Method of obtaining a coagulant product, product intended for manufacturing the said coagulant, and method of treating wastewater and/or industrial effluent using the said coagulant

A technology of coagulant and production method, which is applied in the fields of neutralization water/sewage treatment, flocculation/sedimentation water/sewage treatment, special treatment targets, etc., can solve the problems of inability to dehydrate, cost and expensive, and achieve the effect of saving ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

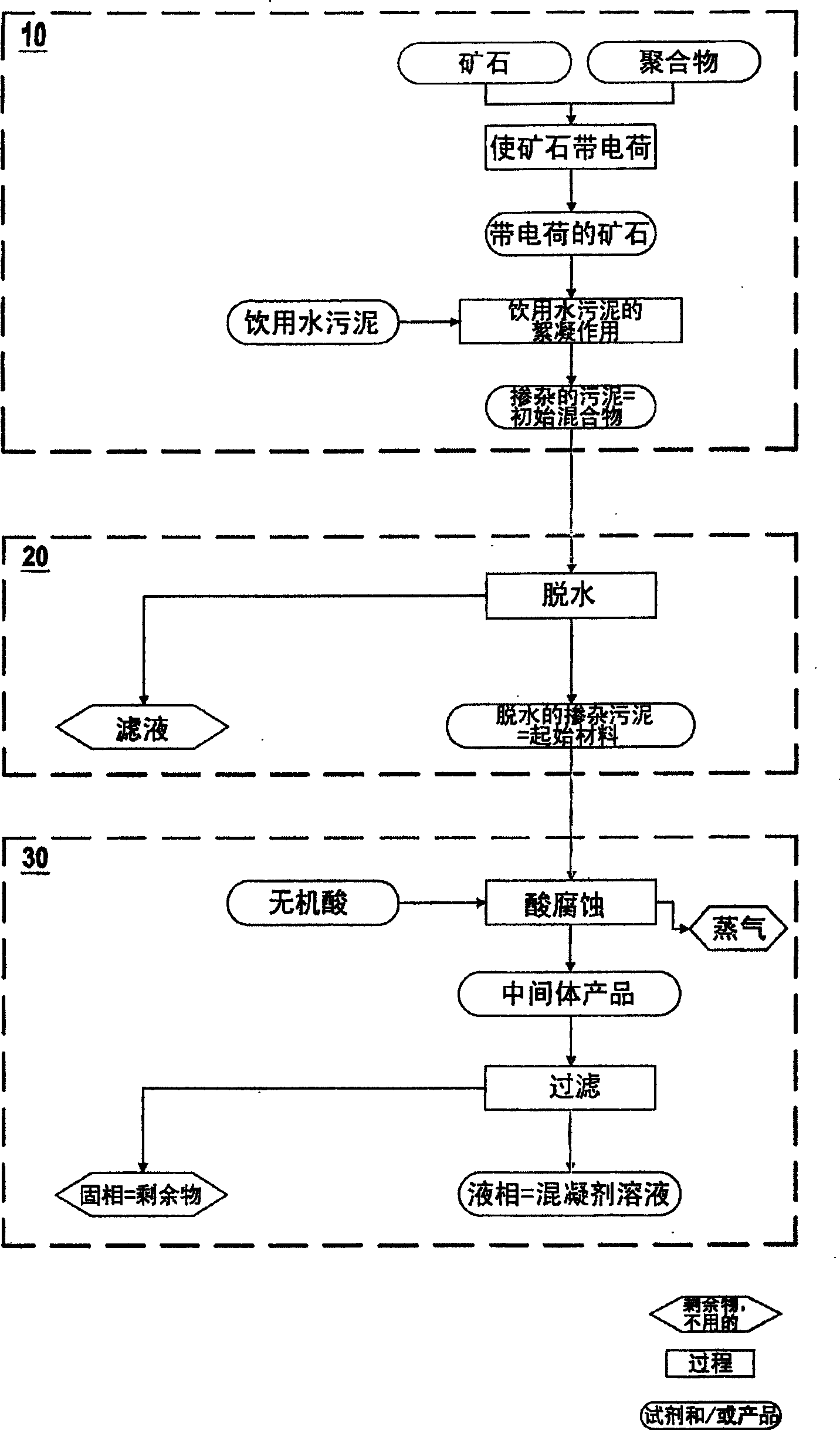

[0028] According to a feasible embodiment of the method of the present invention, the method advantageously comprises the following steps:

[0029] a') adding iron and / or aluminium-containing ore powder during the clarification treatment step of drinking water, whereby an initial mixture is obtained;

[0030] b) dehydrating the initial mixture to form the starting material;

[0031] c) acid etching the starting material by initial heating and using a mineral acid, thereby forming an intermediate product comprising an iron salt, an aluminum salt, or a mixture thereof; and

[0032] d) Filtration of the intermediate product to separate the solid phase from the liquid phase containing said coagulant product.

[0033] In this case, therefore, step a) becomes step a'), which is carried out during the clarification of water (coagulation-flocculation-drainage). In order to recover sludge doped with active materials and to facilitate the settling and elimination of materials in suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com