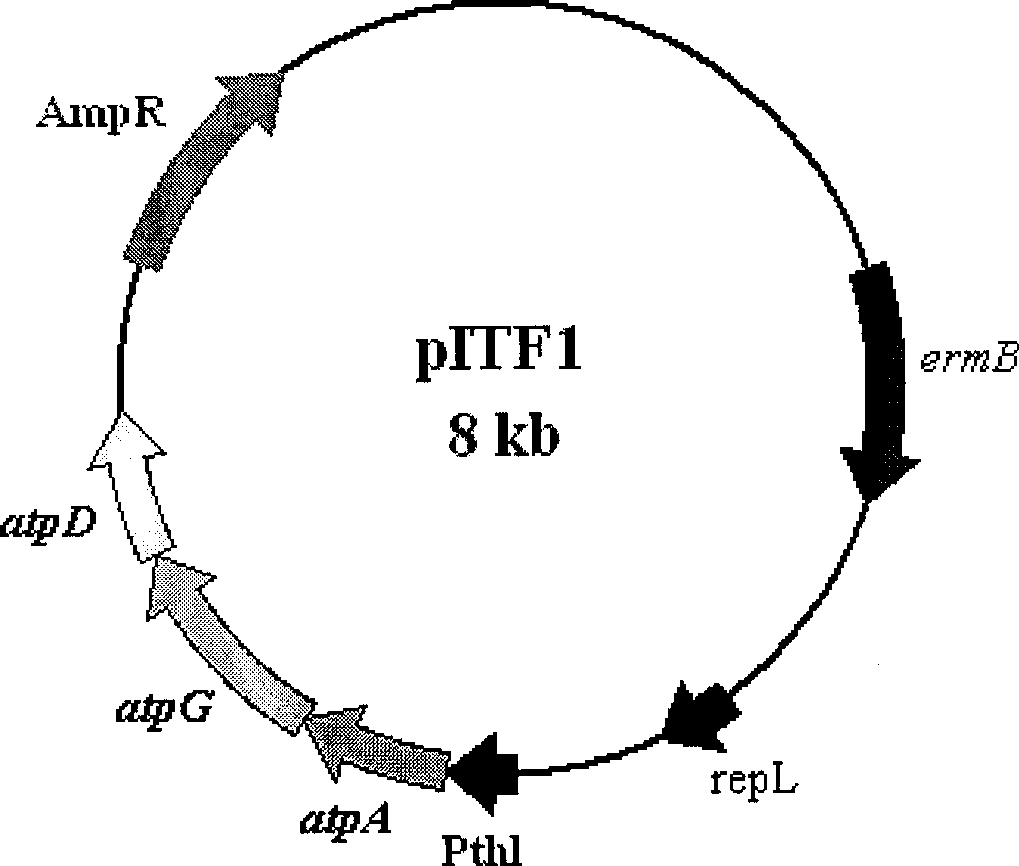

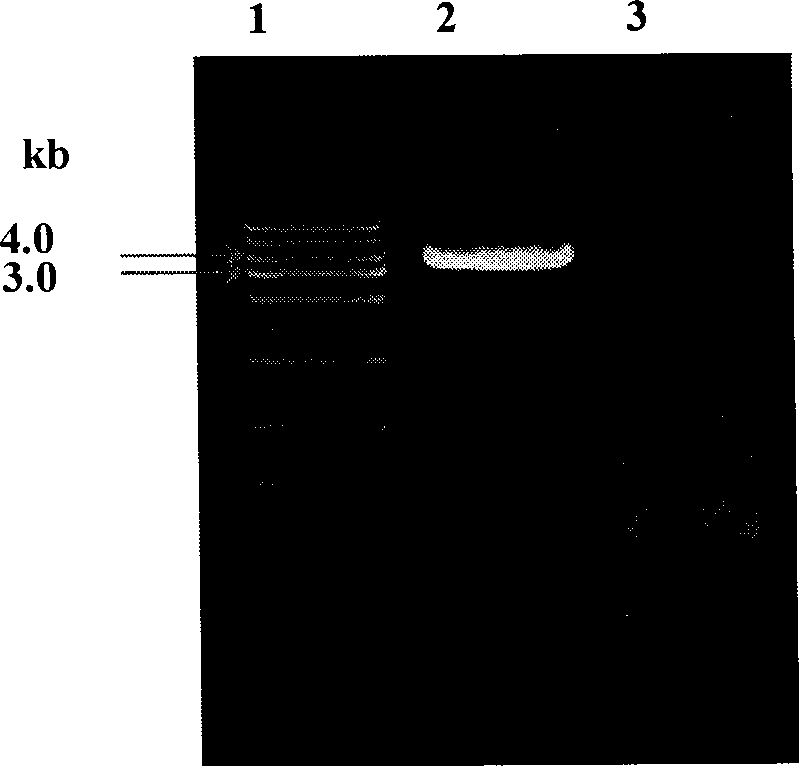

[0038] Embodiment 1, construct the Clostridium acetobutylicum expressing the hydrophilic part of FoF1 type ATP synthase

