Method for preparing ginkgo leaf extract powder using supercritical liquid desiccation and device thereof

A technology of supercritical fluid and ginkgo biloba, which is applied in the direction of drying solid materials, making medicines into special physical or ingestible devices, and medical raw materials derived from ginkgo biloba. Problems such as destruction and carbon dioxide waste, achieve the effect of small average particle size, narrow particle size distribution, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

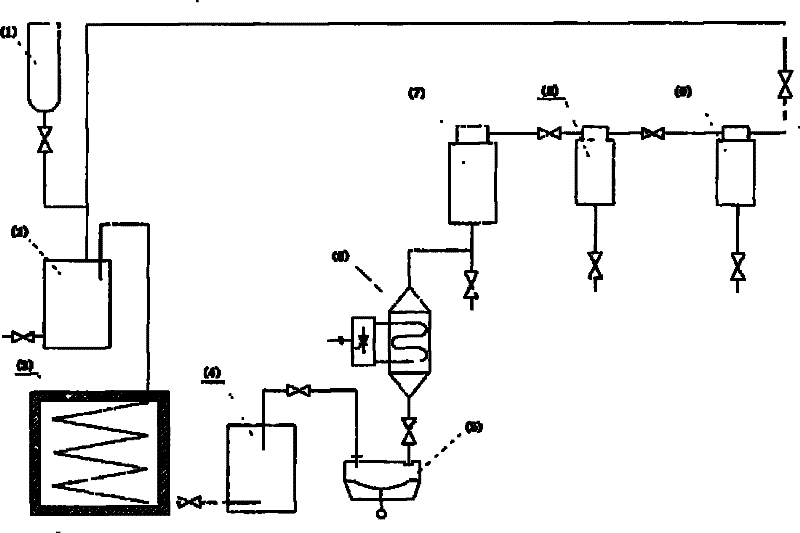

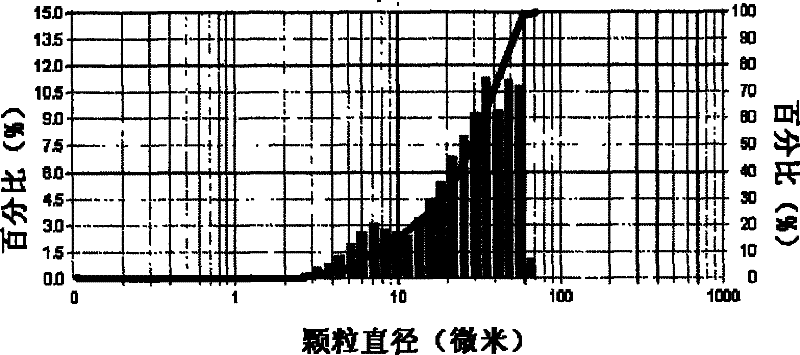

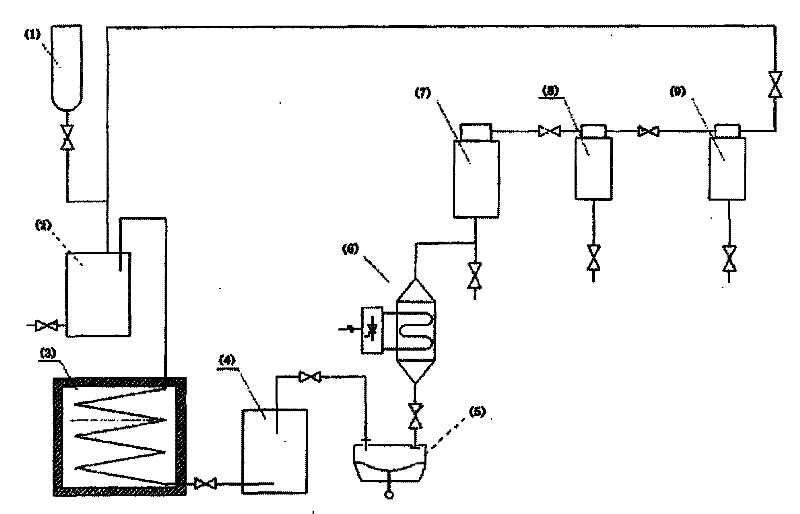

[0022] A method for preparing ginkgo leaf extract powder by supercritical fluid drying is realized by a set of supercritical drying devices with carbon dioxide recycling. Raw material is the alcoholic solution of the ginkgo biloba extract of 130g and containing alcohol 90%wt. The pressure of supercritical carbon dioxide in the drying chamber cylinder 7 needs to be controlled at 10 MPa, and the hot water in the hot water jacket of the drying chamber cylinder 7 and the primary separation cylinder 8 and the secondary separation cylinder 9 is heated by the heater 6 , the temperature in the cylinder 7 of the drying chamber is controlled at 40°C, the temperature in the primary separation cylinder 8 is controlled at 30°C, and the temperature in the secondary separation cylinder 9 is controlled at 20°C. The carbon dioxide is cooled to 0°C-5°C through the refrigerating unit 3, and is continuously transported to the drying chamber cylinder 7 through the carbon dioxide delivery pump 5 af...

Embodiment 2

[0025] A method for preparing ginkgo biloba extract powder by supercritical fluid drying, placing the alcohol solution of the impurity-free ginkgo biloba extract in a sealed drying chamber cylinder, then feeding carbon dioxide at a flow rate of 20L / h, the carbon dioxide The temperature is 0°C, the cylinder pressure of the drying chamber is controlled at 13 MPa, and the temperature is 60°C. After the carbon dioxide becomes a stable supercritical fluid, it is then continuously replaced and dried for 4 hours, and finally a pale yellow dried product powder of Ginkgo biloba extract is obtained. When the carbon dioxide in the drying chamber becomes a stable supercritical fluid, start the primary and secondary separation cylinders, and control the pressure of the primary and secondary separation cylinders to 3.5MPa and the temperature to 20°C. The alcohol in the alcohol solution of Ginkgo biloba extract can be recycled and reused. After the used carbon dioxide is separated from the a...

Embodiment 3

[0029] A kind of method that prepares Ginkgo biloba extract powder with supercritical fluid drying, the alcoholic solution of the Ginkgo biloba extract without impurity is placed in the cylinder body of sealed drying room, then feeds carbon dioxide with the flow velocity of 45L / h, the carbon dioxide The temperature is 5°C, the cylinder pressure of the drying chamber is controlled at 30MPa, and the temperature is 75°C. After the carbon dioxide becomes a stable supercritical fluid, it is then continuously replaced and dried for 8 hours, and finally a light yellow dried product powder of Ginkgo biloba extract is obtained. When the carbon dioxide in the drying chamber becomes a stable supercritical fluid, start the primary and secondary separation cylinders, and control the pressure of the primary and secondary separation cylinders to 5.0 MPa and the temperature to 40°C. The alcohol in the alcohol solution of Ginkgo biloba extract can be recycled and reused. After the used carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com