Band tape graduation on-line automatic detection system and method based on image processing

An automatic detection and image processing technology, which is applied in image data processing, image analysis, and bendable rulers, etc., can solve the problems of staying in the original stage, and achieve accurate detection and judgment, wide application range, and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

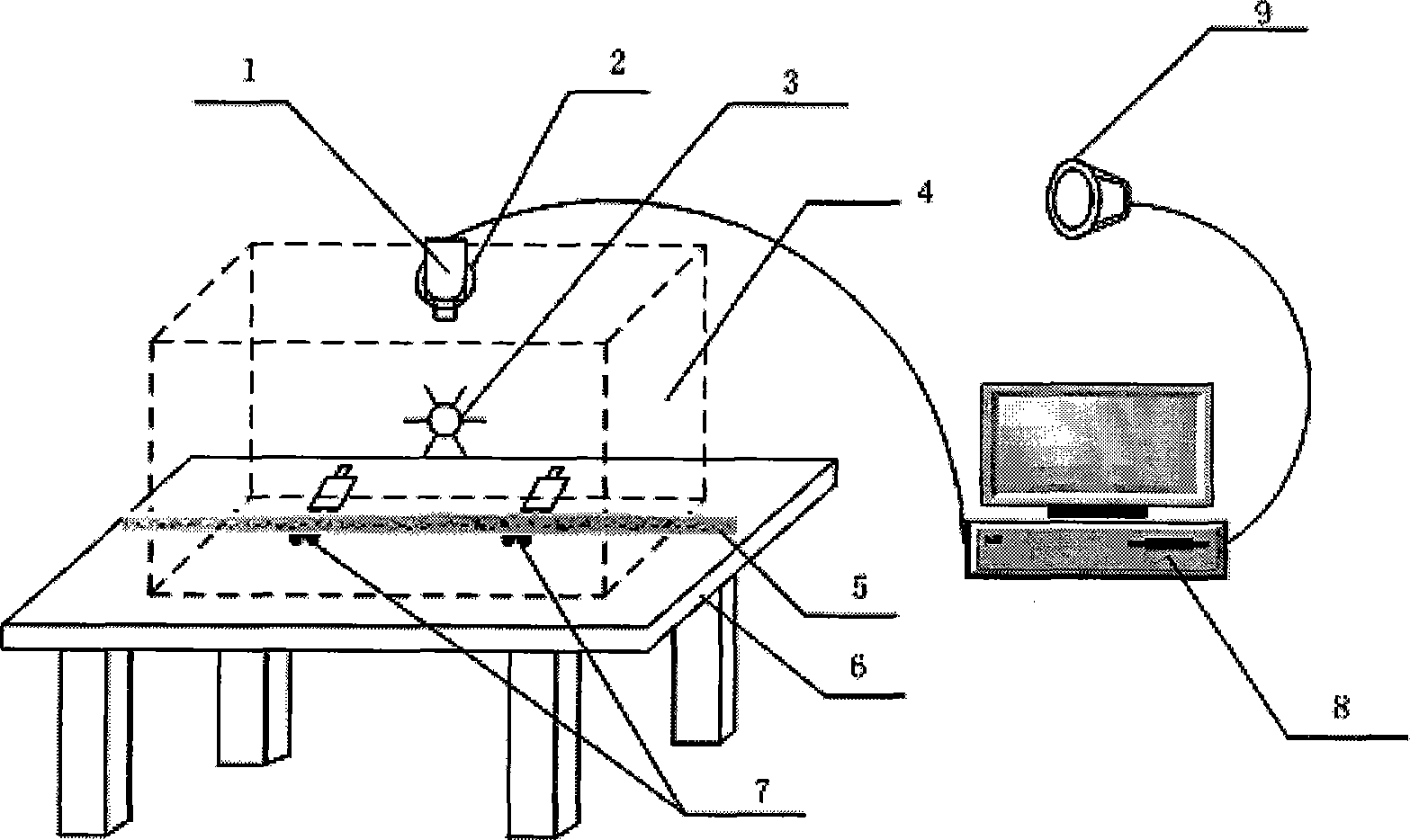

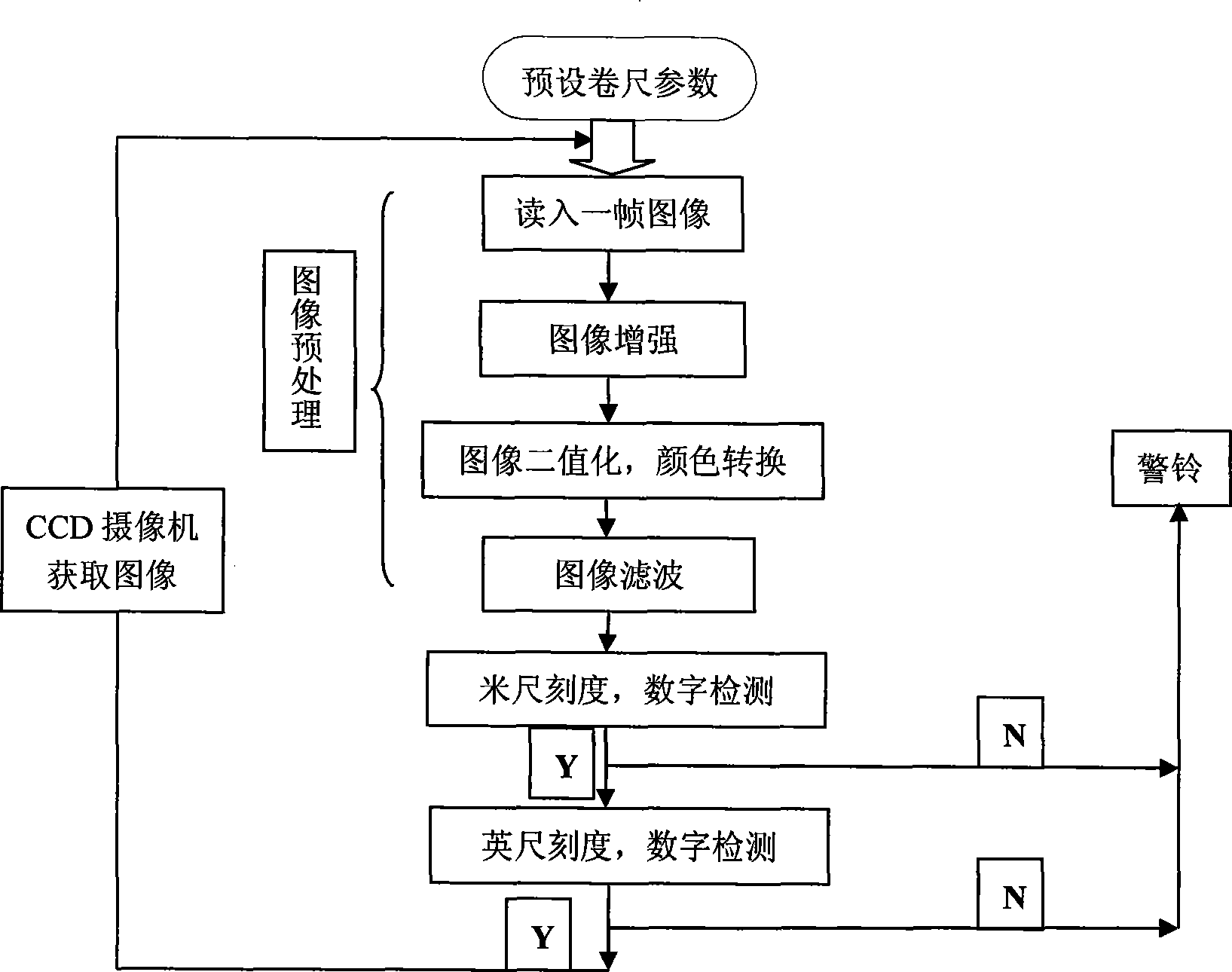

[0032] see figure 1 , the online automatic detection system of tape scale based on image processing, comprising a CCD camera 1, a computer 8 equipped with an image acquisition card and an assembly line operation platform 6, the guide tape measure 5 is housed on the said assembly line operation platform 6 tables Two tape measure slots 7 and a shielding device 4, the CCD camera 1 is fixed on the shielding device 4 directly above the tape measure, the field of view is aligned with the tape measure surface, and a direct annular epi-emission light source 2 is fixed around the CCD camera 1 On, a side LED light source 3 is fixed on the shielding device 4 on the side below the CCD camera, and the tape measure 5 can pass through two draw-in slots 7 on the operating platform 6; the computer 8 communicates with the CCD camera through its image acquisition c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com