Continuous track raking loader

A rake loader and crawler technology, which is applied in the field of continuous crawler rake loader, can solve the problems of discontinuous work of the rake bucket rock loader, high labor intensity of workers, and inability to use thin coal seams, etc., and achieves wide practicability, compact structure, and convenience. The effect of loading and conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

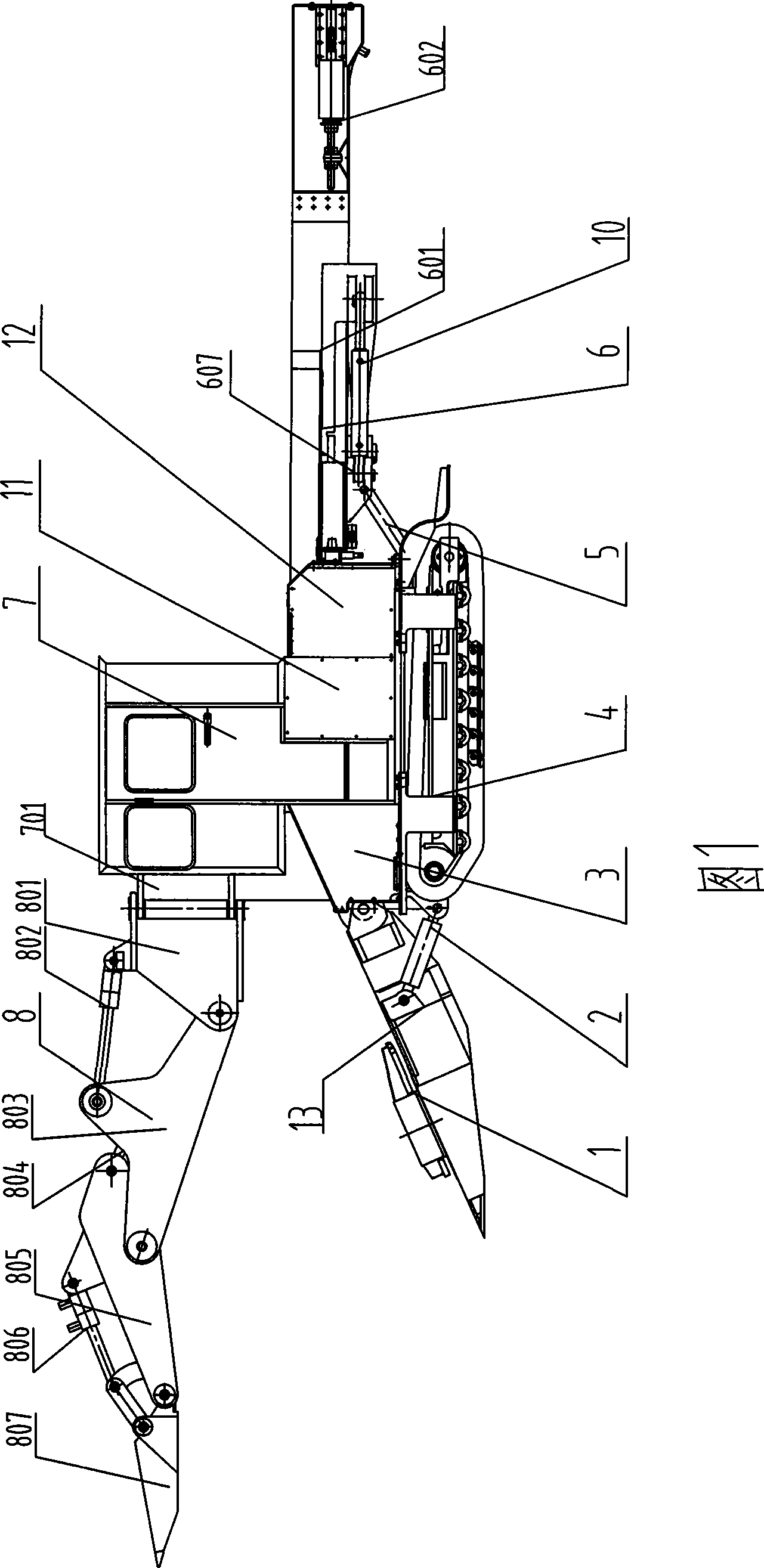

