Independent thermal source heated air conditioner system of engineering machinery vehicle

A technology for construction machinery and vehicle air conditioning, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc., which can solve the problems of engine overcooling, insufficient heat of engine cooling water, unstable heat production, etc., and achieve high heat production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

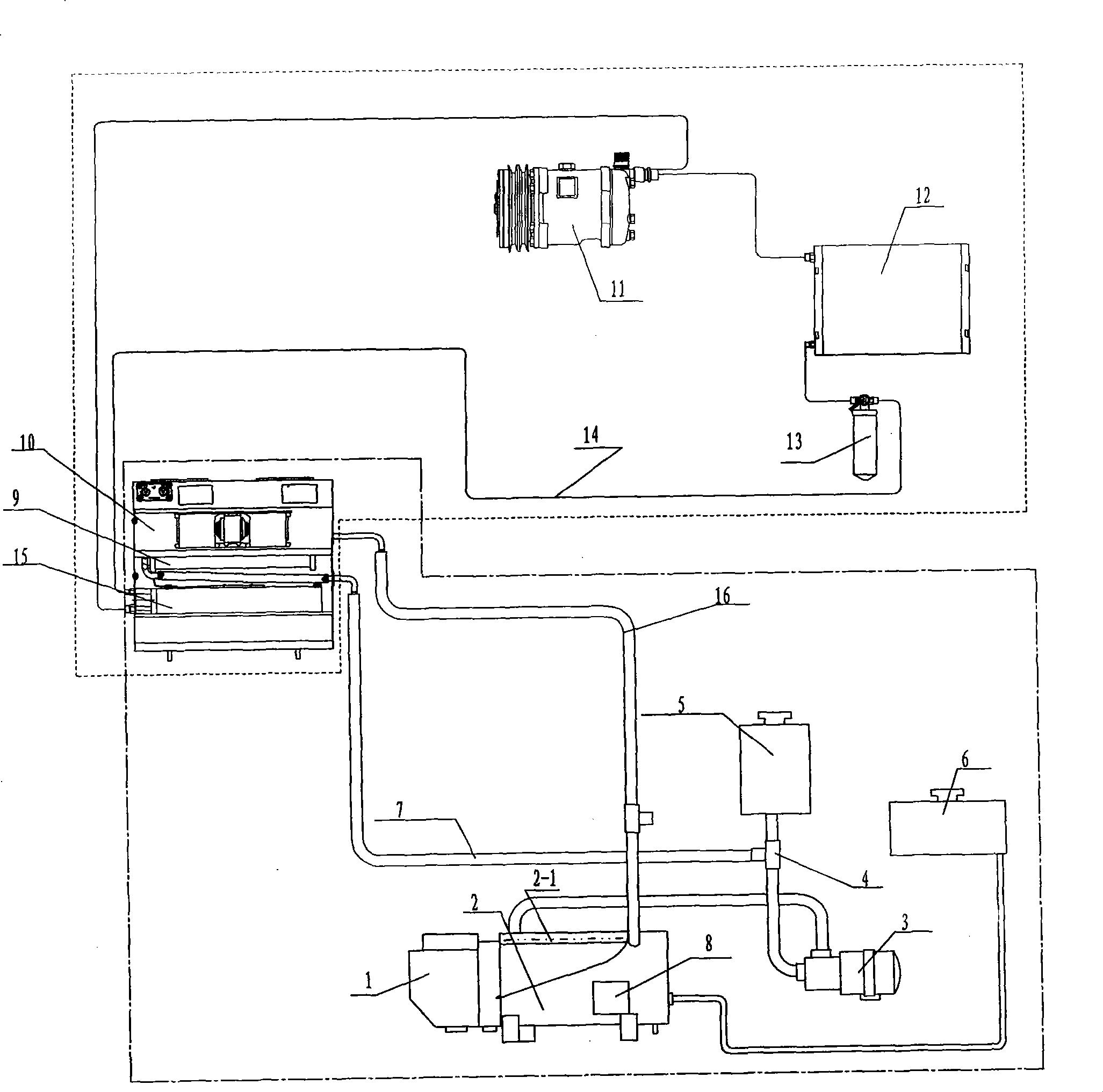

[0010] As shown in the accompanying drawings, the present invention includes two parts of a refrigeration system and a heating system. The dotted frame above is the cooling part, which is mainly composed of a compressor 11 , a condenser 12 , an accumulator 13 , a refrigeration pipeline 14 and an evaporation core 15 connected to the compressor 11 and the accumulator 13 . The dotted line box below is the heating part, mainly composed of motor 1, burner 2, water pump group 3, stop valve 4, expansion tank 5, oil tank 6, return pipe 7, electrical control system 8, heater core 9, blower 10 and so on. The combustion chamber of the burner 2 is connected to the oil tank 6 with a pipeline, and the burner 2 is provided with an outer interlayer cavity 2-1, and the outer interlayer cavity is connected to the expansion tank 5 through the connecting pipeline and the water pump 3 installed on the connecting pipeline. 3. A shut-off valve 4 is installed in the connecting pipeline with the expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com