A method for preparing composite humidity-controlling material by modifying inorganic powder with silica-alumina gel

A humidity-regulating material and inorganic powder technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as slow moisture absorption and dehumidification, poor dehumidification performance, difficult to analyze moisture, etc., and achieve an increase in equilibrium moisture content , Improving the speed of moisture absorption and desorption, and the effect of high moisture absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

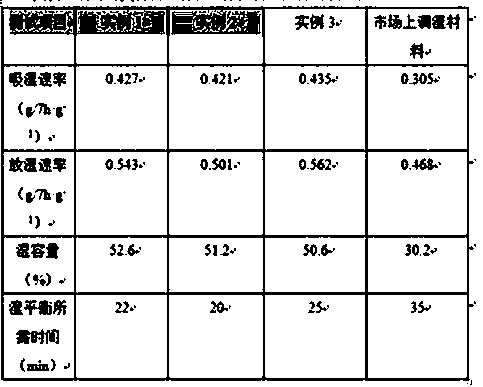

example 1

[0020] In parts by weight, 100 parts of perlite, 80 parts of calcium silicate, 30 parts of zeolite, 120 parts of 30-mesh corn stalk particles, 150 parts of sodium chloride, 80 parts of calcium chloride, 50 parts of potassium carbonate and 40 parts of Magnesium chloride, stir and mix evenly to obtain a mixture, mix the mixture with deionized water according to the mass ratio of 1:10, and heat to 60°C, stir and mix for 50min and then filter to obtain a filter residue, put the filter residue in an oven, at 100°C Dry for 10 hours to obtain the dried filter residue, put the dried filter residue into a ball mill and pass through a 240-mesh sieve to obtain a modified mixed powder; put the modified mixed powder into a carbonization furnace, and heat it under a nitrogen atmosphere at 10°C / Min heating rate was raised to 700°C, heat-preserved and carbonized for 100 minutes, cooled to room temperature and discharged, and the carbonized powder was collected; according to the mass ratio of ...

example 2

[0022] In parts by weight, 50 parts of perlite, 60 parts of calcium silicate, 20 parts of zeolite, 100 parts of 20 mesh corn stalk particles, 120 parts of sodium chloride, 60 parts of calcium chloride, 30 parts of potassium carbonate and 20 parts of Magnesium chloride, stirred and mixed evenly to obtain a mixture, according to the mass ratio of 1:10, mixed the mixture with deionized water, and heated to 50 ° C, stirred and mixed for 30 minutes and filtered to obtain a filter residue, put the filter residue in an oven, at 100 ° C Dry for 8 hours to obtain the dried filter residue, put the dried filter residue into a ball mill and pass through a 200-mesh sieve to obtain a modified mixed powder; put the modified mixed powder into a carbonization furnace, and heat it at 5 ° C / The heating rate was raised to 650°C at a heating rate of 60 minutes. After 60 minutes of heat preservation and carbonization, it was cooled to room temperature and discharged, and the carbonized powder was ...

example 3

[0024]In parts by weight, 70 parts of perlite, 70 parts of calcium silicate, 25 parts of zeolite, 110 parts of 25 mesh corn stalk particles, 130 parts of sodium chloride, 70 parts of calcium chloride, 40 parts of potassium carbonate and 30 parts of Magnesium chloride, stirred and mixed evenly to obtain a mixture, according to the mass ratio of 1:10, mixed the mixture with deionized water, and heated to 55 ° C, stirred and mixed for 40 minutes and then filtered to obtain a filter residue, put the filter residue in an oven, at 110 ° C Dry for 9 hours to obtain the dried filter residue, put the dried filter residue into a ball mill and pass through a 220-mesh sieve to obtain a modified mixed powder; put the modified mixed powder into a carbonization furnace, and heat it at 7 ° C / Min heating rate was raised to 670°C, heat preservation and carbonization for 70 minutes, cooling to room temperature and discharging, and collecting carbonized powder; according to the mass ratio of 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com