Motor device and motor control speed system

A motor and control device technology, applied in the direction of a single motor speed/torque control, electronic commutator, etc., can solve the problems of complex circuit structure, component cost, assembly man-hours and device failure rate effects, and achieve a simplified circuit design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A motor device and a motor speed control system according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same component symbols.

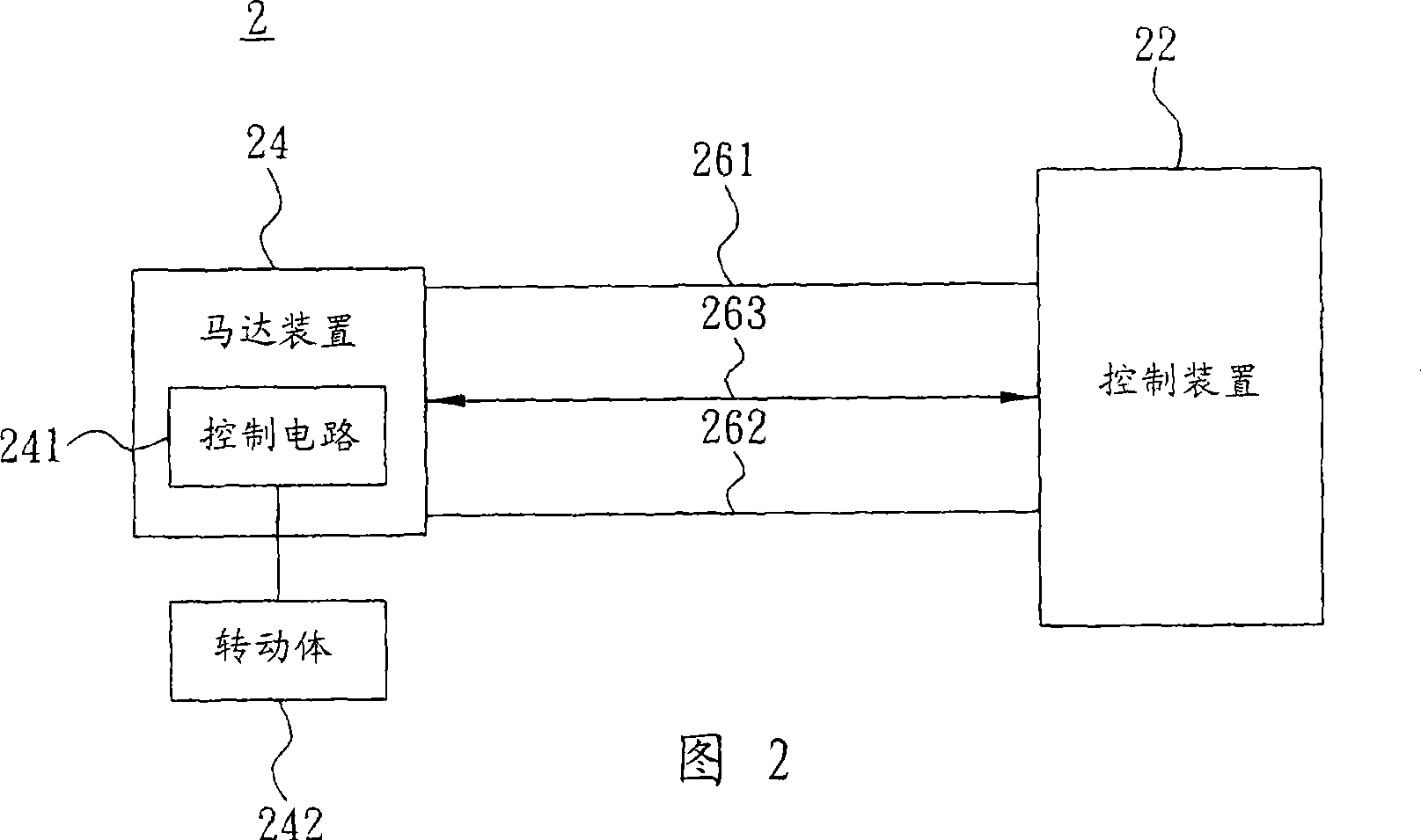

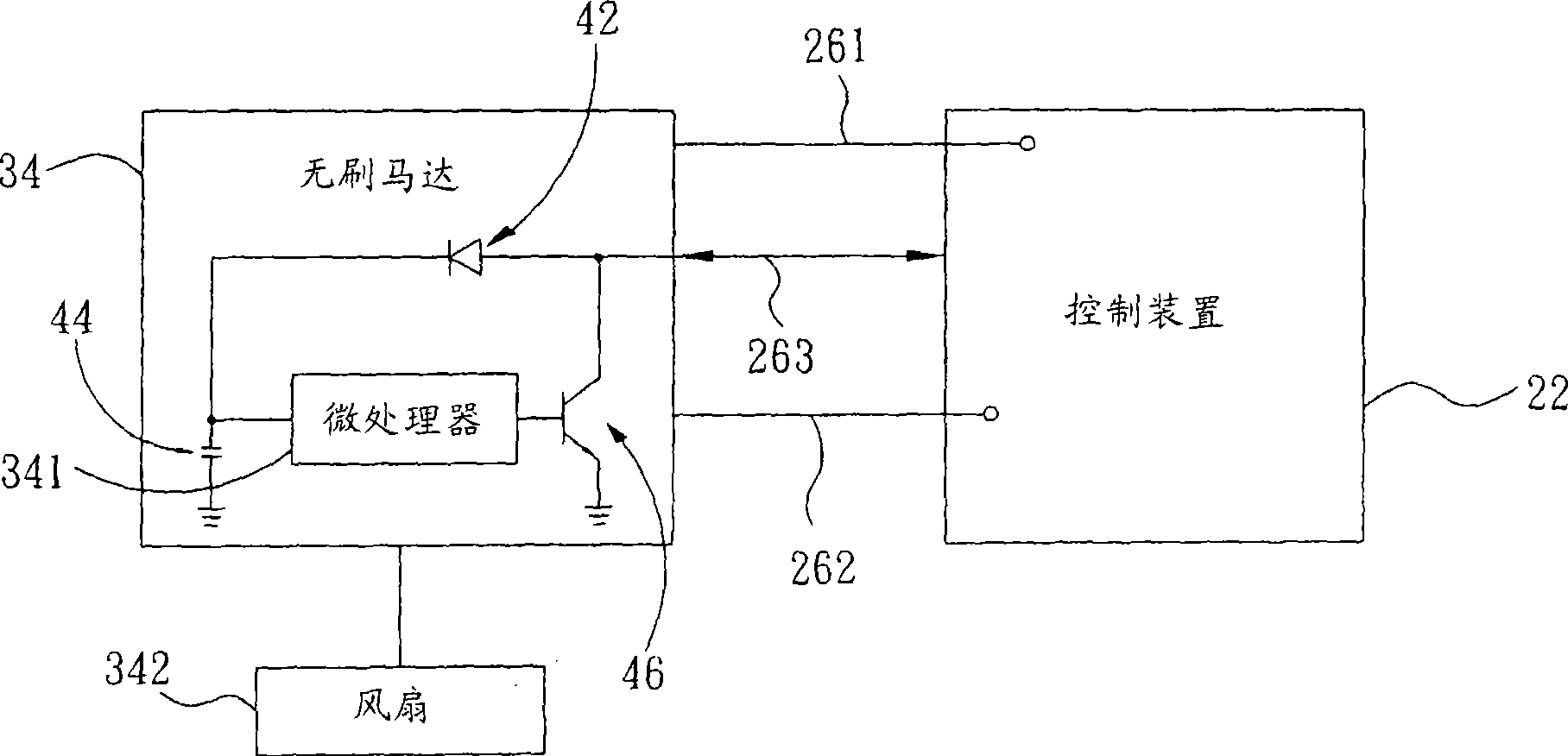

[0025] Please refer to FIG. 2, which is a schematic block diagram of a motor speed control system disclosed in the present invention. The motor speed control system 2 includes a control device 22, a motor device 24, and a device coupled to the control device 22 and the motor device 24. There is a positive power signal line 261 , a negative power signal line 262 and a feedback / speed control signal line 263 . Therefore, the control device 22 controls the motor device 24, and further enables the motor device 24 to drive the action of the rotating body 242 connected thereto. At the same time, the motor device 24 also feeds back the rotation state of the rotating body 242 to the control device 22, so that the control device 22 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com