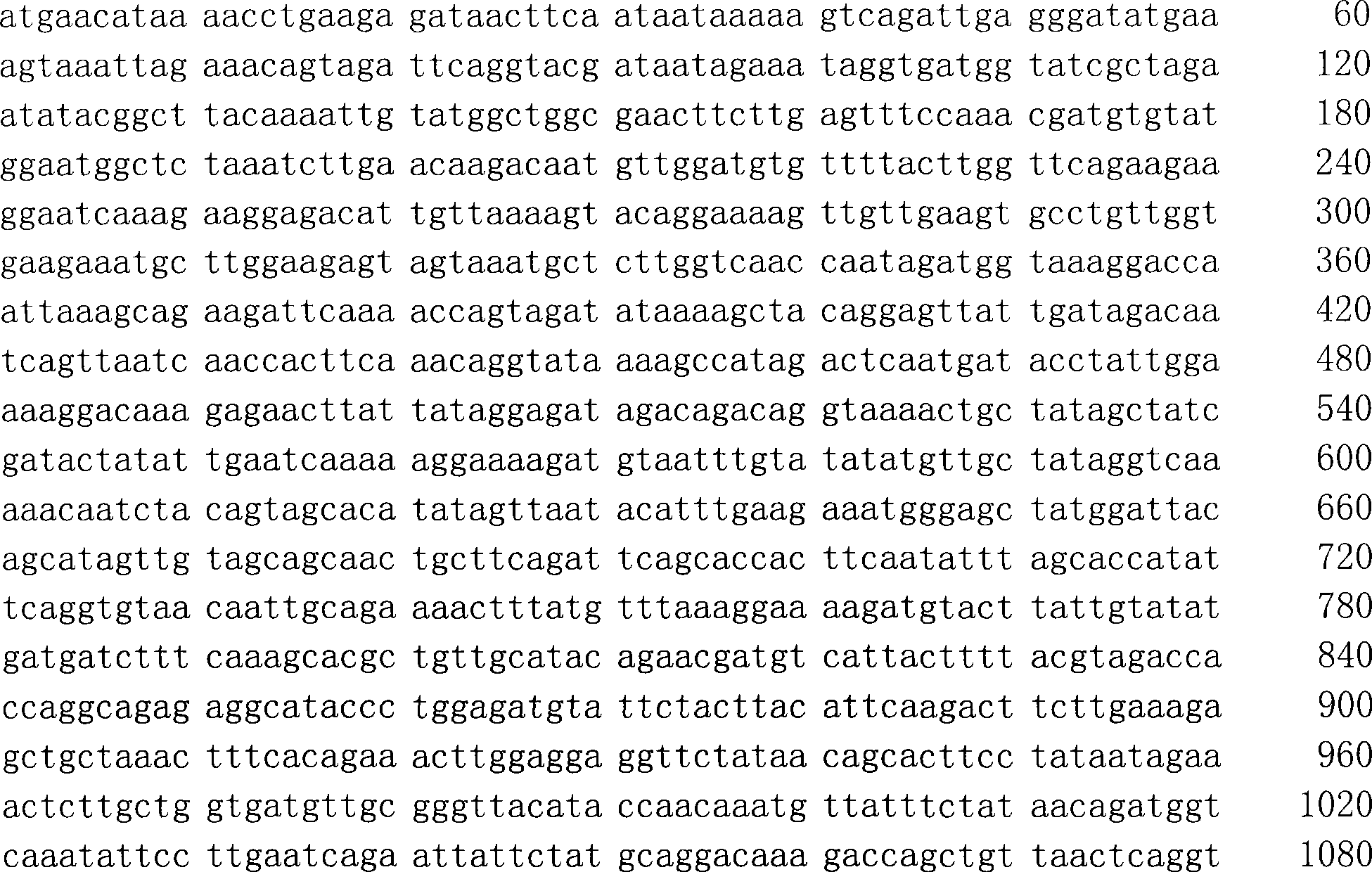

[0039] Using lysozyme, SDS and other reagents to destroy the conventional bacterial genome extraction method of the cell wall, extract the genomic DNA of Clostridium acetobutylicum (Clostridium acetobutylicum) ATCC 824 (American Type Culture Collection, U.S. Patent US7432090), according to the conventional PCR method, use The high-fidelity DNA polymerase Pfu amplifies the thiolase promoter region (Pthl) and the atpAGD gene coding region (the three genes atpA, atpG, and atpD are in one operon), and the primers are shown in Table 1.

[0040] Table 2. Nucleotide sequences of primers

[0041] Primer name sequence Restriction sites Pthl-F agt gtcgac tatattgataaaaataataatatagtggg Sal I

[0042] Pthl-R cgt ggatcc ttctttcattctaactaacctcc Bam H I at pAGD-F gtcc ggatcc atgaacataaaacctgaagagataacttcaataataaaaag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com