Silastic coloring mater match and preparation

A coloring masterbatch and silicone rubber technology, which is applied in the field of silicone rubber coloring masterbatch, can solve the problems of not needing full coloring, difficult color change, shortened production cycle, etc., and achieves convenient color change, good processing performance and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

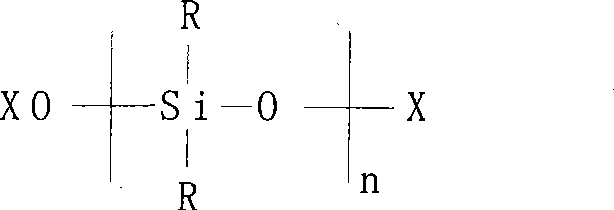

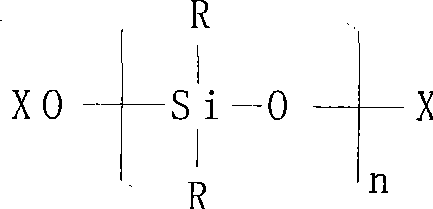

Method used

Image

Examples

Embodiment 1

[0034] The weight ratio of silicone rubber coloring masterbatch is as follows:

[0035] Silicone rubber: methyl silicone rubber, methyl vinyl silicone rubber, methylphenyl silicone rubber, fluorosilicone rubber or nitrile silicone rubber - 100 parts;

[0036] Reinforcing agent: fumed silica, precipitated silica or surface treated silica - 15 parts;

[0037] Structure control agent: diphenylsilanediol, methylphenyldimethoxysilane, methylphenyldiethoxysilane or dimethylhydroxypolysiloxane - 1 part;

[0038] Pigment: 120 parts.

Embodiment 2

[0040] The weight ratio of silicone rubber coloring masterbatch is as follows:

[0041] Silicone rubber: methyl silicone rubber, methyl vinyl silicone rubber, methylphenyl silicone rubber, fluorosilicone rubber or nitrile silicone rubber - 100 parts;

[0042] Reinforcing agent: fumed silica, precipitated silica or surface treated silica - 30 parts;

[0043] Structure control agent: diphenylsilanediol, methylphenyldimethoxysilane, methylphenyldiethoxysilane or dimethylhydroxypolysiloxane - 1 part;

[0044] Pigment: 135 parts.

Embodiment 3

[0046] The weight ratio of silicone rubber coloring masterbatch is as follows:

[0047] Silicone rubber: methyl silicone rubber, methyl vinyl silicone rubber, methylphenyl silicone rubber, fluorosilicone rubber or nitrile silicone rubber - 100 parts;

[0048] Reinforcing agent: fumed silica, precipitated silica or surface-treated silica—50 parts;

[0049] Structure control agent: diphenylsilanediol, methylphenyldimethoxysilane, methylphenyldiethoxysilane or dimethylhydroxypolysiloxane—2 parts;

[0050] Pigment: 145 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com