Preparation method of safe and efficient humidity-controlling material

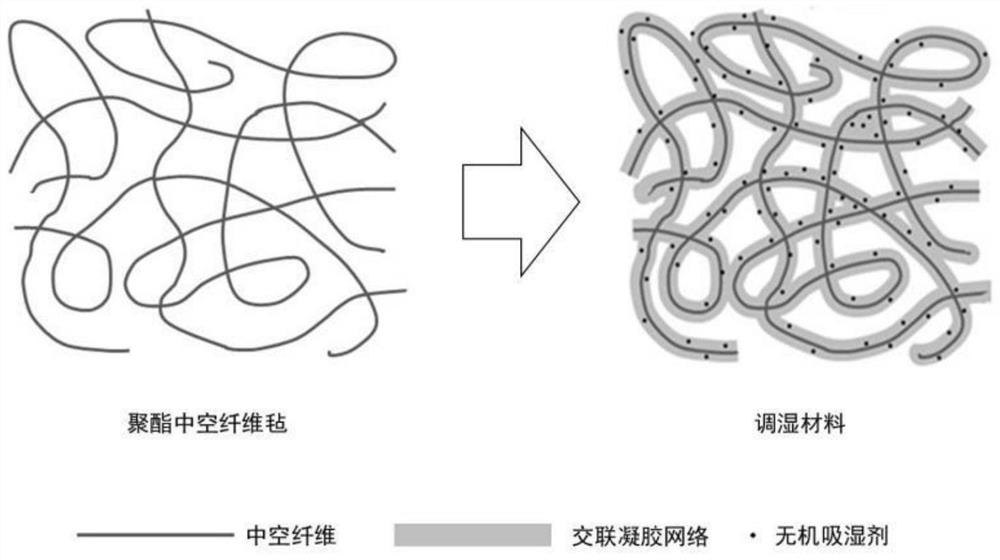

A moisture-conditioning material and high-efficiency technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of easy outflow of liquefied hydrated water, insufficient moisture absorption capacity of moisture-conditioning materials, etc., and achieve excellent moisture absorption capacity and large loading capacity. , the effect of large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The polyester hollow fiber mat containing 10% EHDPET was treated at 100° C. for 2 hours with 10 wt % sodium hydroxide aqueous solution, and washed with water. Prepare an aqueous solution containing 45wt% lithium chloride, 10wt% low molecular weight sodium polyacrylate and 1wt% glycerin, then add hydrochloric acid to convert 15% sodium carboxylate in the system into carboxylic acid. Immerse the treated polyester hollow fiber felt in the above aqueous solution for 10 minutes, take it out and dry it at 110°C for 8 hours, and esterification reaction occurs simultaneously at the drying temperature to form carboxylated polyester fiber / sodium polyacrylate / multi-component An integrated cross-linked gel network of alcohols.

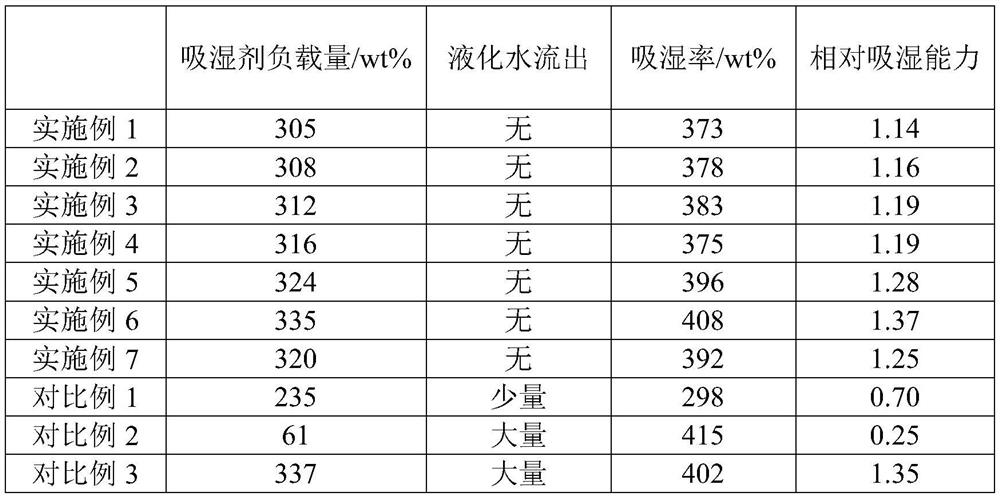

[0032] Weigh the humidity-conditioning material prepared by the above-mentioned process, and calculate the loading capacity of the polyester hollow fiber felt to the hygroscopic agent; then place the humidity-conditioning material in a closed environment wi...

Embodiment 2

[0034] The polyester hollow fiber mat containing 10% EHDPET was treated at 100° C. for 2 hours with 10 wt % sodium hydroxide aqueous solution, and washed with water. Prepare an aqueous solution containing 45wt% lithium chloride, 10wt% low molecular weight sodium polyacrylate and 2wt% ethylene glycol, and then add hydrochloric acid to convert 15% of sodium carboxylate in the system into carboxylic acid. Immerse the treated polyester hollow fiber mat in the above aqueous solution for 10 minutes, take it out and dry it at 110°C for 8 hours, and esterification reaction occurs simultaneously at the drying temperature to form carboxylated polyester fiber / sodium polyacrylate / multi-component An integrated cross-linked gel network of alcohols. The performance test method of the humidity-conditioning material is shown in Example 1, and the results are shown in Table 1.

Embodiment 3

[0036]The polyester hollow fiber mat containing 15% EHDPET was treated at 100° C. for 2 hours with 10 wt % sodium hydroxide aqueous solution, and washed with water. Prepare an aqueous solution containing 45wt% lithium chloride, 10wt% low molecular weight sodium polyacrylate and 2wt% ethylene glycol, and then add hydrochloric acid to convert 15% of sodium carboxylate in the system into carboxylic acid. Immerse the treated polyester hollow fiber felt in the above aqueous solution for 10 minutes, take it out and dry it at 110°C for 8 hours, and esterification reaction occurs simultaneously at the drying temperature to form carboxylated polyester fiber / sodium polyacrylate / multi-component An integrated cross-linked gel network of alcohols. The performance test method of the humidity-conditioning material is shown in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com