Air-carrying tritium-containing wastewater system with condensation dehumidification function

An air and carrier tape technology, applied in air heaters, refrigerators, refrigeration and liquefaction, etc., can solve the problems of lack of environmental adaptability, inability to adjust emissions, limitation of carrier air moisture absorption capacity, etc., to achieve good promotion value and Application prospect, utilization of renewable energy, effect of improving air-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

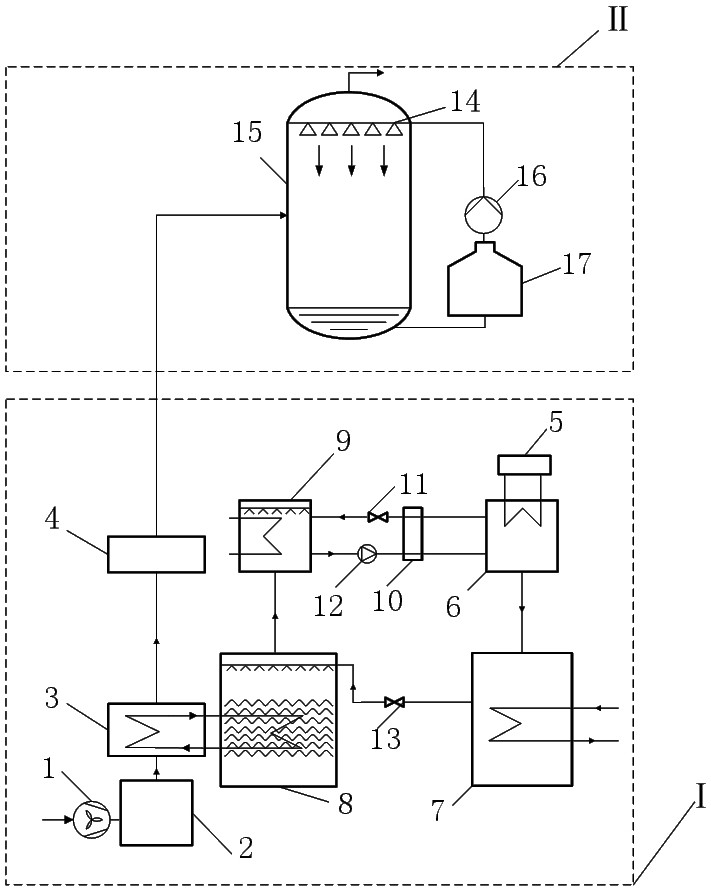

[0033] see figure 1 , an air-carrying tritium-containing wastewater system with condensation dehumidification includes an absorption refrigeration condensation dehumidification device and a high-efficiency micro-mist humidification device.

[0034] Absorption refrigeration condensation dehumidification device includes fan 1, dust removal chamber 2, condensation dehumidifier 3, air duct heater 4, heat source 5, generator 6, condenser 7, evaporator 8, absorber 9, intermediate heat exchanger 10, The first throttle valve 11, the first circulation pump 12 and the second throttle valve 13;

[0035] The micro-mist humidification device includes a micro-mist multi-nozzle array 14 , a micro-mist humidification tower 15 , a liquid storage tank 16 and a second circulation pump 17 .

[0036] The specific connection relationship of each device is detailed as follows:

[0037] The air duct inlet of the fan 1 is connected to the outdoor environment, the air duct outlet of the fan 1 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com