Clutch actuating mechanism of automatic mechanical speed variator

A technology for automatic transmissions and actuators, applied in the direction of non-mechanical drive clutches, electric clutches, fluid drive clutches, etc., can solve the problems of complex transmission methods, complex parts, and difficult processing, and achieve stable transmission, high precision, The effect of accelerating the separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

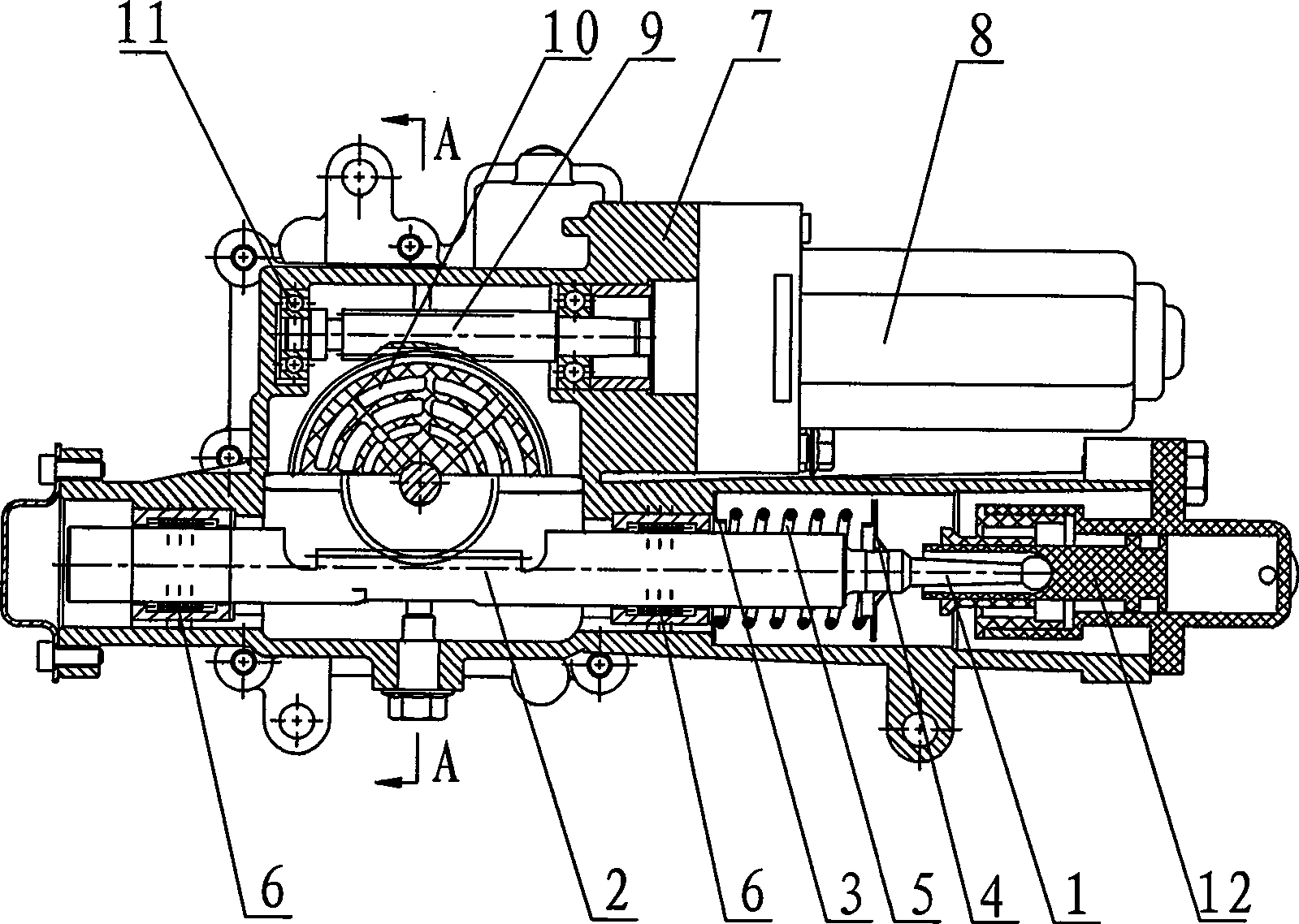

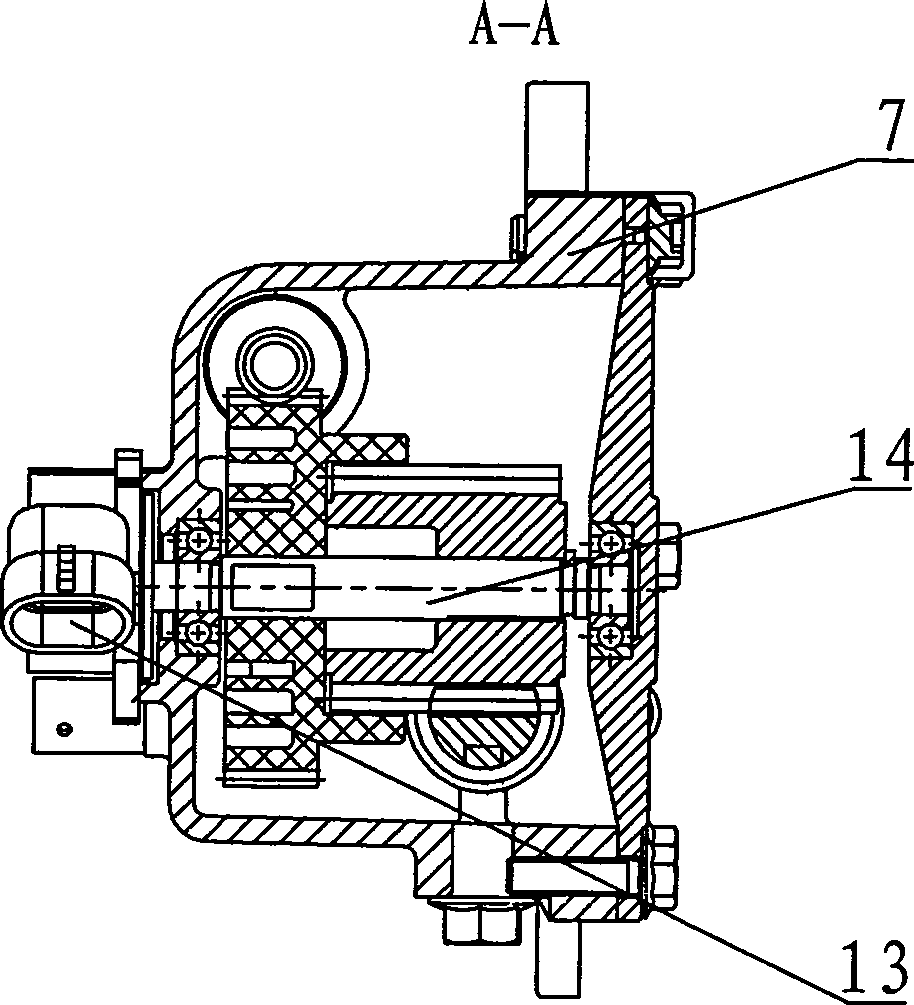

