Vertical agitating apparatus and stirring method

A technology of a stirring device and a stirring method, which is applied in the field of vertical stirring devices and vertical stirring devices, and can solve the problems of increased measurement difficulty, increased production costs, and increased operation complexity, and achieves the goal of reducing procedures and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

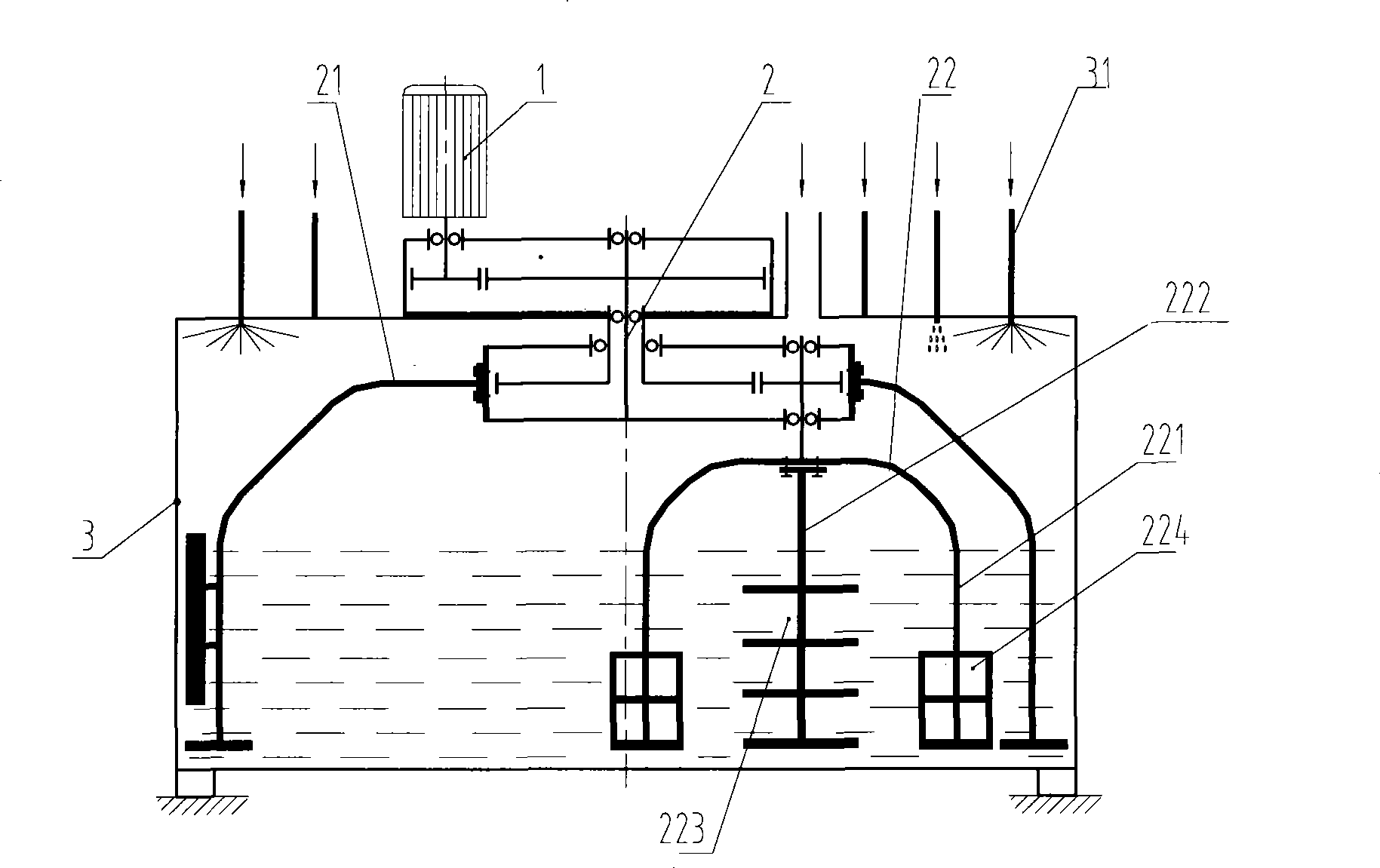

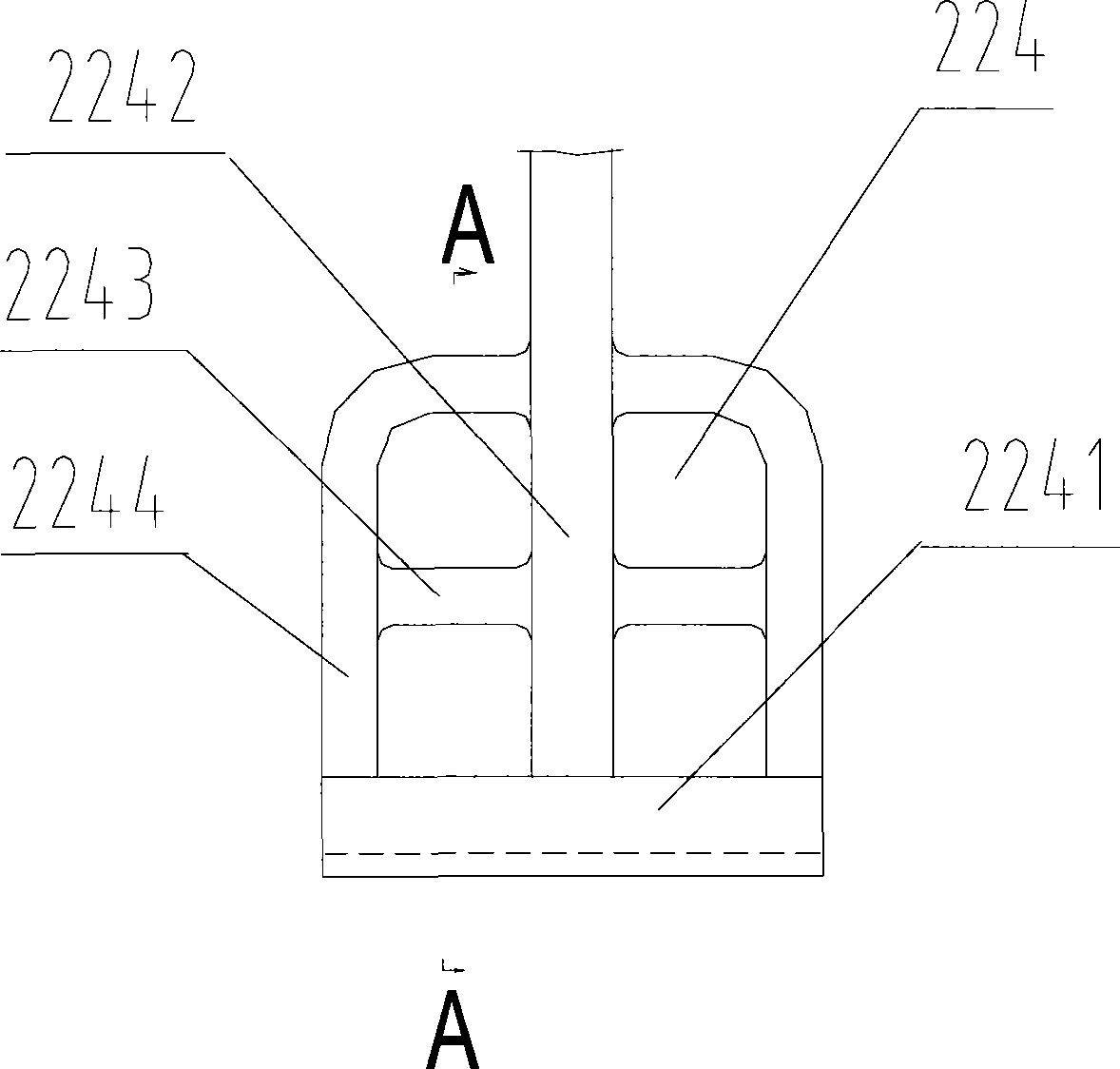

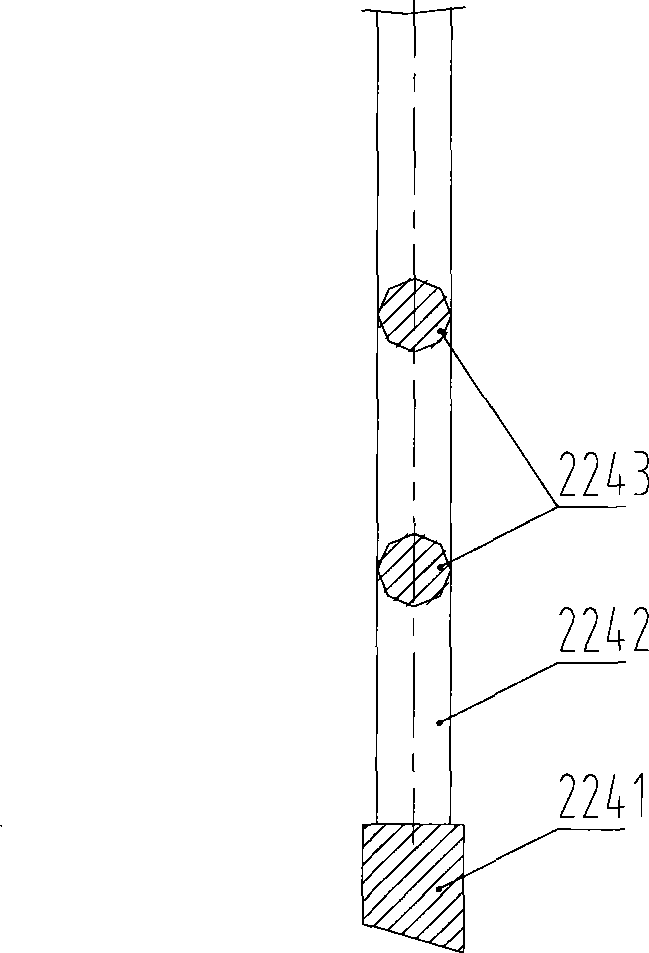

[0040] Please see figure 1 , which shows a schematic structural view of the vertical mortar mixing device provided by the first embodiment of the present invention.

[0041] Such as figure 1 As shown, the mortar stirring device includes a motor 1 , a stirring mechanism 2 , and a bucket 3 . Wherein the material bucket 3 is a cylinder with a top cover, and its interior is used to place the mortar to be stirred; the material bucket 3 is also a base for placing other mechanisms. Motor 1 is installed on the top cover of material bucket 3, and this top cover is also provided with the interface of pipelines such as various feeding pipes, water inlet pipes, is used for connecting these pipelines. The stirring mechanism 3 is vertically installed on the top cover of the material barrel 3 , and its stirring arm protrudes into the accommodating space of the material barrel 3 . The above-mentioned stirring mechanism 2 adopts a specially designed planetary stirring mechanism, which has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com