Gear drive mechanism of rotating shaver

A technology of gear transmission mechanism and shaver, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc. It can solve the problems of gears not meshing normally, short service life, high production cost, etc., and achieve simplified manufacturing and assembly Process requirements, improve product quality, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

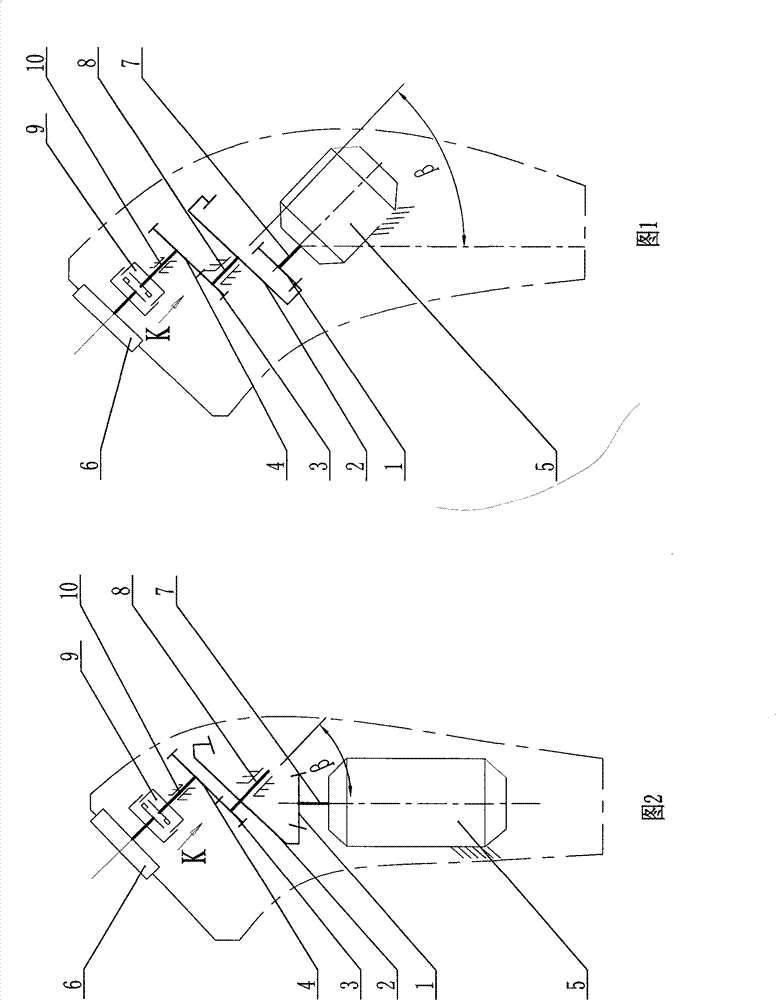

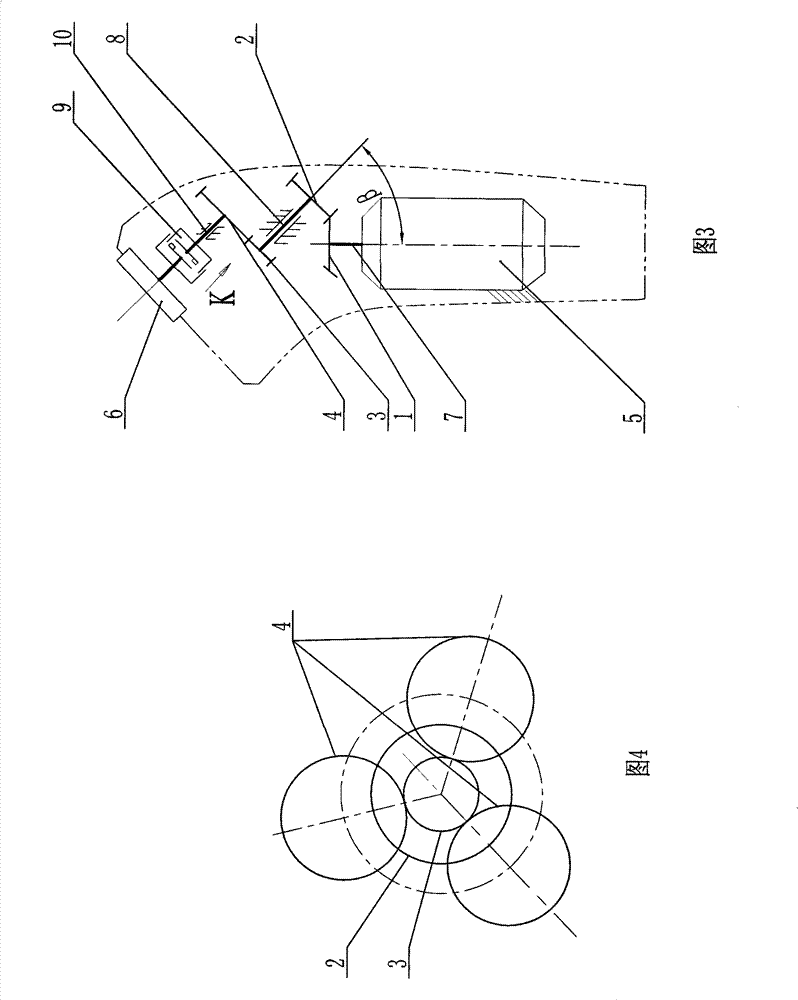

[0014] Specific embodiment 1: the gear transmission mechanism of the rotary shaver is to comprise the gear transmission mechanism between the driving gear installed on the motor shaft, at least one half coupling, the driving gear and the half coupling, the driving gear, the driving The gear transmission mechanism between the gear and the half-coupling is composed of at least one cylindrical bevel gear and several cylindrical gears. The sum of the included angles formed by the axis of the cylindrical bevel gear and the axis of the meshing cylindrical gear in each transmission stage is equal to the axis of the handle. (that is, the axis of the motor) and the angle requirements between the axis of the razor group. Cylindrical bevel gears are bevel gears that can mesh with involute cylindrical gears. The forming principle of the tooth profile is that under the condition that the two axes of the gear shaper and the bevel gear blank intersect and form a set angle, the involute gear i...

