Method for preparing organic polymer absorbent material using post treatment

A technology of organic polymers and hygroscopic materials, applied in the field of hygroscopic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

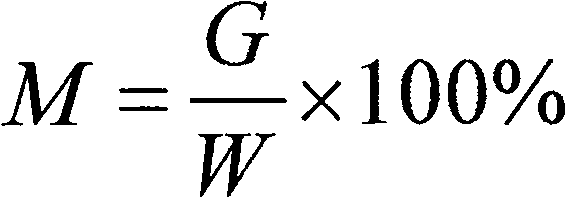

Image

Examples

Embodiment 1

[0015] Weigh 0.3 g of glycerol, dissolve it in 50 g of ethanol, and stir evenly; weigh 50 g of hexane, pour the hexane into the ethanol solution, and stir evenly to obtain a post-treatment liquid for the organic polymer hygroscopic material.

[0016] Weigh 200 grams of cross-linked sodium polyacrylate with a 500 ml beaker, pour the prepared organic polymer hygroscopic material post-treatment solution into the beaker, stir to mix them evenly, and place them for 12 hours; Dry within 4 hours. The obtained modified organic polymer hygroscopic material has a hygroscopic capacity of 54% at 30°C and a relative humidity of 50%, and a hygroscopic capacity of 30% before treatment.

Embodiment 2

[0018] Weigh 1 gram of ethylene glycol, dissolve it in 30 grams of ethanol, and stir evenly; weigh 70 grams of hexane, pour the hexane into the ethanol solution, and stir evenly to obtain a post-treatment liquid for organic polymer hygroscopic materials.

[0019] Weigh 200 grams of cross-linked sodium polyacrylate in a 500-ml beaker, pour the prepared organic polymer moisture-absorbing material post-treatment solution into the beaker, stir to mix them evenly, and place them for 15 hours; Dry within 6 hours. The obtained modified organic polymer hygroscopic material has a hygroscopic capacity of 57% at 30°C and a relative humidity of 50%, and a hygroscopic capacity of 30% before treatment.

Embodiment 3

[0021] Weigh 1 gram of glycerol, dissolve it in 40 grams of ethanol, and stir evenly; weigh 60 grams of hexane, pour the hexane into the ethanol solution, and stir evenly to obtain a post-treatment liquid for organic polymer hygroscopic materials.

[0022] Weigh 200 grams of cross-linked sodium polyacrylate in a 500-ml beaker, pour the prepared organic polymer moisture-absorbing material post-treatment solution into the beaker, stir to mix them evenly, and place them for 15 hours; Dry within 6 hours. The obtained modified organic polymer hygroscopic material has a hygroscopic capacity of 56% at 30°C and a relative humidity of 50%; the hygroscopic capacity before treatment is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com