Preform and container for radiosensitive products and method for the manufacturing thereof

A technology for prefabricated parts and containers, applied in the direction of bottles, etc., can solve the problems of high concentration of additives and unsatisfactory light shielding performance, and achieve the effect of improving intrinsic viscosity

Inactive Publication Date: 2009-05-13

RESILUX NV

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] European patent application EP 0 974 438 A1 by TEIJIN Ltd also describes polymer blends, but said polymer blends are for transparent containers, the light-shielding properties of which appear to be unsatisfactory, or at least require significant improvement

[0014] European patent application EP 0 273 897 A2 of MONSANTO EUROPE S.A. describes pressure vessels of the aerosol type made of transparent preforms made of a mixture of PET and styrene-maleic anhydride (SMA) copolymer type additives Composition, but the concentration of additives is still up to 30%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

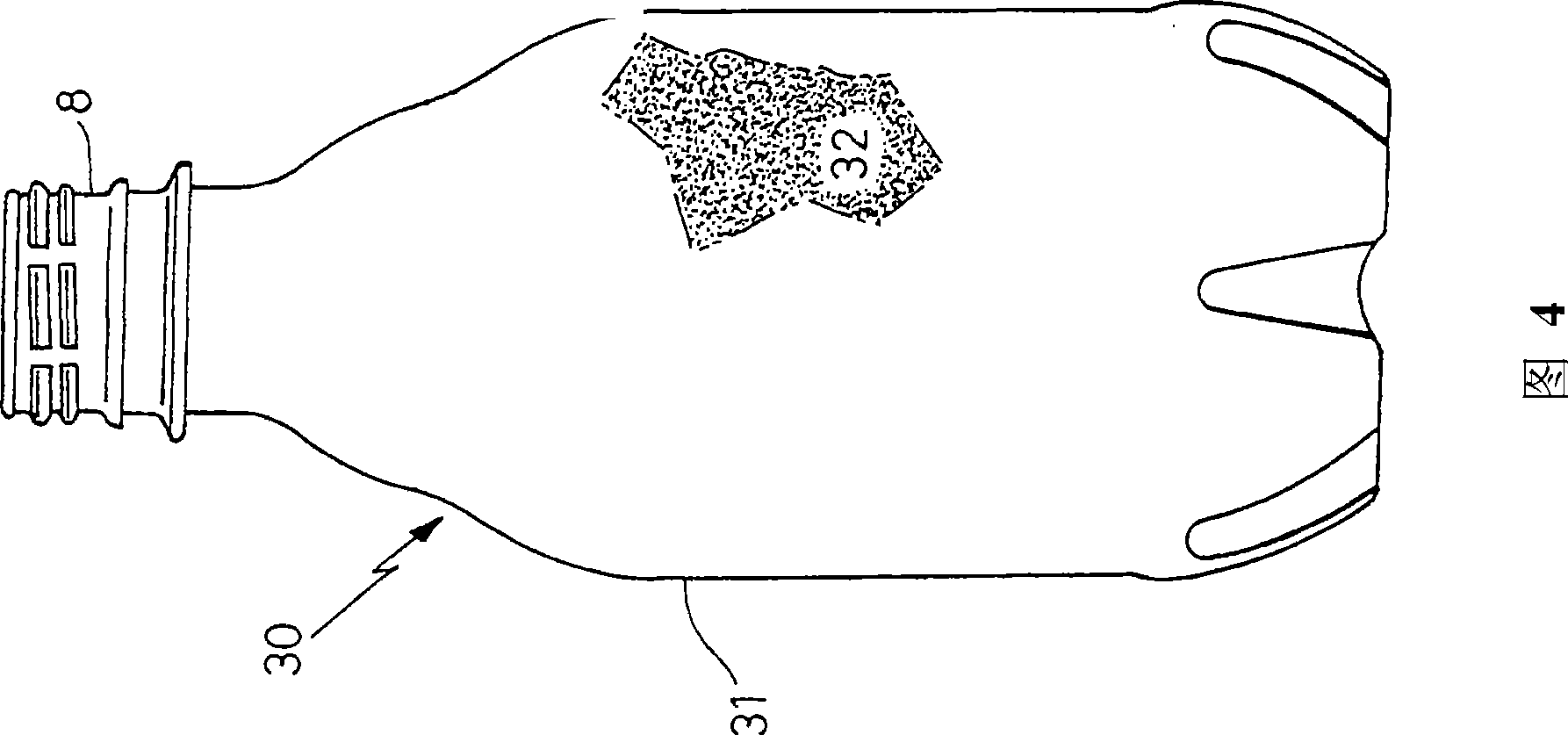

[0079] In a typical comparison, a one-liter multilayer bottle with a white PET-black PET-white PET structure weighs 26 grams when manufactured according to the invention using polymer additives, and 32 grams when manufactured by conventional techniques using large amounts of pigments , which means saving about 25% of the material, which is a considerable amount.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

