Shearing square glass prism for implementing shearing electronic speckle interference

A technology of electronic speckle interference and square prisms, applied in prisms, optics, measuring devices, etc., can solve the problems of expensive devices and poor quality of interference fringes, and achieve simple structure, low cost, and good imaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

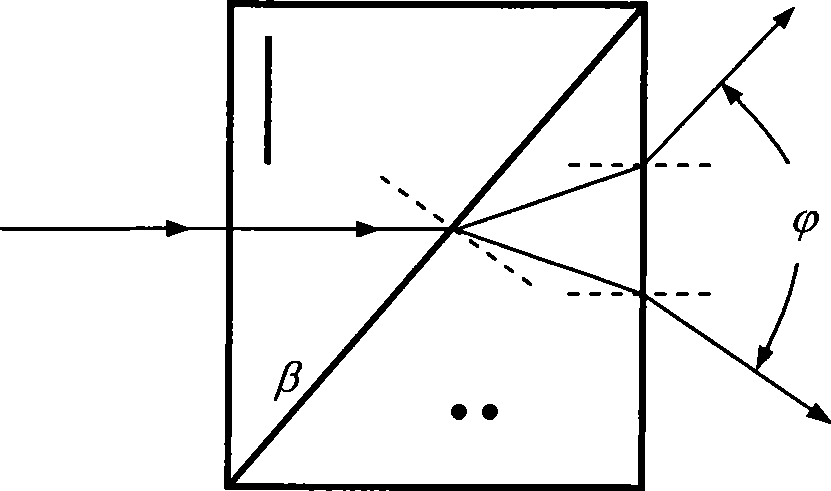

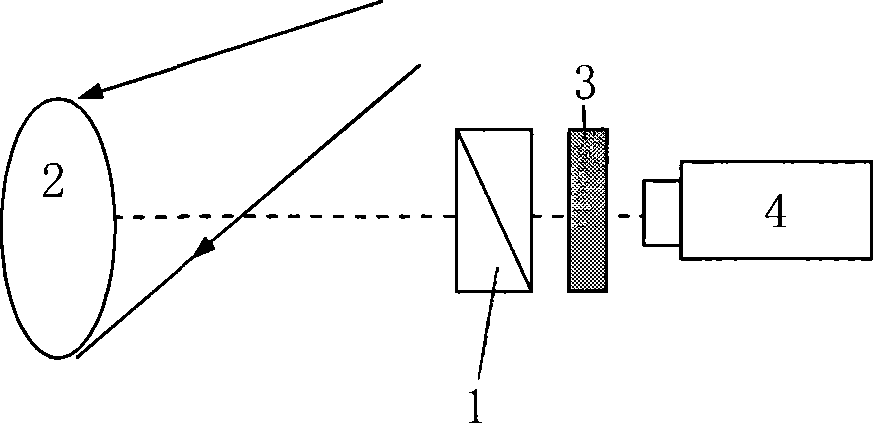

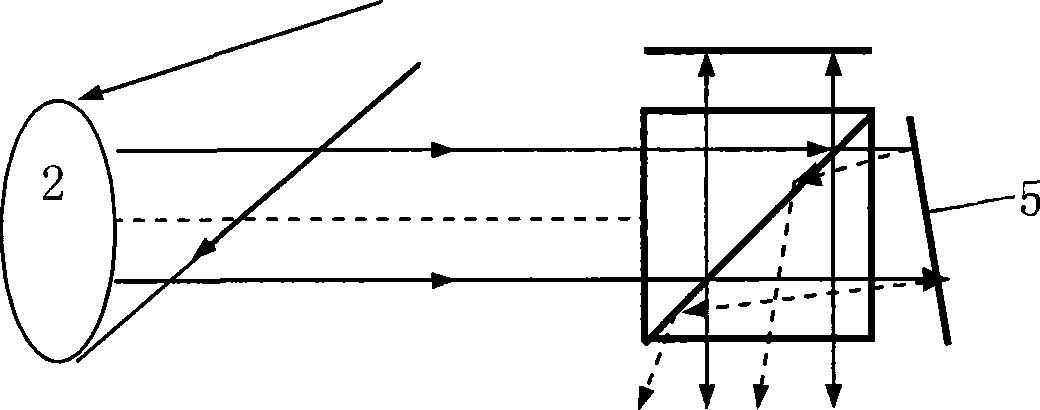

[0022] Such as Figure 4 Shown, shearing square prism of the present invention is made up of two right-angled triangular prisms that ordinary optical glass grinds, and the inclined-plane of wherein a right-angled triangular prism is plated with semi-transparent and semi-reflective film, and the inclined-plane of these two right-angled triangular prisms uses optical Glue together to form a square prism. A small wedge angle α is ground off one side of the square prism to form a bevel. The wedge angle can be selected from 1′ to 20′ according to the sensitivity requirements. When grinding Grinding inwards takes the edge where the reflective surface intersects with the slope of the right-angled triangular prism as the baseline. The light incident surface and outgoing surface of the square prism are coated with anti-reflection coating, and the two reflection surfaces are coated with total reflection coating. Such as Figure 5 As shown, the incident light is reflected at a non-righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com