Fermentation production method of validacin

A technology of effectivemycin and production method, applied in the directions of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of decreased intracellular protein content, long fermentation period, decreased protein amount, etc., and shortened the fermentation period. , the effect of increasing comprehensive benefits and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Experimental materials:

[0024] Strains used: Streptomyces hygroscopicus var.jingganggensis 5008

[0025] 2. Experimental steps:

[0026] (1) Strain activation and plate culture

[0027] Take the frozen glycerol spore suspension and spread it evenly on the YMS plate densely. After inoculation, place it at 30°C for 5-6 days to produce cyan or gray spores. Add 3-4ml of sterile water to the spore-forming plate, and gently scrape the spores covered on the surface of the plate with a cotton swab to suspend them in sterile water.

[0028] (2) Seed cultivation

[0029] The stainless steel spring is curled into a ring shape, placed in a 250ml Erlenmeyer flask, then filled with 50ml seed culture medium, and sterilized. After the culture medium is cooled, draw 10 l of the spore suspension and add it to the shaker flask for inoculation. After inoculation, the shake flasks were cultured at 28°C, 30°C, and 35°C at 220 rpm for 20 hours. Three parallel experiments were set ...

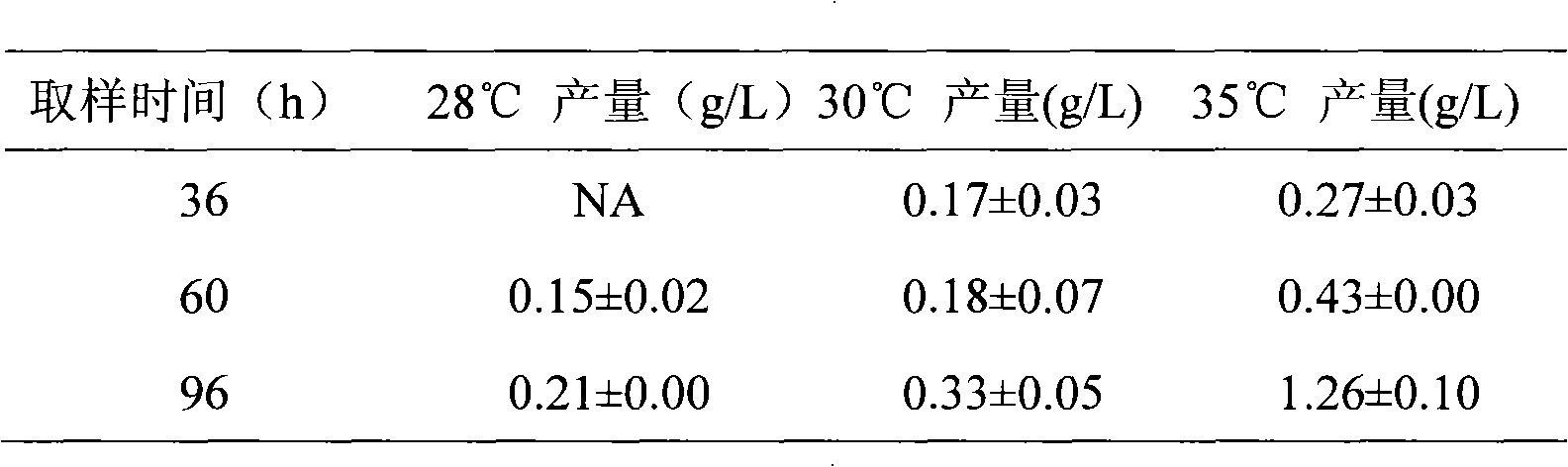

Embodiment 2

[0040] 35°C, 37°C, and 40°C were selected for the fermentation test. The implementation steps and results are as follows:

[0041] 1. the bacterial classification that adopts: with embodiment 1

[0042] 2. Strain activation and plate culture method: with embodiment 1

[0043] 3. Seed culture:

[0044]After inoculation, the shake flasks were cultured at 35° C., 37° C., and 40° C. for 20 hours. All the other are with embodiment 1.

[0045] 4. Fermentation culture

[0046] The obtained seeds were cultivated at 35°C, 37°C, and 40°C, inserted into the fermentation medium, and placed in the corresponding temperature conditions of 35°C, 37°C, and 40°C, respectively, and cultured at 220 rpm. Three shake flasks were taken at 84 hours for various assays. All the other method steps are the same as in Example 1.

[0047] 4. Detection of fermentation process

[0048] (1) Detect effective mycin yield, method is the same as embodiment 1 (results are shown in Table 2).

[0049] Table...

Embodiment 3

[0060] The fermentation temperatures 37°C, 40°C, and 42°C, which were higher than the temperature response threshold, were selected for fermentation experiments. The implementation steps and results are as follows:

[0061] 1. the bacterial classification that adopts: with embodiment 1

[0062] 2. Strain activation and plate culture method: with embodiment 1

[0063] 3. Seed culture

[0064] After inoculation, the shake flasks were cultured at 37° C., 40° C., and 42° C. for 20 hours. All the other are with embodiment 1.

[0065] 4. Fermentation culture

[0066] The obtained seeds were cultivated at 37°C, 40°C, and 42°C, inserted into the fermentation medium, and placed in the corresponding temperature conditions of 37°C, 40°C, and 42°C, respectively, and cultured at 220 rpm. At 12, 24, 36, 60, and 96 hours, three shake flasks were taken for various tests, and the fermentation was completed after 36 hours at 42°C. All the other method steps are the same as in Example 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com