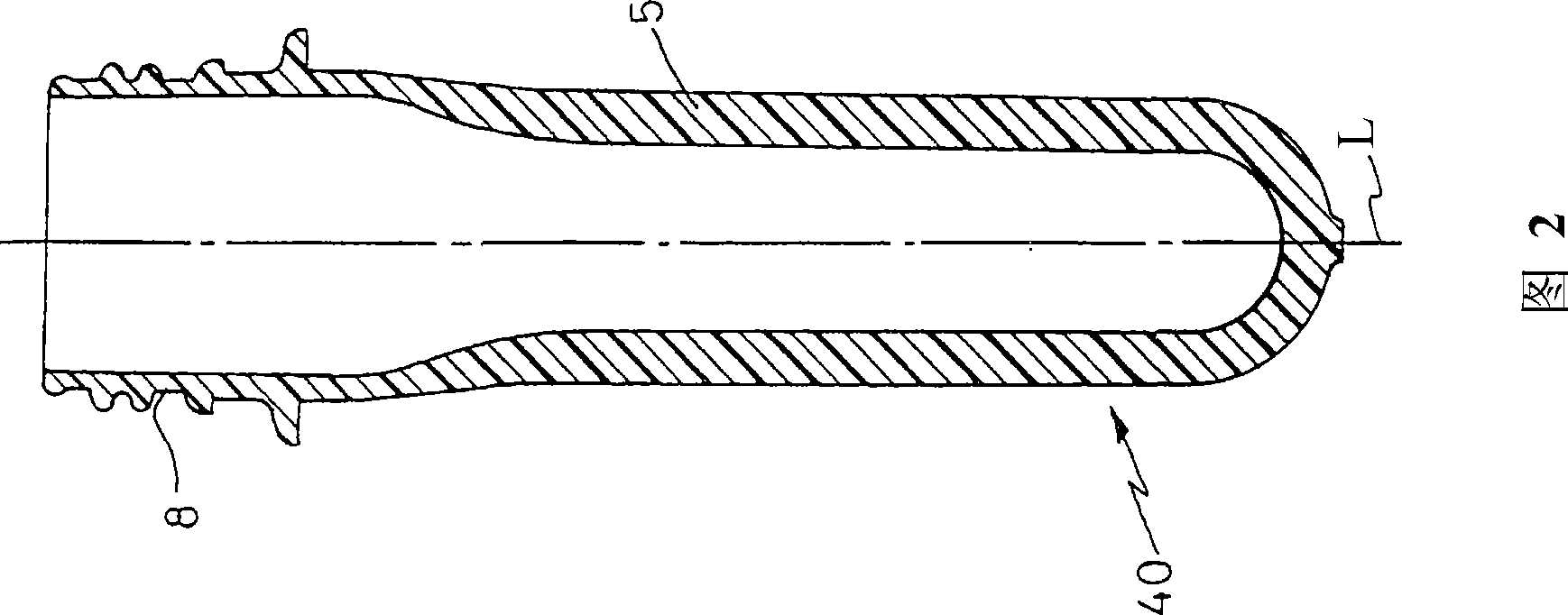

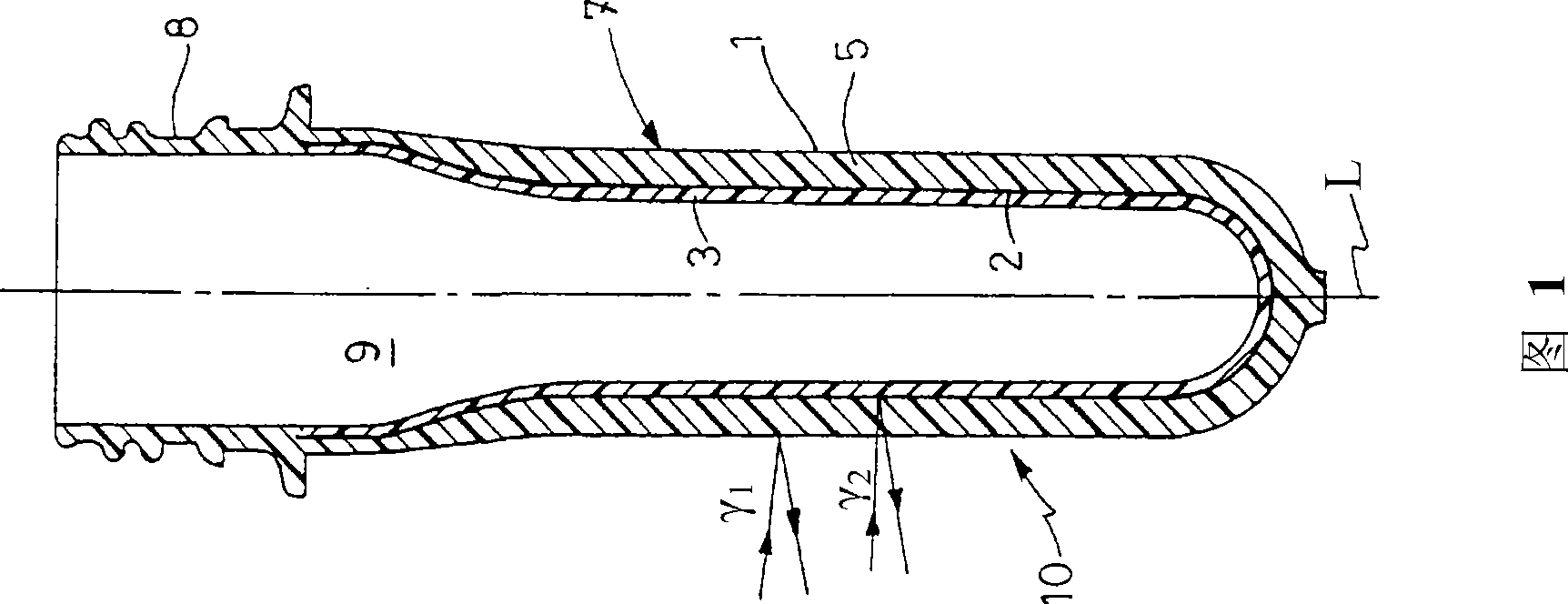

The present invention provides a prefabricated component which is used for container as intermediate product. The container is used for containing product therein. The product is food or milk product which is sensitive to radiation, especially to light. The prefabricated component is at least composed of a base layer (1) which is mainly composed of plastic-based material, and furthermore the base layer (1) is added with a certain amount of additive (5). The invention is characterized in that the prefabricated components (10, 20) are almost nontransparent in the whole area, wherein the plastic additive (5) with a relatively low percentage is introduced for generating nontransparent appearance (22) thereby protecting the confined inner space (9) from the external radiation (V1, V2) at the condition of normal atmosphere. The external radiation is specifically electromagnetic radiation, and more particularly the effect of light.

Description

technical field [0001] The present invention relates to containers for containing radiation-sensitive, in particular light-sensitive, essentially food industry products, more particularly milk and further dairy products, including those fortified or containing fruit Nutraceuticals and dairy products. [0002] The invention also relates to a preform as a semi-finished product for the production of such a container, consisting of at least one base layer made of predominantly plastic material into which a certain amount of additives has been introduced. Background technique [0003] Plastic containers, including bottles made of polyester, especially polyethylene terephthalate (PET), are increasingly used to package food and beverages. PET containers were originally used for carbonated beverages, such as soda. They have since made important advances in all areas of the food segment, such as beverages (including milk). [0004] Polyethylene terephthalate is an excellent materi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C49/06B65D1/02C08L67/02B29C49/22B29C47/06

CPCC08L23/12

Inventor W·迪里克

Owner RESILUX NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com