Well completion method of ground dipping uranium extracting process well

An in-situ leaching technology for uranium mining and process wells, which is applied in wellbore/well components, mining fluids, earth-moving drilling, etc. Efficiency and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

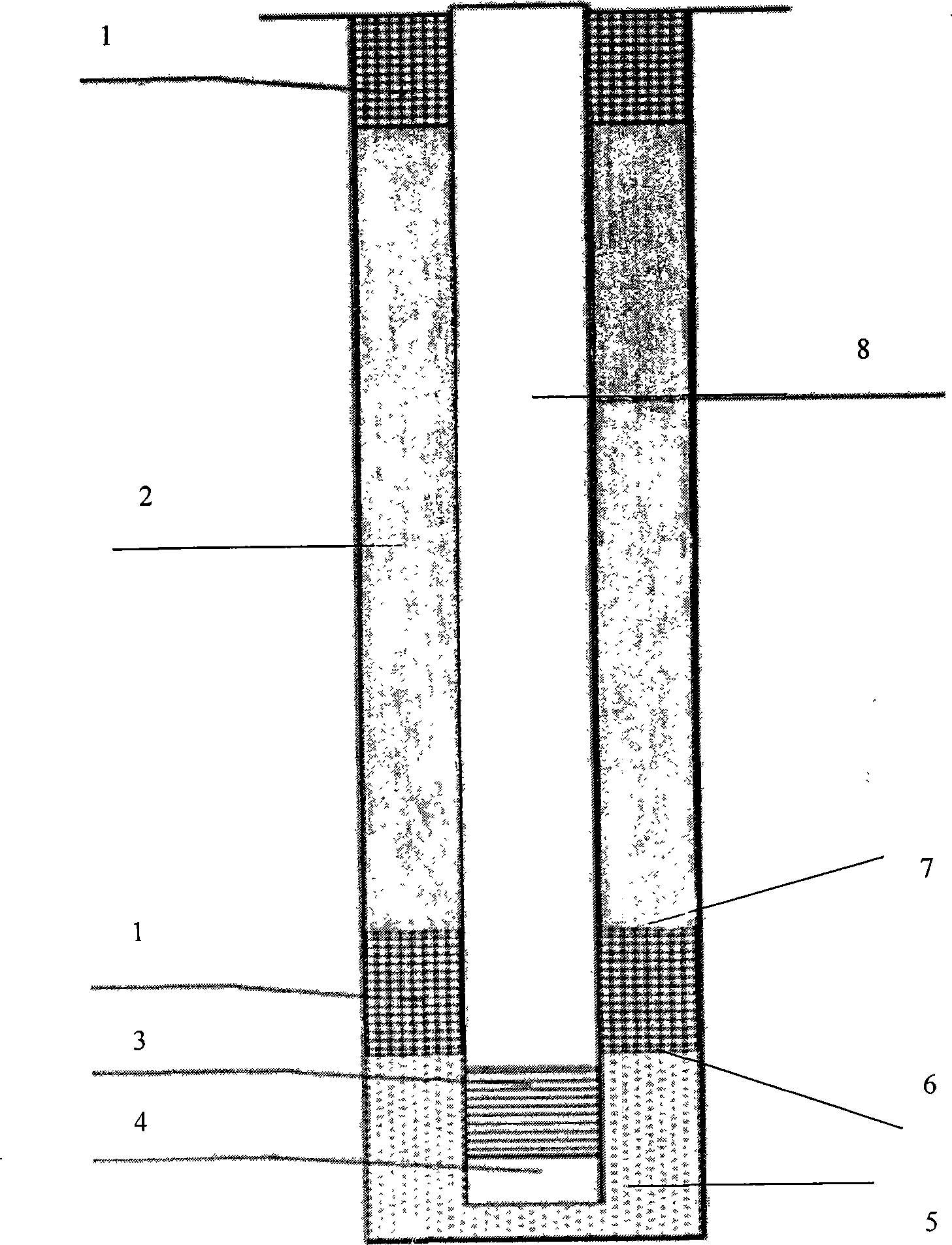

[0008] Completion method of in-situ leaching uranium mining process: the casing of the uranium mining process well is made of PVC material pipes, and the pipes are connected with screws, and PVC glue is evenly applied to ensure sealing and prevent layering; PVC ring-shaped skeleton screens are used The screen pipe replaces the screen-type screen pipe, which not only ensures the water passing area, but also helps to increase the recovery rate and is not easy to be blocked; there are iron rings at the upper and lower ends of the screen pipe, which is convenient to measure whether the position of the screen pipe is consistent with the ore seam, and is easy to Adjust the error to ensure the uniformity and direction of the screen, which can ensure that the screen is accurately placed in place, ensure the best water passage, and help improve the recovery efficiency. Pour cement plugs at the bottom of the sand settling pipe to prevent the cone at the bottom of the sand settling pipe f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com