Axle count sensor

A technology of axle counting sensors and sensing devices, which is applied in the direction of instruments, counting mechanisms/items, vehicle route interaction equipment, etc., can solve the problems of complex structure, temperature resistance and durability limitations, and achieve good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

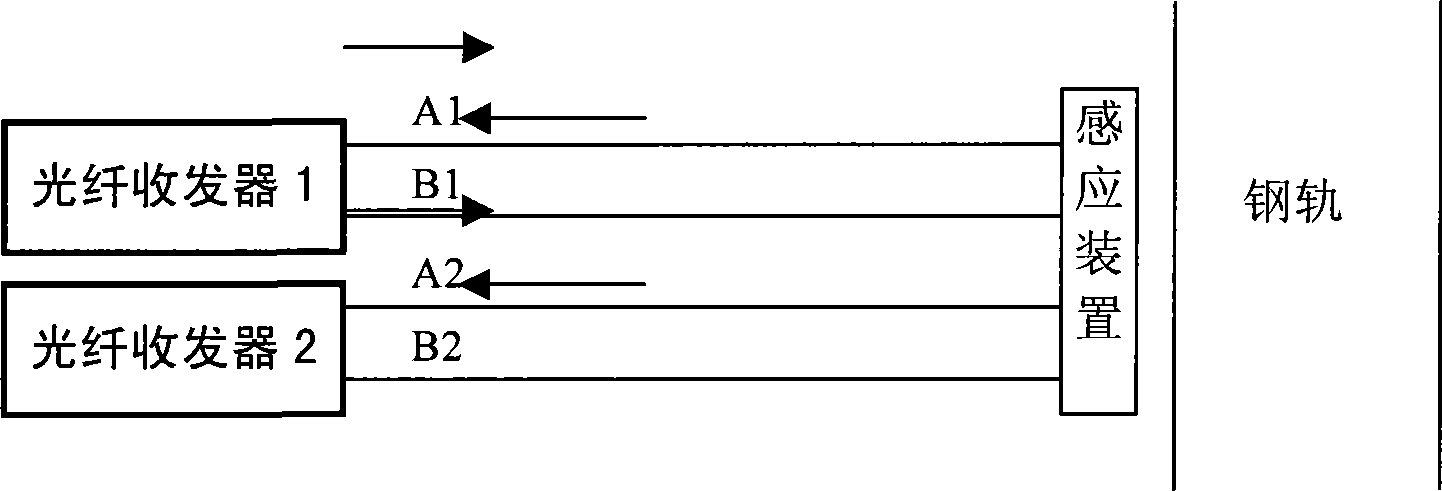

[0018] The axle counting sensor of the present invention comprises indoor optical fiber transceiver, optical fiber and outdoor sensing device, such as figure 1 As shown, the optical fiber transceiver 1 transmits optical signals to the sensing device through the optical fiber A1, and the sensing device is installed on both sides of the track (slightly higher than the guide rail) or at the bottom of the track. When no locomotive passes, the sensing device allows the light signal to pass through, and the optical fiber transceiver 1 can receive the sent light signal through the optical fiber B1. Transmission, the optical fiber transceiver 1 cannot receive the optical signal, so the passing and interruption of the axle is converted into a changing optical signal, so the optical fiber transceiver 1 converts the changing optical signal into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com