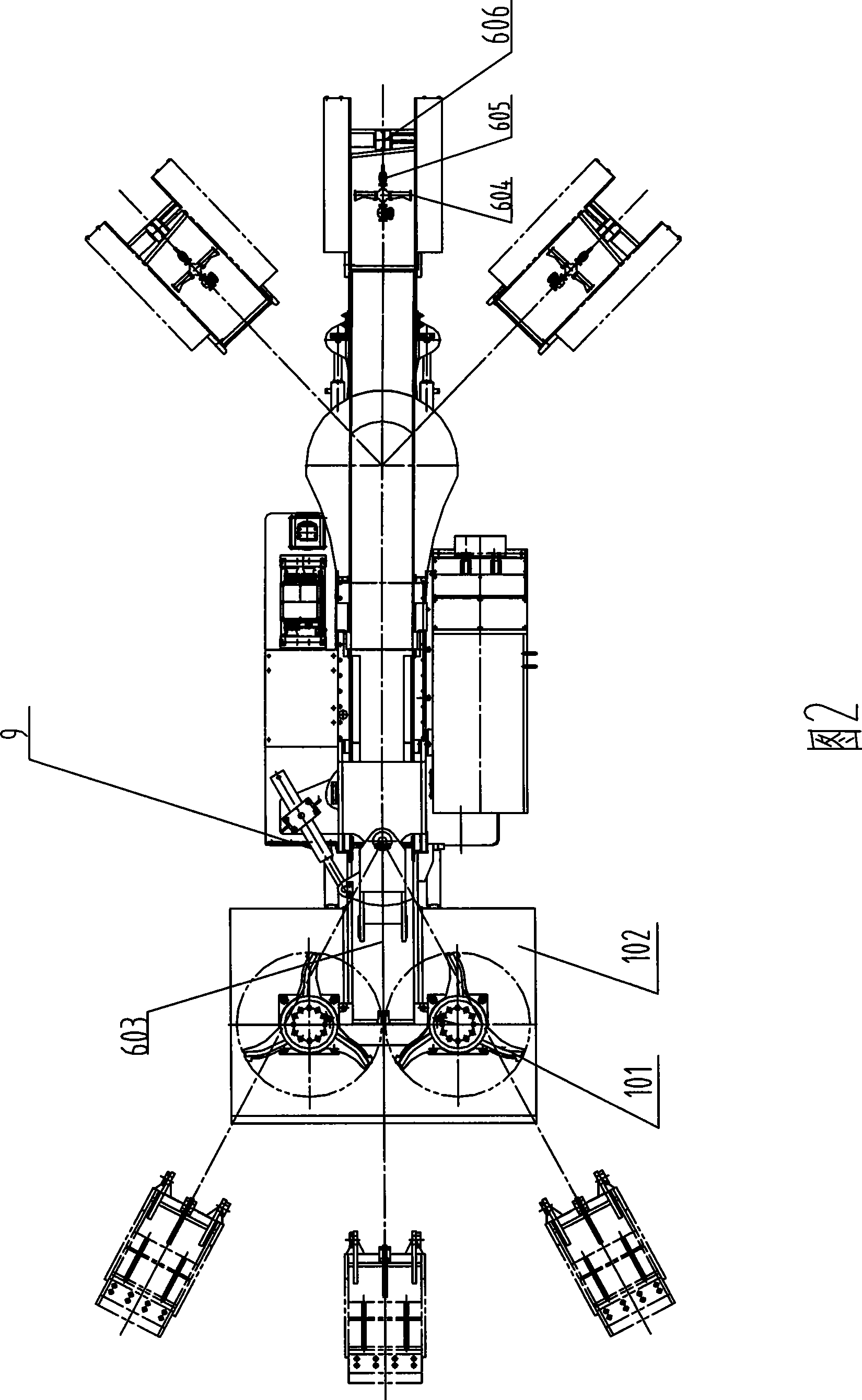

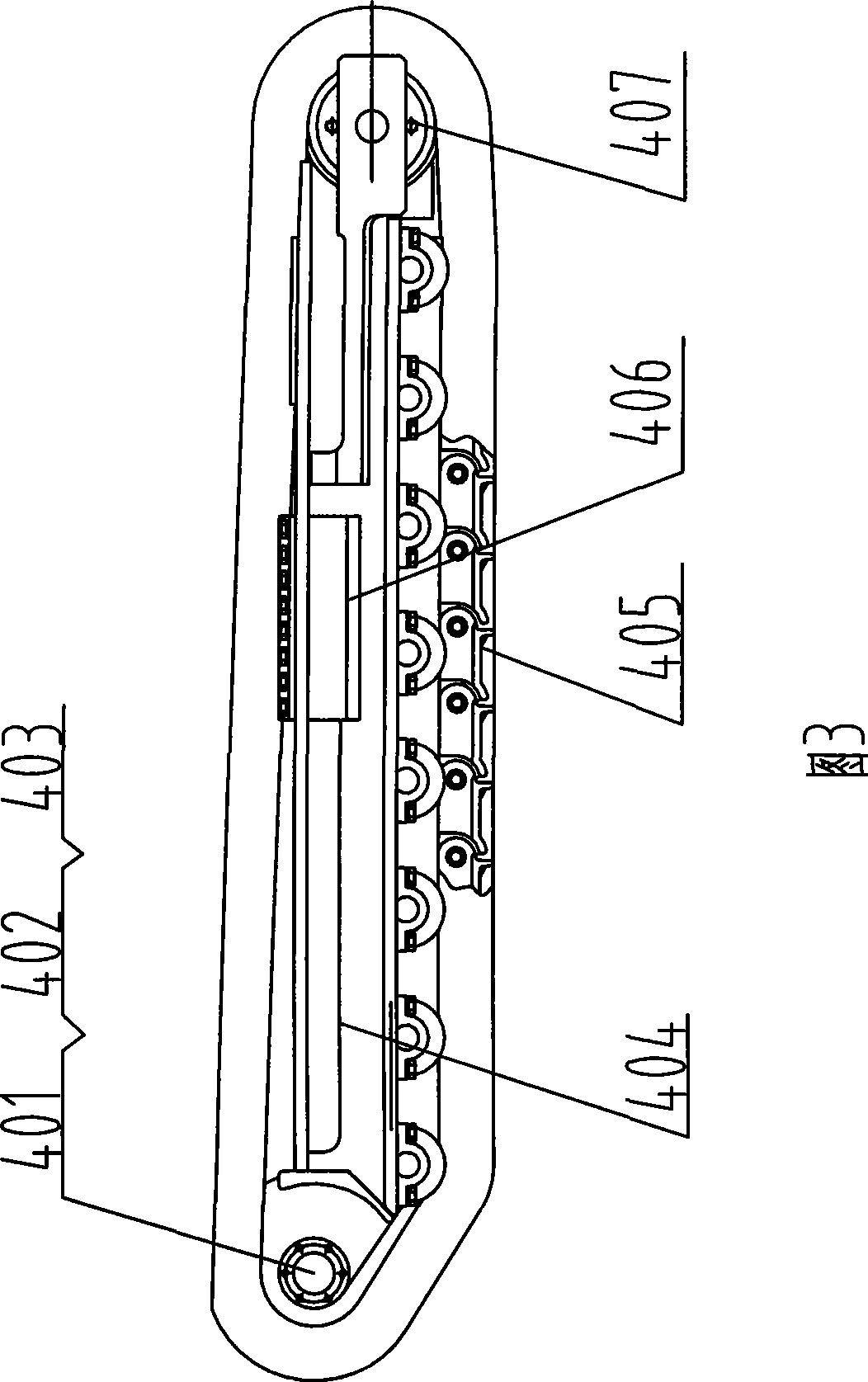

[0012] As shown in the accompanying drawings, the main engine is mainly composed of a driving device 3, a traveling device 4 and a cab 7, and its height is lower than 2 meters. The driving device 3 and the cab 7 are installed above the traveling device 4, and the cab 7 is installed on the driving device. 3 on. The loading part 1 is installed under the front part of the main engine. The loading part 1 is mainly composed of a scraping plate 102 and two star wheels 101 symmetrically arranged on the scraping plate 102. The tail end of the scraping plate 102 is connected with the driving device 3. The two sides of the car are connected with the loading part lifting cylinder 2 fixed on the main frame, and the loading part 1 can swing up and down + 300-200mm around the pin shaft. The loading part 1 is hingedly installed on the front end of the driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com