Fe-Co base bulk amorphous alloy and preparation method thereof

An amorphous alloy and bulk technology, which is applied in the field of Fe-Co-based bulk amorphous alloy and its preparation, and achieves the effects of overcoming complicated processing technology, good amorphous forming ability and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition (atomic percentage) of the iron-cobalt-based bulk amorphous alloy with soft magnetic properties in this embodiment is: 33% Fe, 33% Co, 3% Zr, 4% Nd, 5% Nb, and 22% B. The preparation process and steps are as follows: prepare 10 grams of Fe, Co, Zr, Nd, Nb and FeB alloys of industrially pure metals according to the composition of the Fe-Co-based bulk amorphous alloy of this embodiment, and then use vacuum non-consumable arc The furnace is smelted under the protection of argon, and the smelting current density is 150A / cm 2 , the smelted alloy was turned over and smelted 4 times to obtain the master alloy; after remelting the master alloy, it was poured by copper mold negative pressure suction casting method to obtain a bulk amorphous alloy with a size of 0.8mm×10mm×80mm.

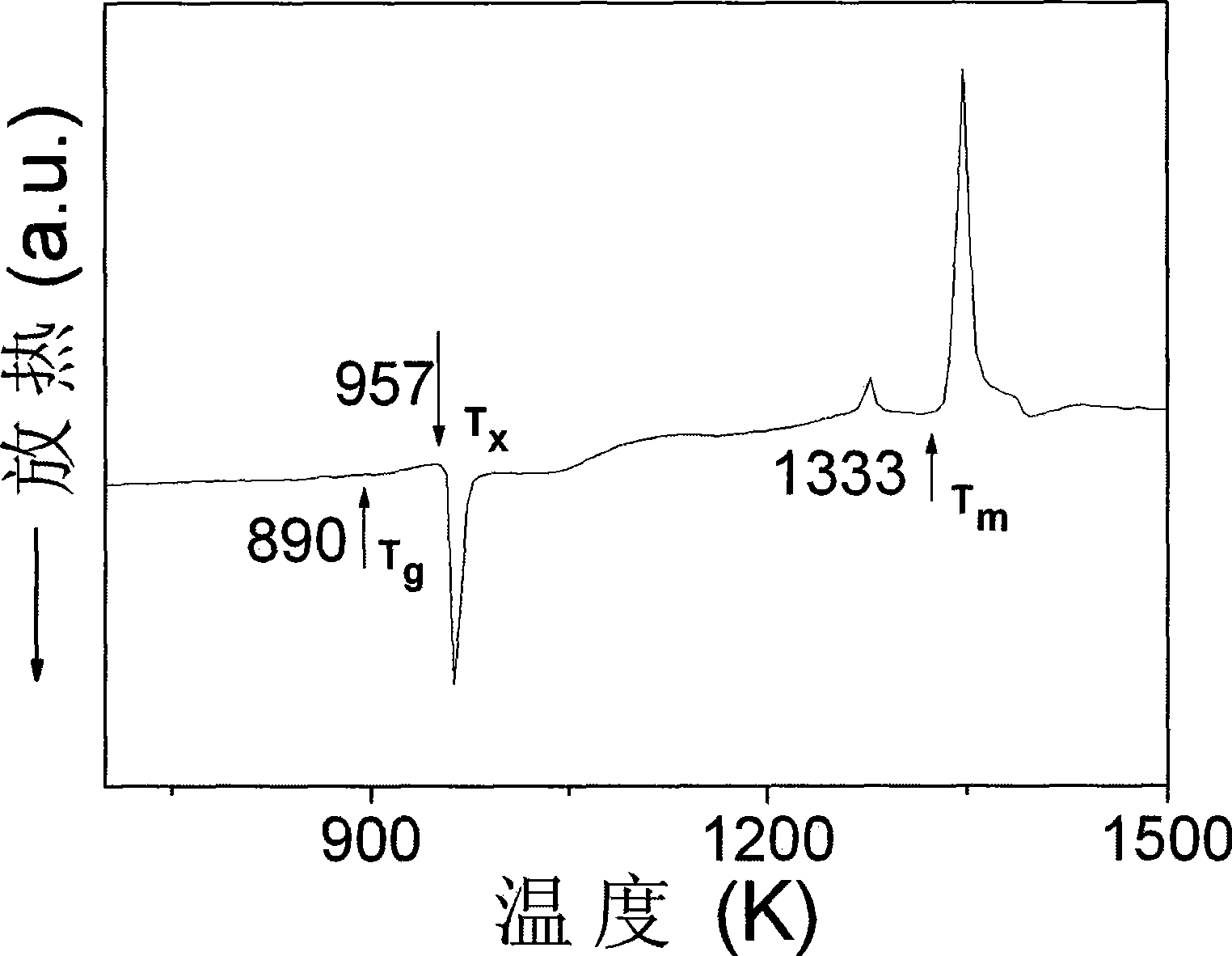

[0027] The iron-cobalt-based bulk amorphous alloy obtained in this example has better amorphous formation ability, with figure 1 , It can be seen from the figure that the alloy has a la...

