Heating type exhausting silencer of motorcycle

An exhaust muffler and heating type technology, which is applied in the direction of exhaust devices, mufflers, machines/engines, etc., can solve the problems of air pollution emissions, exhaust gas cannot be converted, catalytic converter cannot work, etc., and achieve a reasonable structure , Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described in conjunction with the embodiment that accompanying drawing provides:

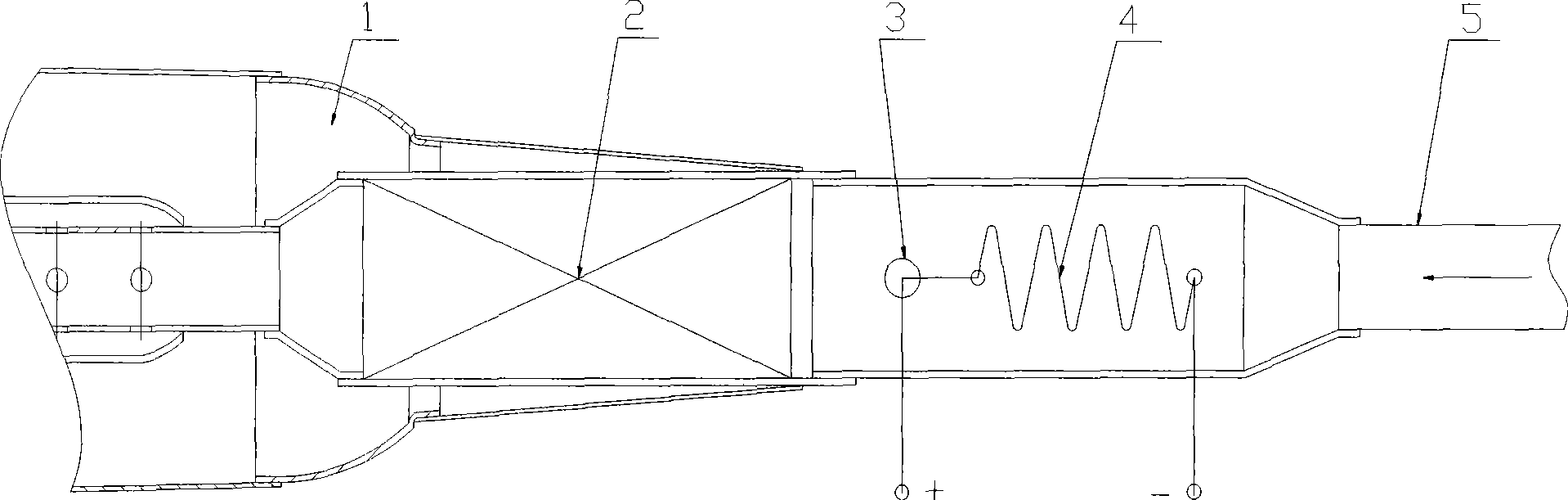

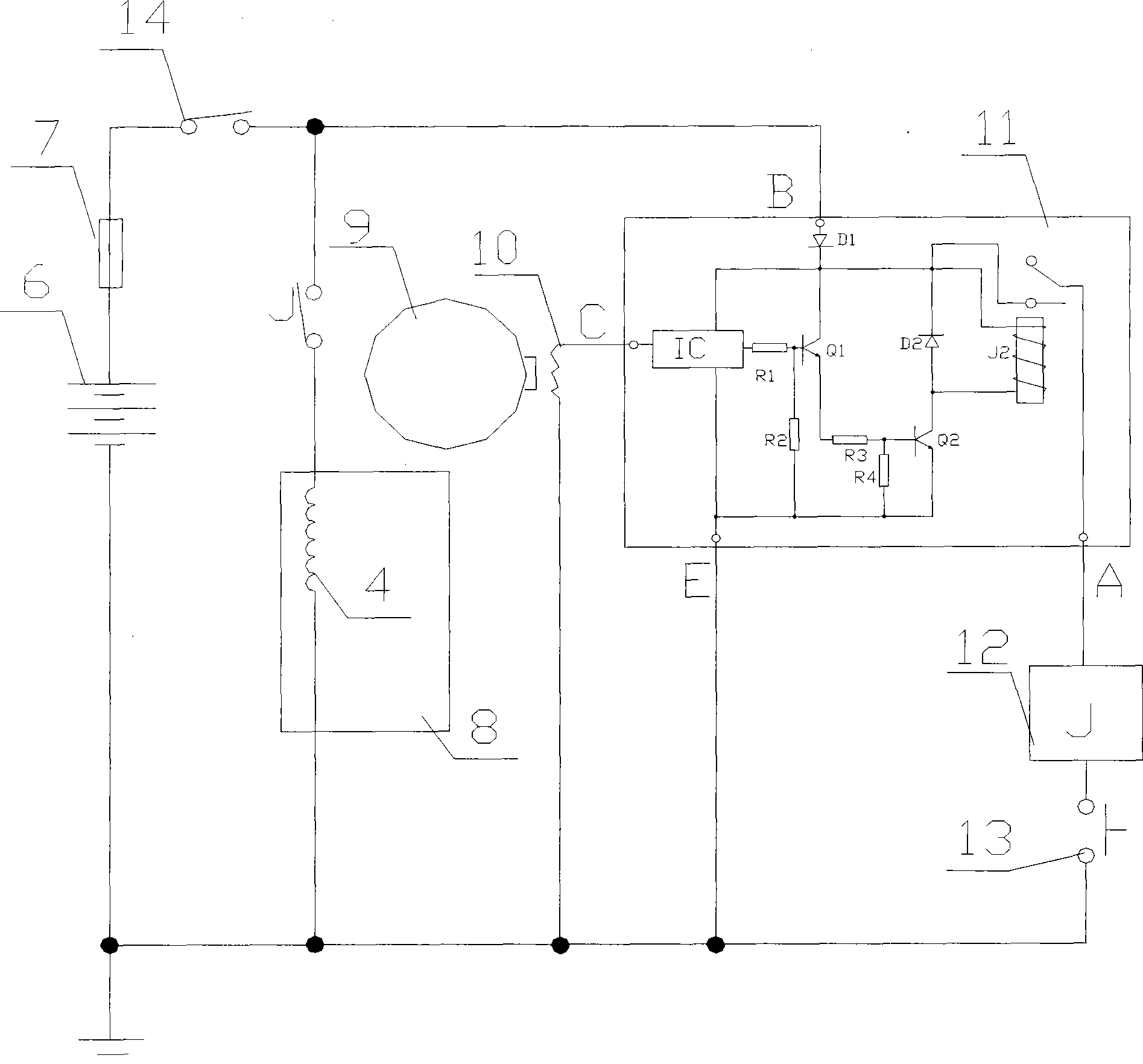

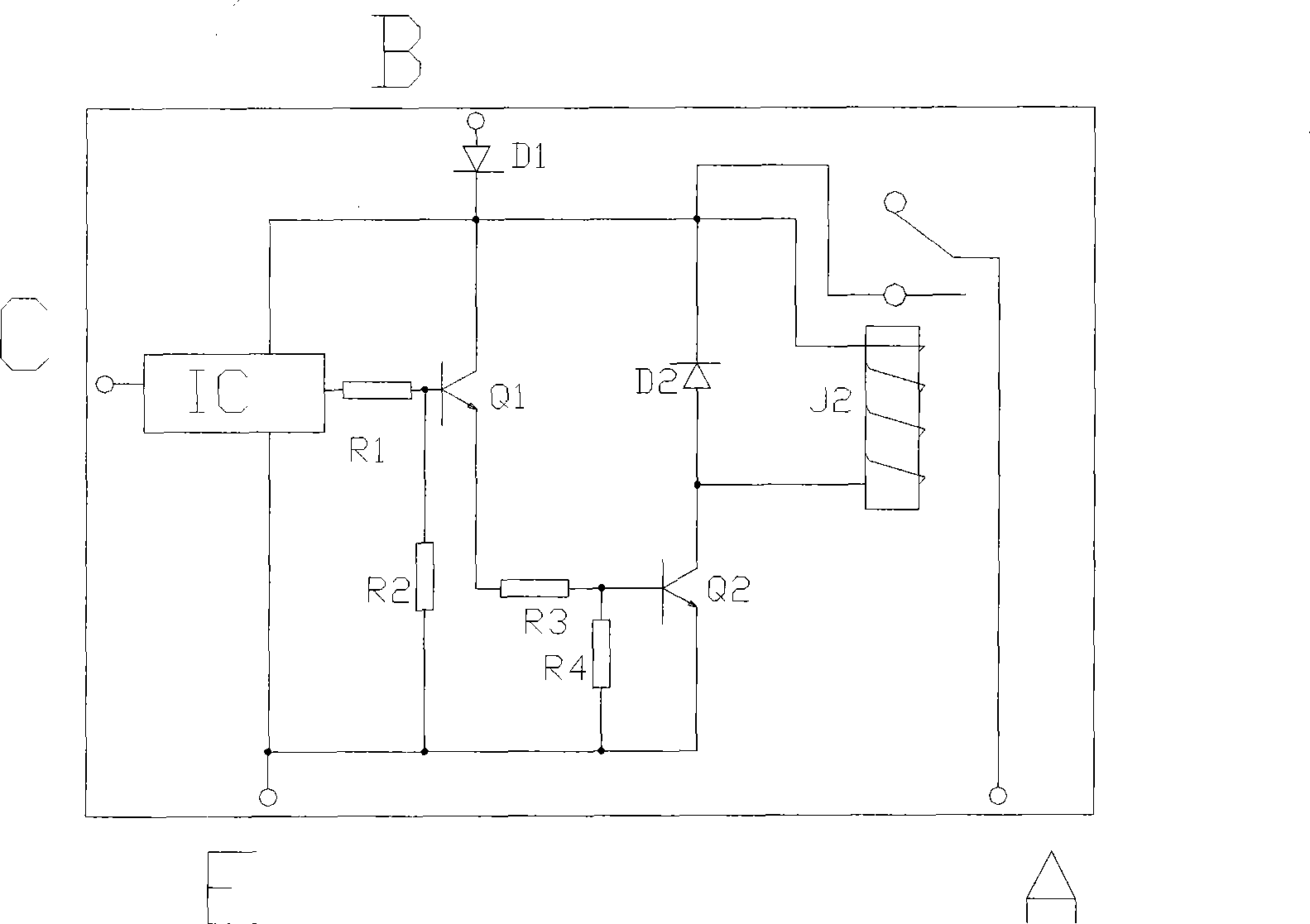

[0012] Such as figure 1 Shown, the present invention comprises exhaust pipe 5 and muffler 1 and catalytic converter 2, and exhaust pipe 5 and muffler 1 are combined to form exhaust channel, and catalytic converter 2 is set between muffler 1 and exhaust pipe 5 , a heating resistor 4 and a temperature sensor 3 are arranged between the exhaust pipe 5 and the catalytic converter 2; the working process of the present invention is: after the engine is started, the exhaust gas passes through the exhaust pipe 5 and flows into the catalytic converter after being heated by the heating resistor 4 2. Finally, it is discharged into the atmosphere through the muffler 2; when the engine is just started, the temperature of the exhaust gas at the temperature sensor 3 is too low to reach the ignition temperature of the catalytic converter, but after being heated by the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com