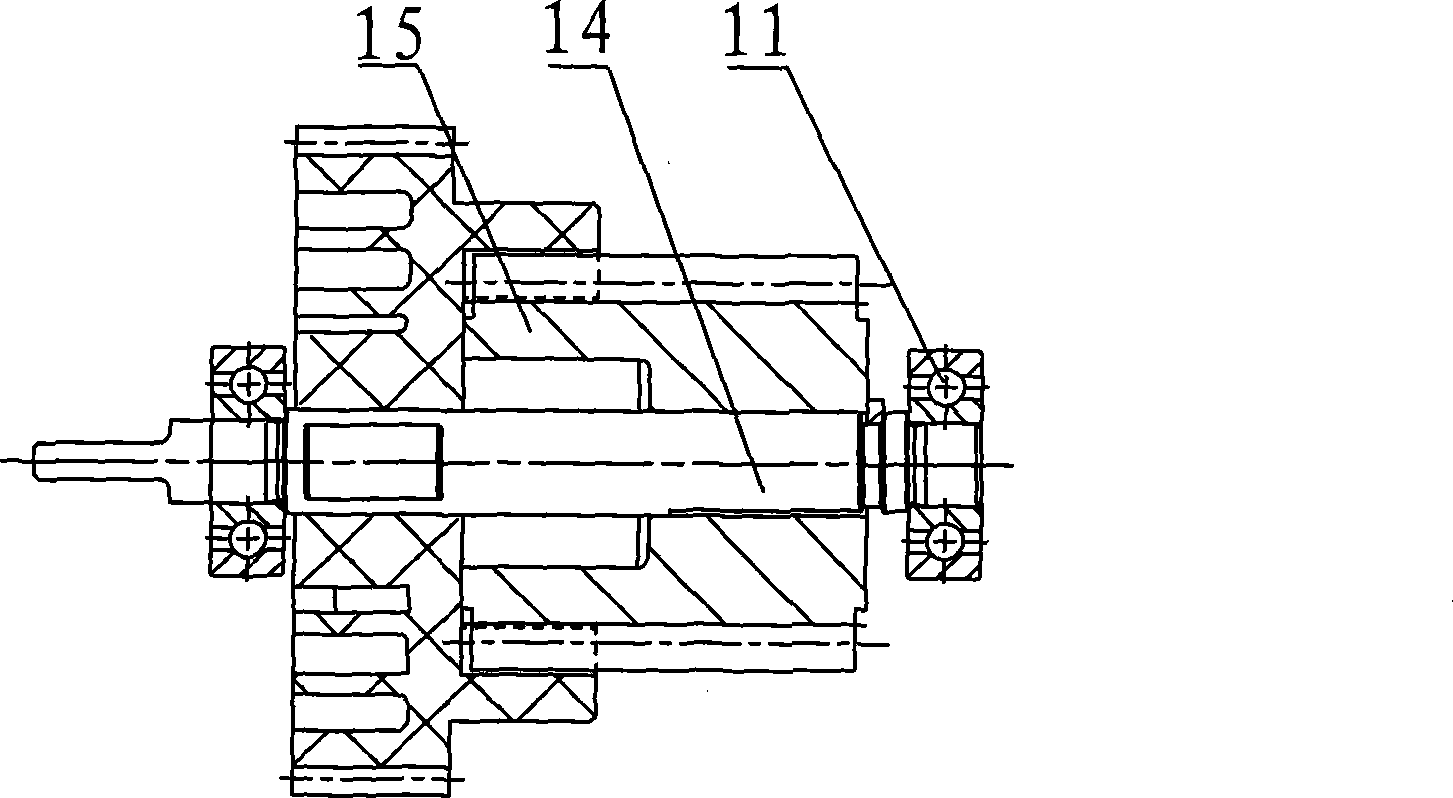

[0020] Example 1, such as figure 1 , 2 . As shown in 3, a mechanical automatic transmission clutch actuator includes a clutch driving device and a clutch master cylinder assembly. The clutch driving device includes a clutch motor 8, a clutch motor worm 9, a clutch motor worm wheel 10 and a clutch The clutch gear 15 engaged by the motor worm gear 10; the clutch master cylinder assembly includes a master cylinder piston 12, which is characterized in that a clutch rack assembly is arranged in the clutch housing 7, and the clutch driving device passes through the clutch rack assembly Connect with the clutch master cylinder assembly.

[0021] The clutch rack assembly includes a clutch rack 2 with a clutch rack push rod 1, a spring guide sleeve 3, a clutch rack block 4 and a clutch master cylinder preload spring 5. The clutch rack push rod 1 Connected with the clutch master cylinder assembly, the clutch rack 2 is set in the clutch housing 7 through a linear bearing 6, the spring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com