Terminal landing speed control system of elevator

A technology for controlling the system and layer speed, applied in elevators, transportation and packaging, etc., can solve the problems of complex car position detection and other problems, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

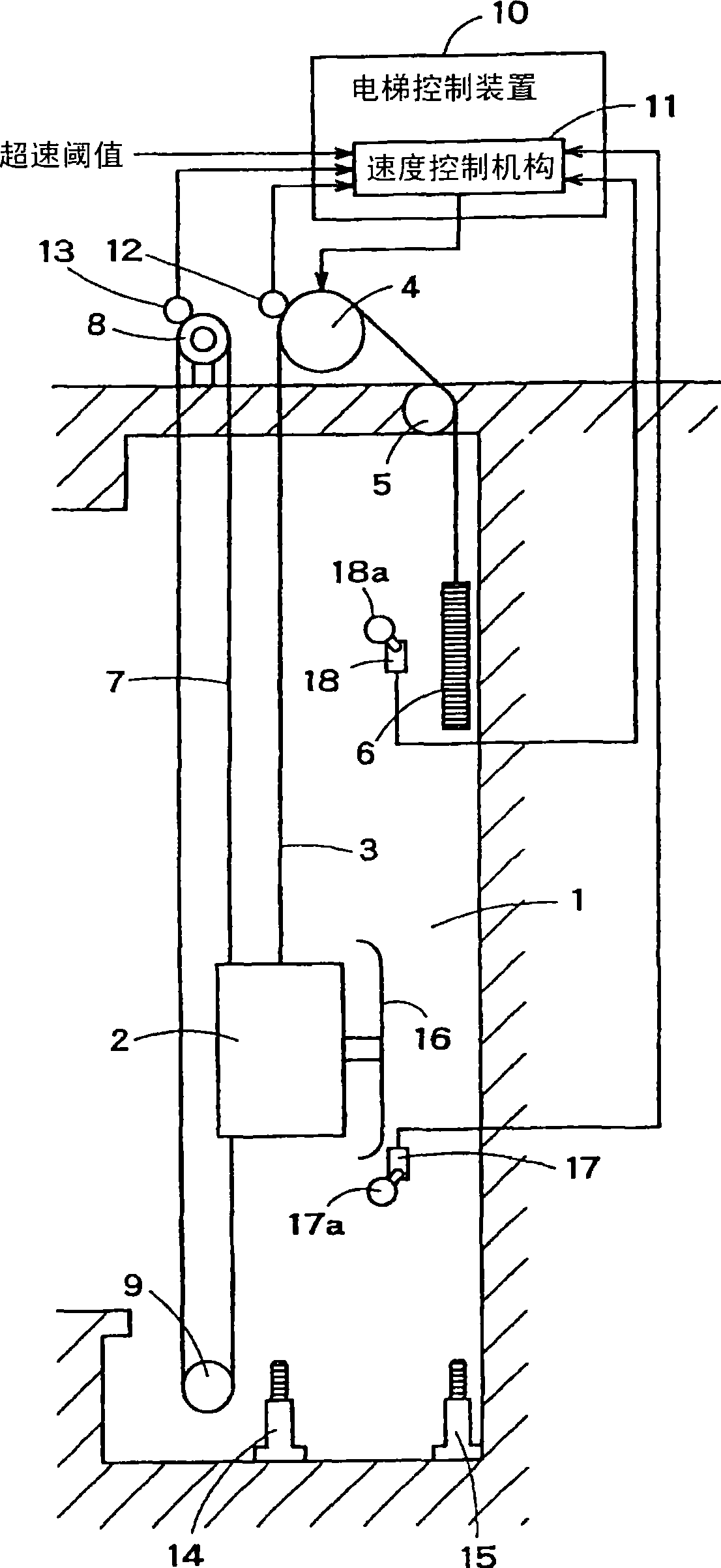

[0022] figure 1 It is a configuration diagram of an elevator terminal floor speed control system according to an embodiment of the present invention. A lift passage 1 is formed in a building, and a car 2 can move up and down in the lift passage 1 . One end side of a main rope 3 is attached to the car 2 . The middle portion of the main rope 3 is wound around a hoist 4 installed in a machine room, and the other end thereof is attached to a counterweight 6 via a deflector pulley 5 .

