Shrimp and crab farming apparatus

A technology of shrimp and crab and water pipe, which is applied in fish farming, application, animal husbandry, etc. It can solve the problems of limited production pond area, broken limbs and few legs, easy to fight, etc., to increase the amount of shrimp and crab breeding and reduce the temperature Effects of change and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

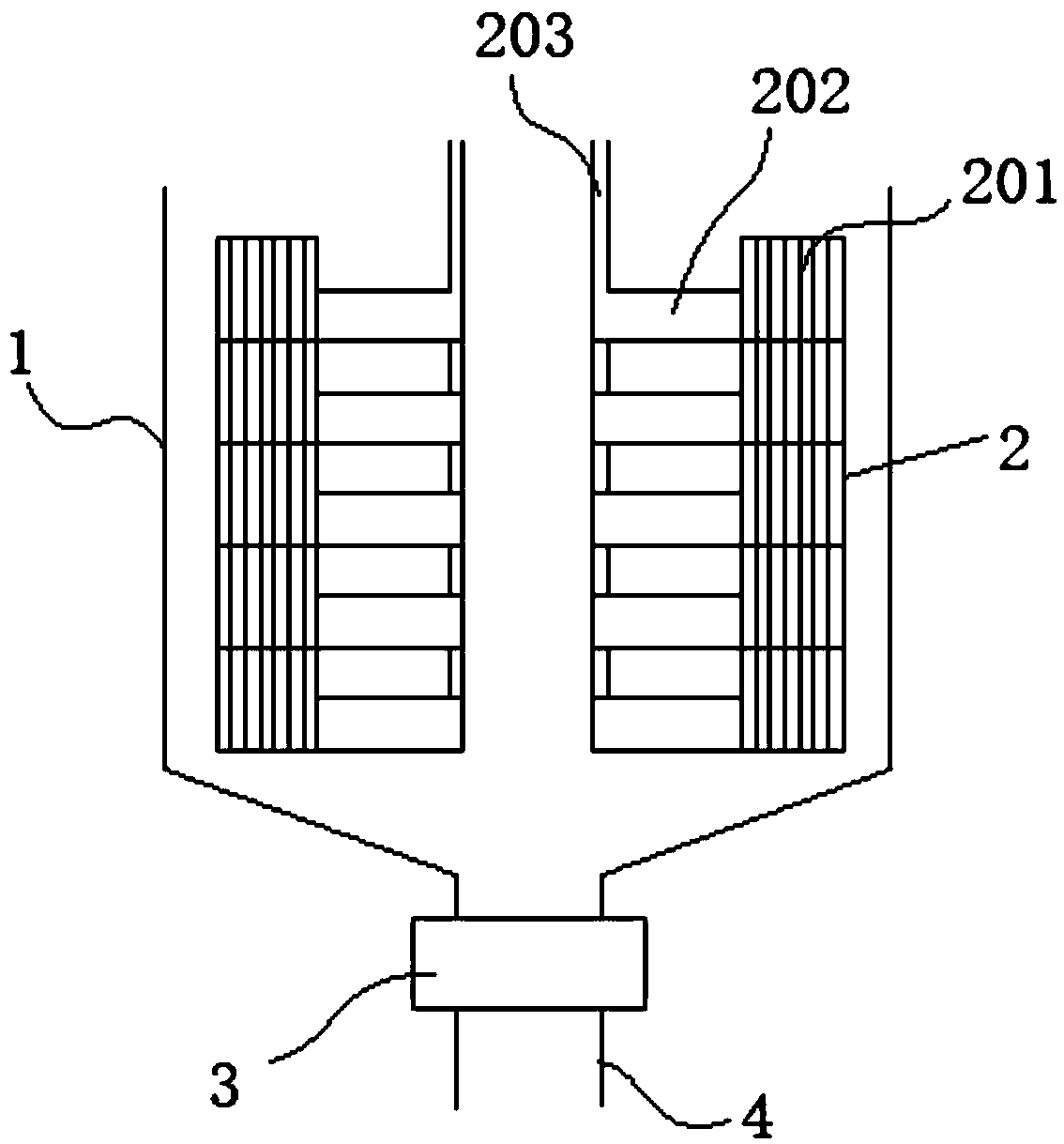

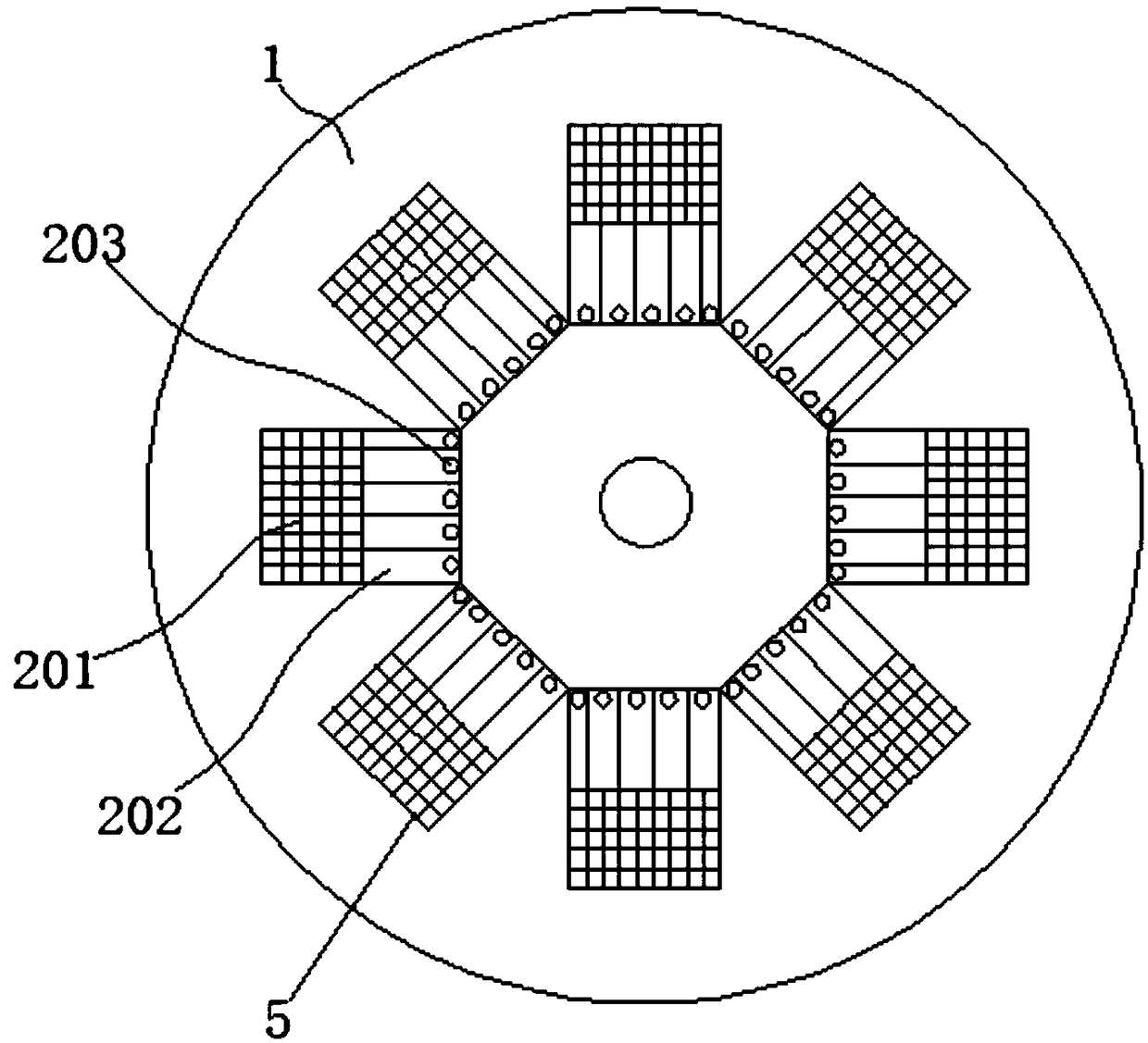

[0031] Such as figure 1 , figure 2 and image 3 As shown, a shrimp and crab breeding device includes at least one culture tube 1 with an open top, the bottom of the culture tube 1 has an outlet pipe 4 communicating with the inside of the culture cylinder 1, and a drainage control valve 3 is installed on the outlet pipe 4;

