Steel box-concrete combined box plate arch structure and construction method thereof

A construction method, steel box arch technology, applied in the direction of arch bridges, erection/assembly bridges, bridge materials, etc., can solve the problems of complex construction technology, large structural deformation, poor safety, etc., and achieve good comprehensive technical and economic benefits, good strength And the effect of anti-deformation ability and reliable connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

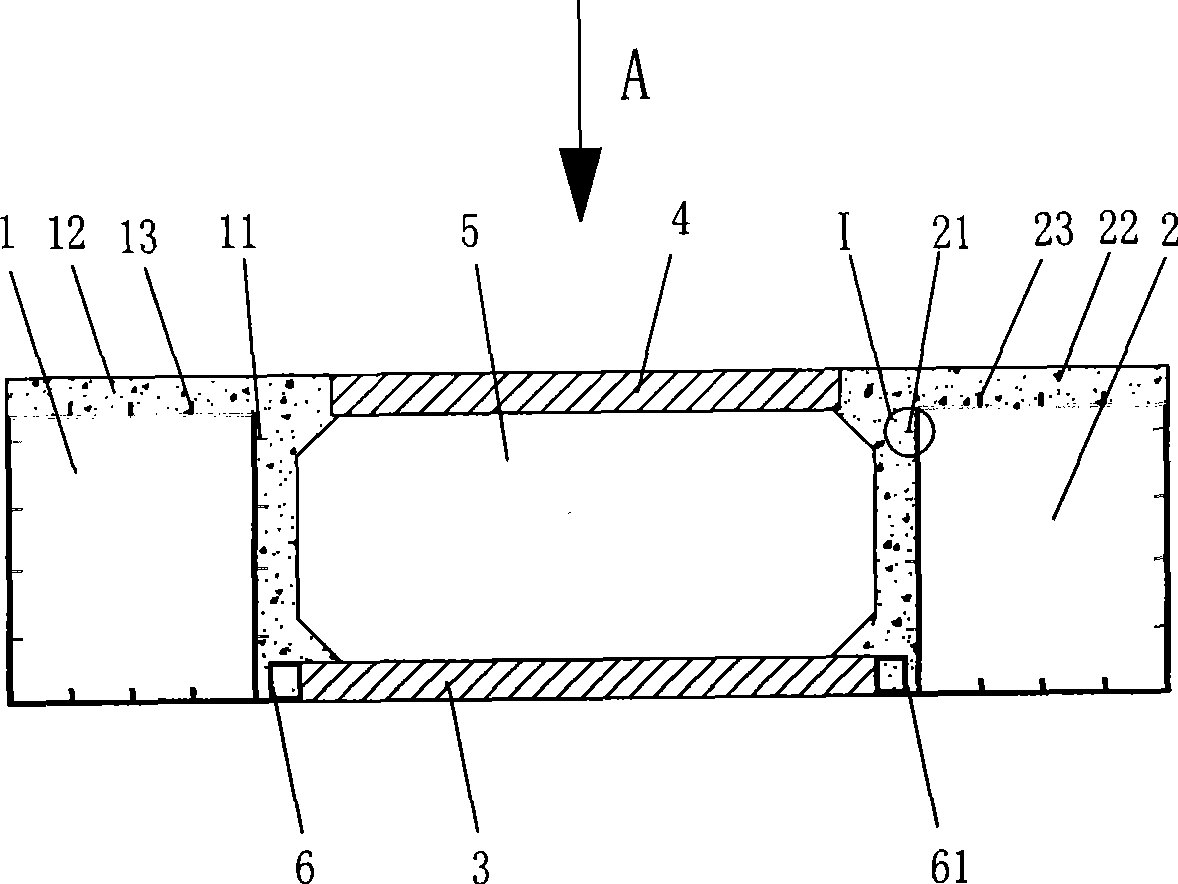

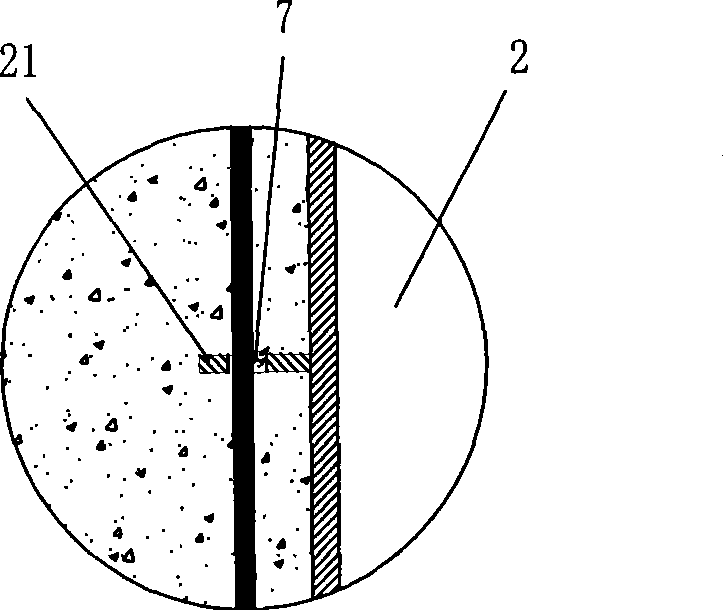

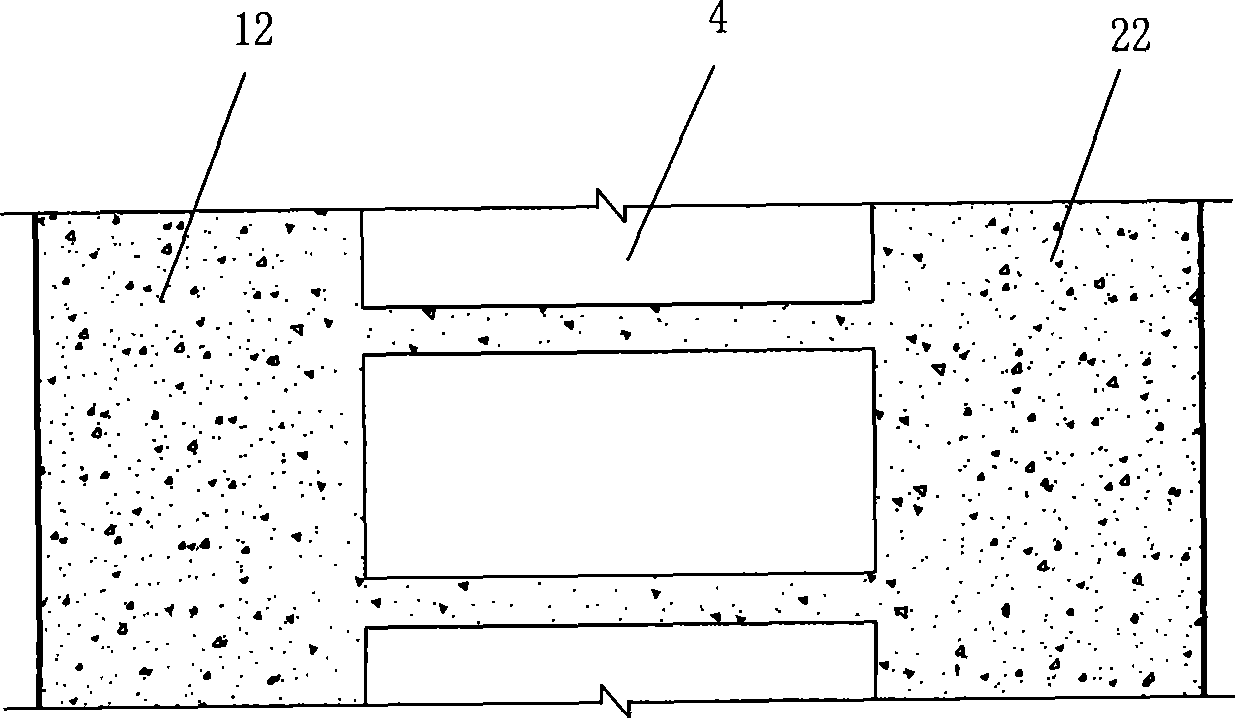

[0027] figure 1 It is a schematic diagram of the cross-sectional structure of the mid-span section of the present invention, figure 2 for figure 1 Enlarged view at I, image 3 for figure 1 Along the schematic diagram of A, Figure 4 It is a schematic diagram of the cross-sectional structure of the arch foot section of the present invention, Figure 5 for Figure 4 Schematic diagram along direction B, Figure 6 It is a schematic diagram of the arch structure of the present invention. The steel box-concrete composite box-slab arch structure of the present embodiment includes steel box arch I 1 and steel box arch II 2 arranged in parallel, the bottom plate of steel box arch I 1 and steel box arch II 2 The bottom prefabricated slabs 3 are arranged vertically side by side between the bottom plates of the steel box arch I1 and the top plate of the steel box arch II 2. The bottom plates of 2 respectively extend laterally to the inside, and the two ends of the bottom prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com