[0023] On the other hand, one end side and the other end side of the adjuster rope 7 are attached to the car 2 . The adjuster rope 7 is wound through an adjuster 8 and an adjuster pulley 9 .

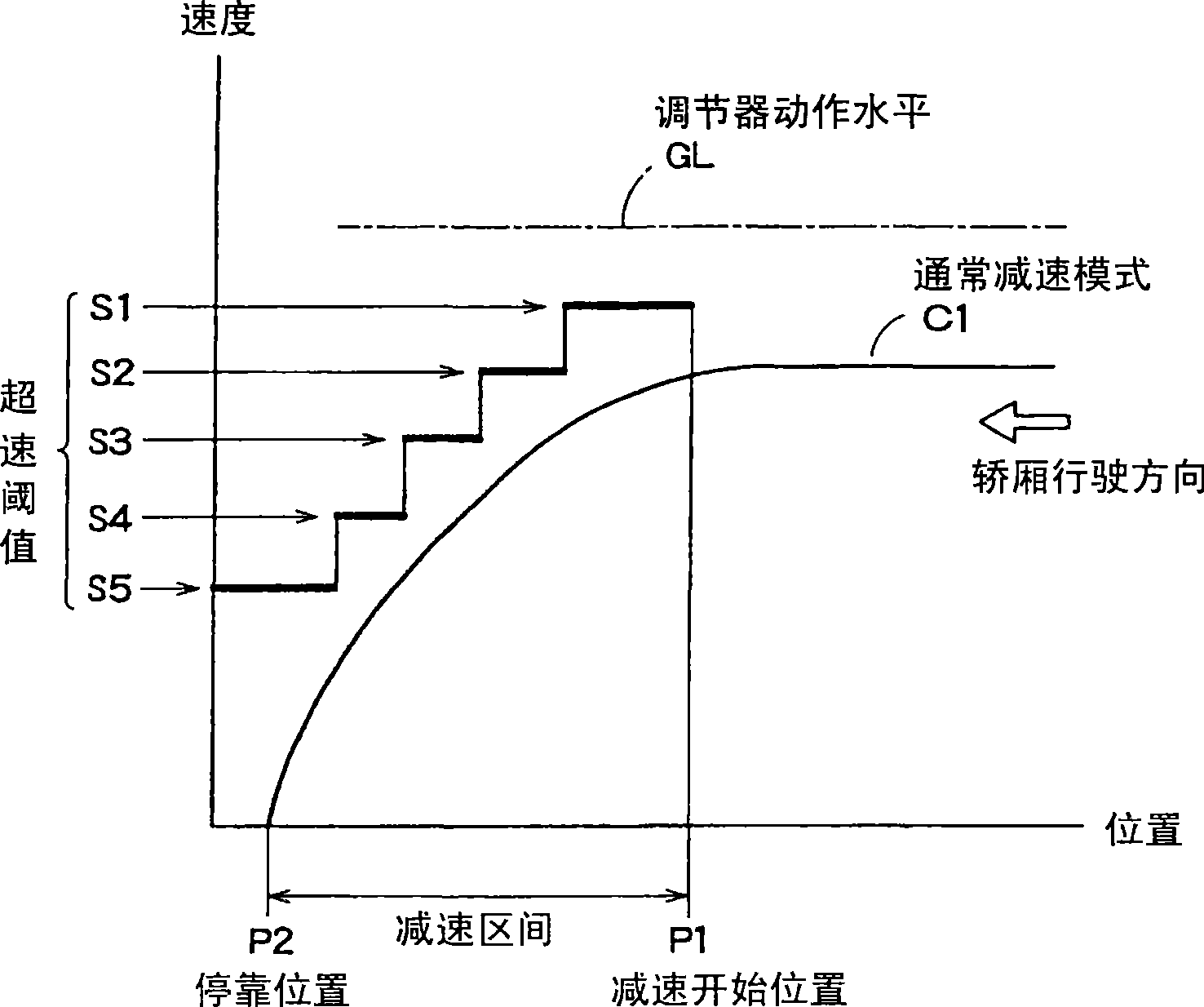

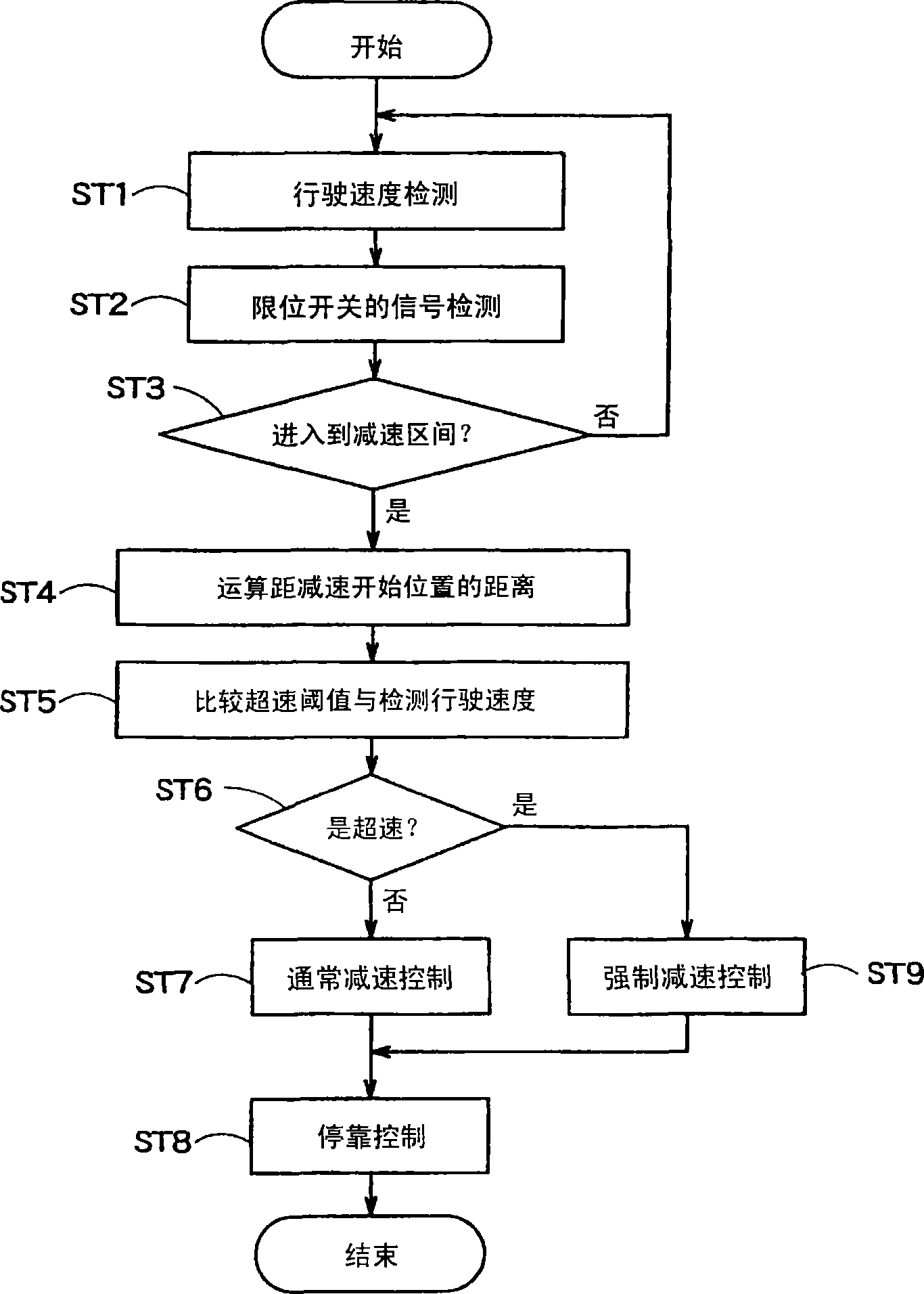

[0024] The hoist 4 is controlled by a speed control mechanism 11 provided in the elevator control device 10 . The speed control mechanism 11 inputs the detected driving speed from the speed detectors 12, 13 respectively installed on the hoist 4 and the regulator 8, and compares it with the preset overspeed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com