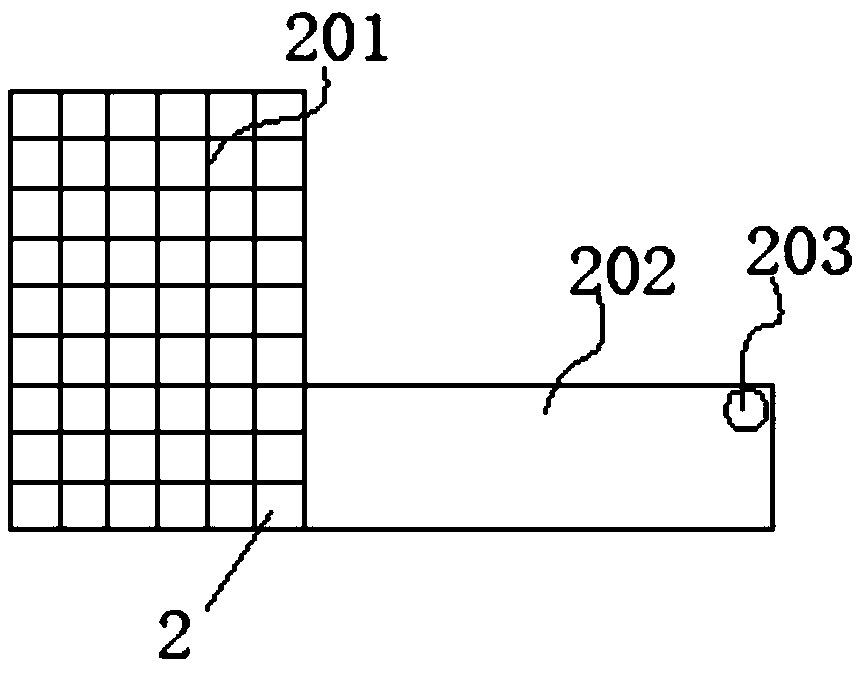

[0032] The culture tube 1 is provided with at least one pipe cage pavilion group 5, and each pipe cage pavilion group 5 is composed of a plurality of vertically stacked pipe cage pavilions 2, and the pipe cage pavilion 2 includes a cage pavilion 201, a habitat pipe 202 and a feeding pipe 203, one end of the habitat pipe 202 is horizontally connected to the cage pavilion 201, and the other end is connected to one end of the feeding pipe 203, and the other end of the feeding pipe 203 extends to the top opening of the culture tube 1, and the adjacent cage pavilions 201 are vertically stacked on each other; Each tube cage pavilion group 5 is arranged around ...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 and 4As shown, four breeding cylinders 1 are arranged in parallel, and also include a water circulation sterilization filtration system. The input end of the water circulation sterilization filtration system is connected to the end of the water outlet pipe 4 away from the cultivation cylinder 1, and the output end of the water circulation sterilization filtration system is connected to the cultivation cylinder through the return pipe 15. 1. After opening the drainage control valve 3, the water in the cultivation cylinder 1 enters the water circulation sterilization and filtration system through the outlet pipe 4, performs circulation sterilization and filtration, and then flows back into the cultivation cylinder 1 through the return pipe 15; the water circulation sterilization and filtration system includes installation in sequence A microfilter 7 on the water pipe 6, a protein separator 9, a biochemical filter box 12 and an u...

Embodiment 3

[0038] On the basis of Example 1 and Example 2, as figure 1 and Figure 5 As shown, it also includes a sedimentation tank 19, the sedimentation tank 19 has a water inlet and a water outlet, and the water inlet is connected to one end of the water pipe 6 near the microfiltration machine 7 through a water diversion pipe 18, and a valve A17 is installed on the water diversion pipe 18, and the water passing pipe 6 is close to A valve B16 is installed at one end of the microfiltration machine 7, after the joint of the water diversion pipe 18 and the water passing pipe 6; the water outlet is connected to the end of the water pipe 6 near the ultraviolet disinfection chamber 13 through the return pipe 20, and the valve C21 is installed on the return pipe 20 A valve D22 is installed at the position before the connection between the backflow pipe 20 and the water pipe 6 near one end of the ultraviolet disinfection chamber 13 through the water pipe 6 .

[0039] Use method: Put the shrim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com