specific Embodiment 2

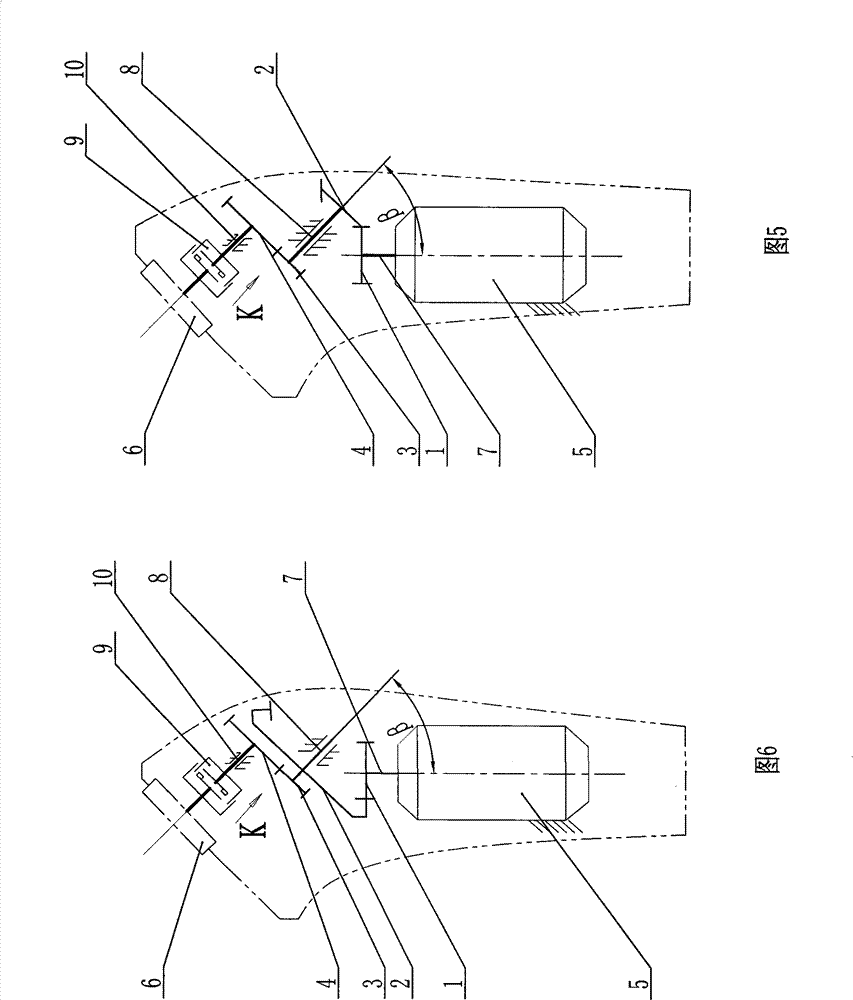

[0015] Specific embodiment 2: as Figure 6 As shown, the gear transmission mechanism of the rotary shaver is provided with a first driving gear 1, a first driven gear 2, a second driving gear 3 and three second driven gears 4, wherein the first driven gear The gear 2 adopts an inner cylindrical bevel gear, and its taper is determined by the angle β between the axis of the motor 5 and the razor group 6 axes. The first driving gear 1 adopts a cylindrical gear to be arranged on the motor shaft 7, and the first driven gear 2 and the second driving gear 3 form a duplex gear and are arranged at both ends of the first driven shaft 8, and the first driven shaft 8 and the The motor shaft 7 is installed obliquely, the angle is the angle between the two axes (that is, the set angle β) described in the tooth profile forming principle of the cylindrical bevel gear, the axis of the motor 5 is vertically arranged, along the axis of the first driven shaft 8 Direction The first driven wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com