Octopus cultivation cage

A technology for breeding cages and octopuses, applied in the field of octopus breeding cages, can solve the problems of difficulty in making major breakthroughs in artificial breeding of octopus, small breeding scale, low unit output, etc., and achieves convenient daily feeding and observation, long service life, and processing simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

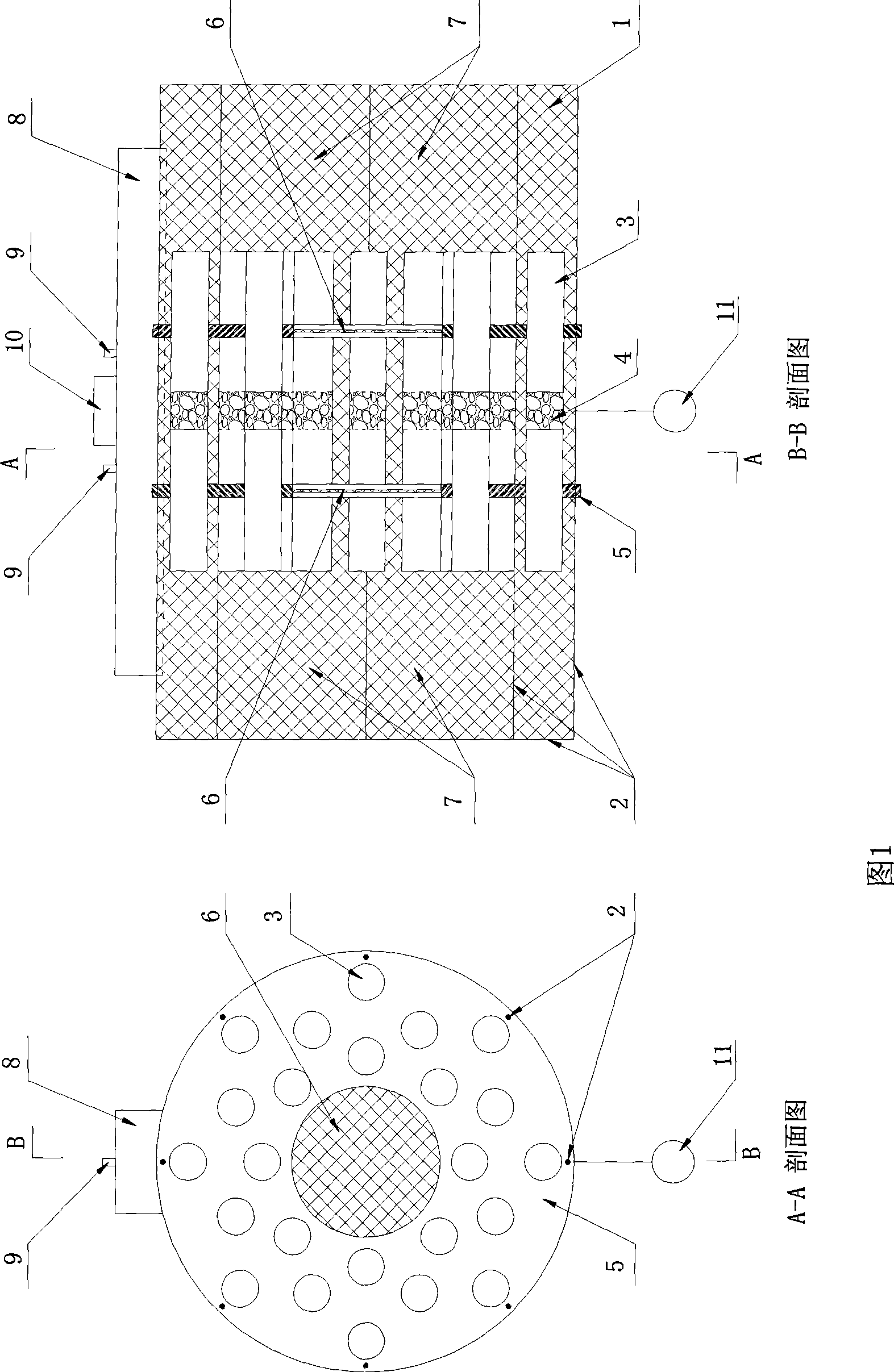

[0015] As shown in accompanying drawing 1, a kind of octopus breeding cage is cylindrical as a whole, about 1.0m long, about 30~50cm in diameter, and steel bar frame (2) is welded by 8 straight steel bars and two steel bar rings, In order to avoid severe seawater corrosion, the steel frame should be treated with appropriate anti-corrosion treatment. There are two plastic circular plates (5), which are horizontally fixed on the steel frame (2), and the plastic circular plate (5) and the steel frame (2) form the skeleton structure of the breeding cage together. The maintenance net (1) wraps the periphery of the skeleton. The plastic circular plate (5) is drilled with some circular holes, and the polyvinyl chloride pipe (3) passes through the front and rear two plastic circular plates (5) longitudinally through the circular holes to provide a shelter for the octopus. The diameter of the polyvinyl chloride pipe (3) is 5cm, but in order to meet the needs of the octopus for the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com