Embodiment 2

[0029] The composition (atomic percentage) of the iron-based bulk amorphous alloy with hard magnetism in this embodiment is: Fe 32%, Co 32%, Zr 3%, Nd 4%, Nb 7%, B 22%. The preparation process and steps are as follows: prepare 10 grams of Fe, Co, Zr, Nd, Nb and FeB alloys of industrially pure metals according to the composition of the Fe-Co-based bulk amorphous alloy of this embodiment, and then use vacuum non-consumable arc The furnace is smelted under the protection of argon, and the smelting current density is 200A / cm 2 , the smelted alloy was turned over and smelted 4 times to obtain the master alloy; after remelting the master alloy, it was poured by copper mold negative pressure suction casting method to obtain a bulk amorphous alloy with a size of 0.8mm×10mm×80mm.

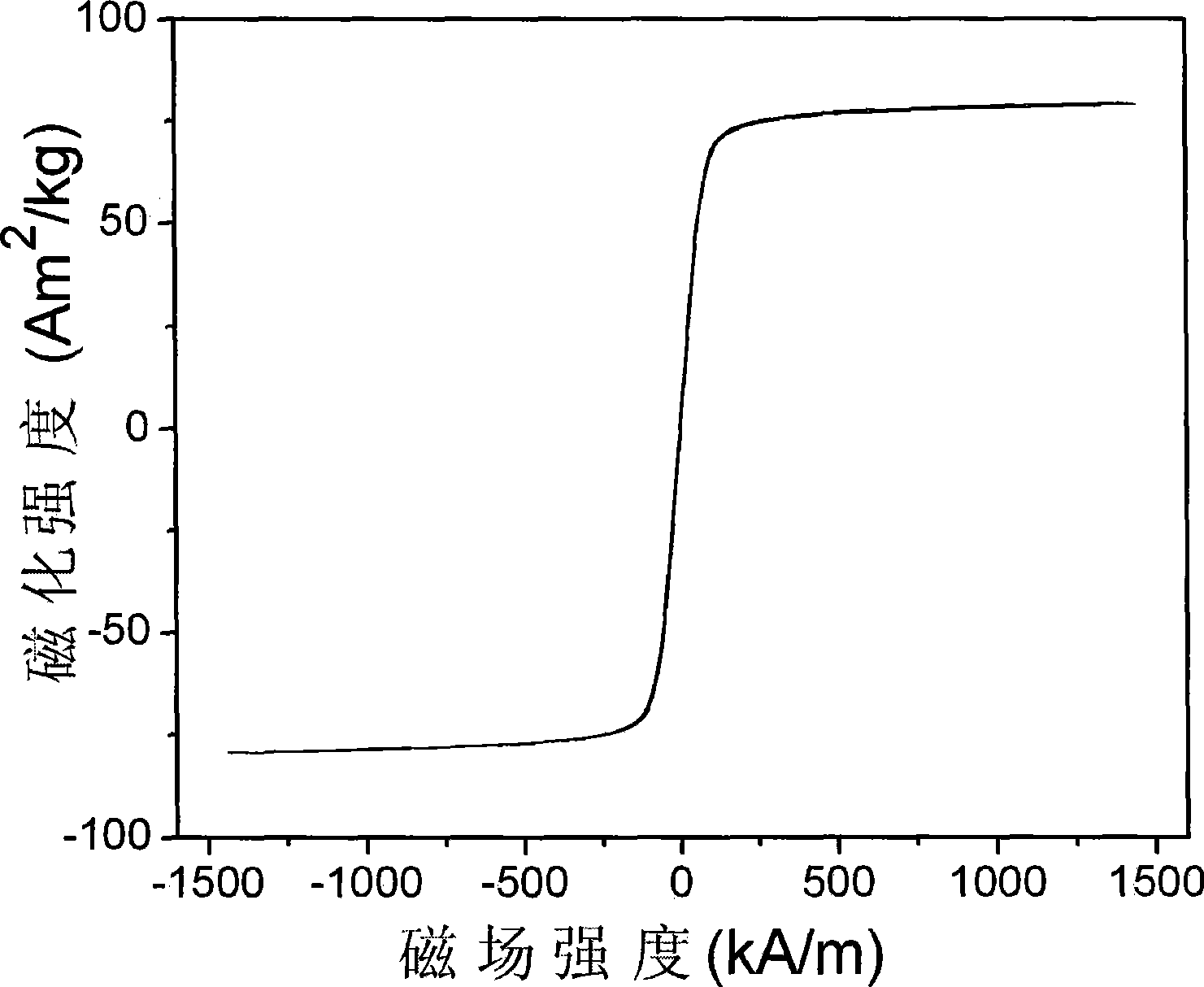

[0030] The saturation magnetization Ms≈77Am of the iron-based bulk amorphous alloy prepared in this example 2 / Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com