Copper-clad plate base material

A basic material, copper-clad laminate technology, applied in the field of test equipment, can solve problems such as thermal deformation and warpage, insufficient material flexibility, and affect the efficiency of automated production, so as to improve the internal performance and quality of the board, improve the flatness stability, and improve The effect of appearance ceiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The copper-clad laminate basic material formula of the present embodiment is as follows:

[0027] raw material name Original recipe (+TCPP) Alternative Flame Retardant 1 (590A) Alternative Flame Retardant 2 (590C) 055 60 - - 590A - 60 - 590C - - 60 SH 185 185 185 ES-1 506 506 506 016 130 130 130 Aluminum hydroxide 7.5 7.5 7.5 028 85.5 85.5 85.5

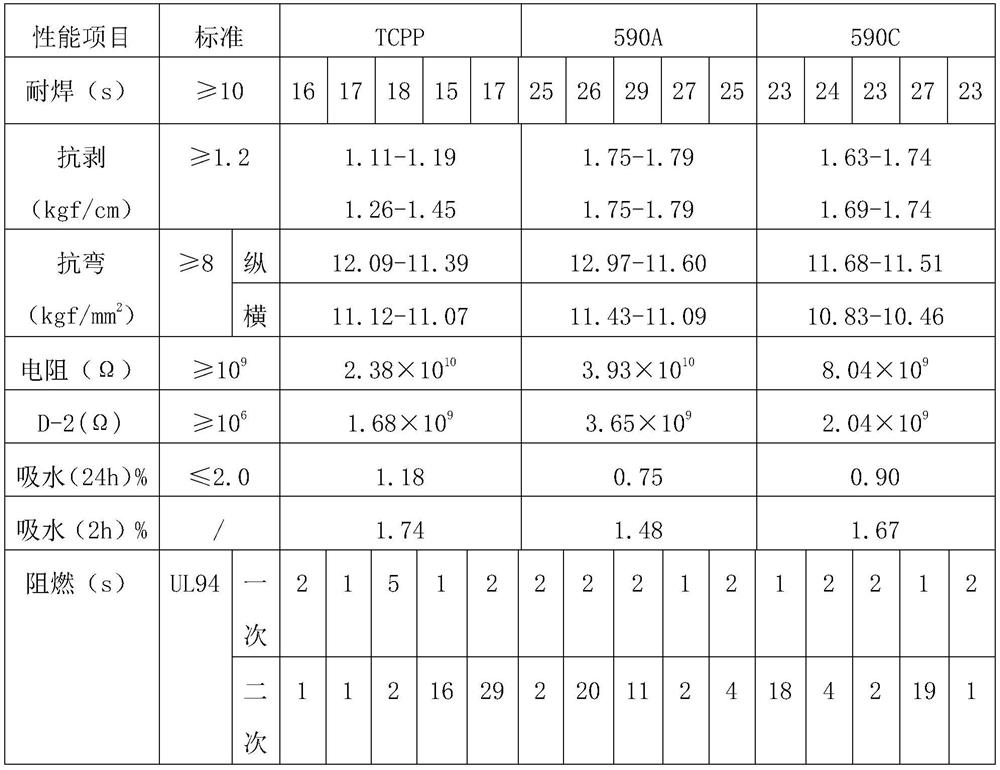

[0028] Use the above formula to prepare glue solution in the laboratory, respectively test the gel time to the qualified range, then manually glue and dry. The test gel time and the weight of the adhesive paper after drying are as follows:

[0029] TCPP Alternative Flame Retardant 1 (590A) Alternative Flame Retardant 2 (590C) Gel time / s 153 155 157 Glue weight / g 268.0 273.5 259.0

[0030] Among them, SH and ES-1 are two different phenolic resins, 016 is epoxy resin, 028 is a peptizer, and two new flame retardants, 5...

Embodiment 2

[0040] The copper-clad laminate basic material formula of the present embodiment is as follows:

[0041] raw material name Original recipe (+TPP) Alternative Flame Retardant 1 (590A) Alternative Flame Retardant 2 (590C) SH 308.5 308.5 308.5 ES-1 308.5 308.5 308.5 JP-050 140.6 - - 590A - 140.6 - 590C - - 140.6 015 81.2 81.2 81.2 076 10 10 10 W100 65 65 65 028 86.2 86.2 86.2

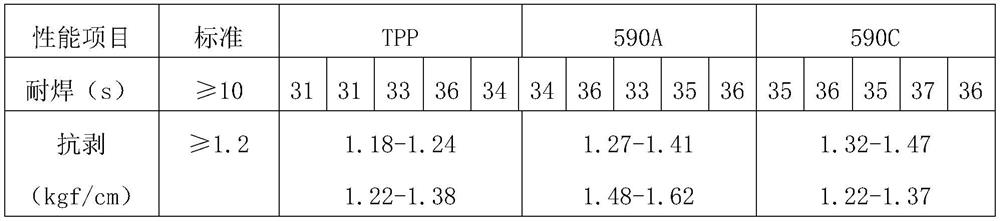

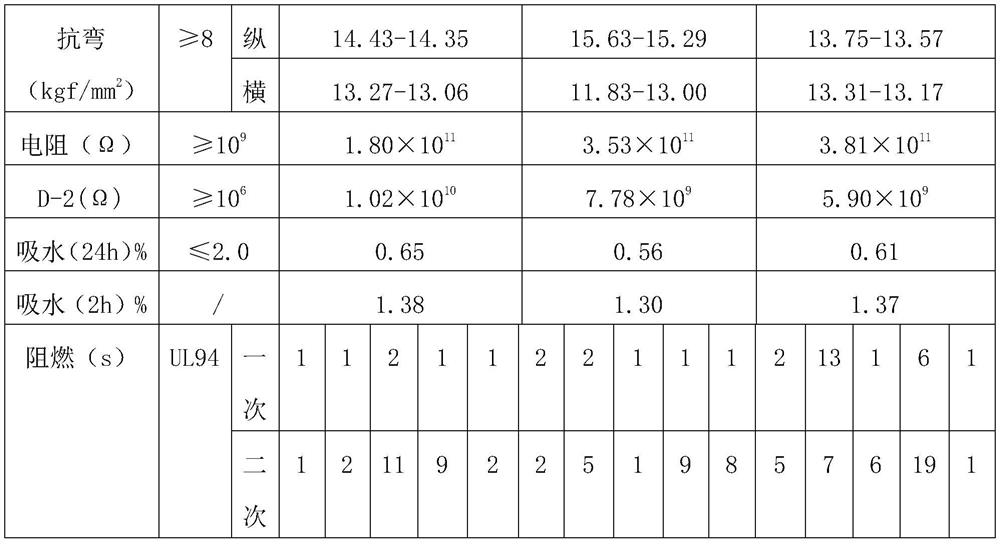

[0042] Use the above formula to prepare glue solution in the laboratory, respectively test the gel time to the qualified range, then manually glue and dry. The test gel time and the weight of the adhesive paper after drying are as follows:

[0043] TPP Alternative Flame Retardants 1 Alternative Flame Retardants 2 Gel time / s 197 187 192 Glue weight / g 281.2 279.6 271.2

[0044] Among them, SH and ES-1 are two different phenolic resins, 015 and 076 are epoxy resins, W100 is a water-soluble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com