Method and apparatus to control off-going clutch torque during torque phase

A clutch and torque technology, applied in the field of control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

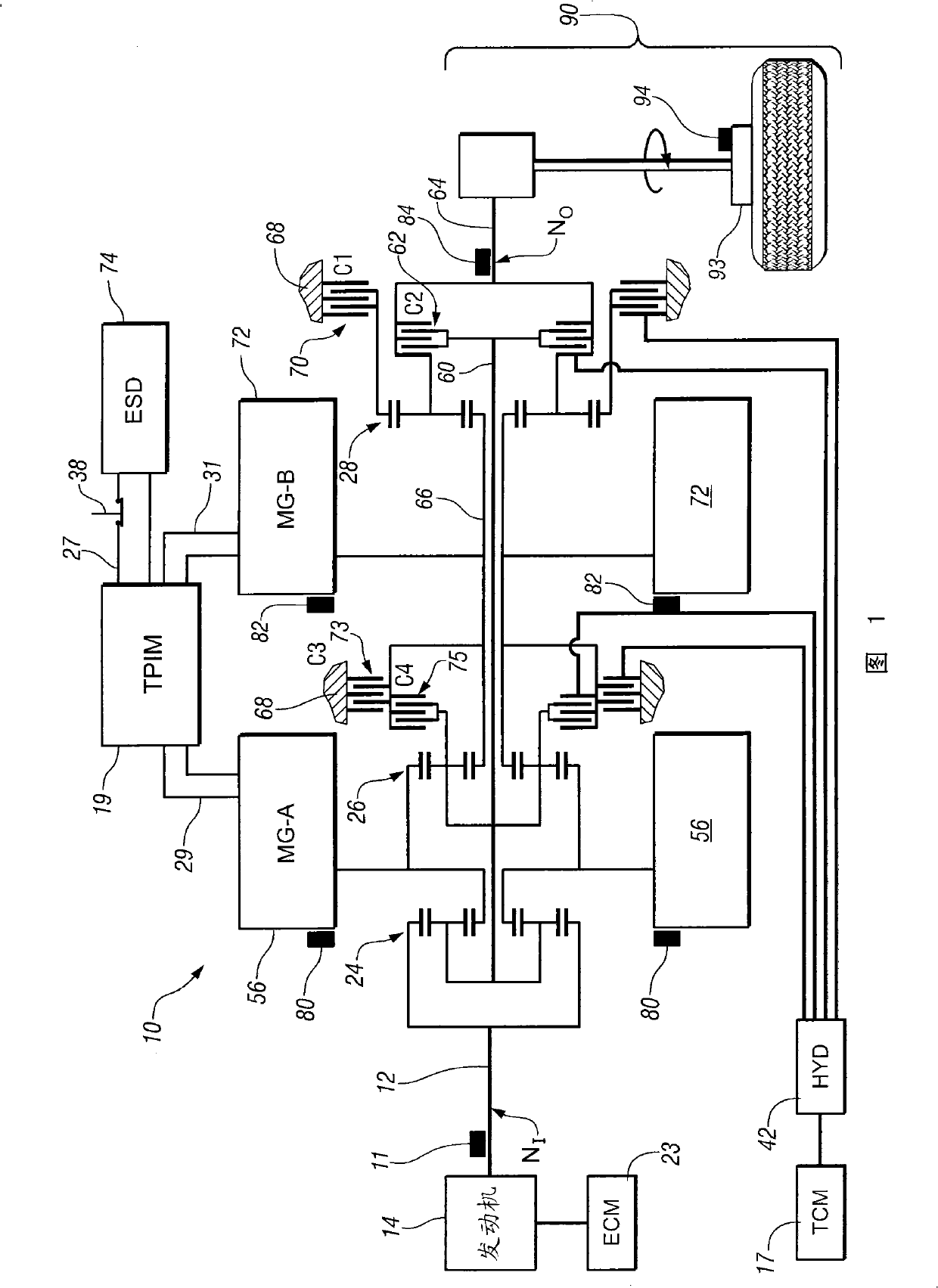

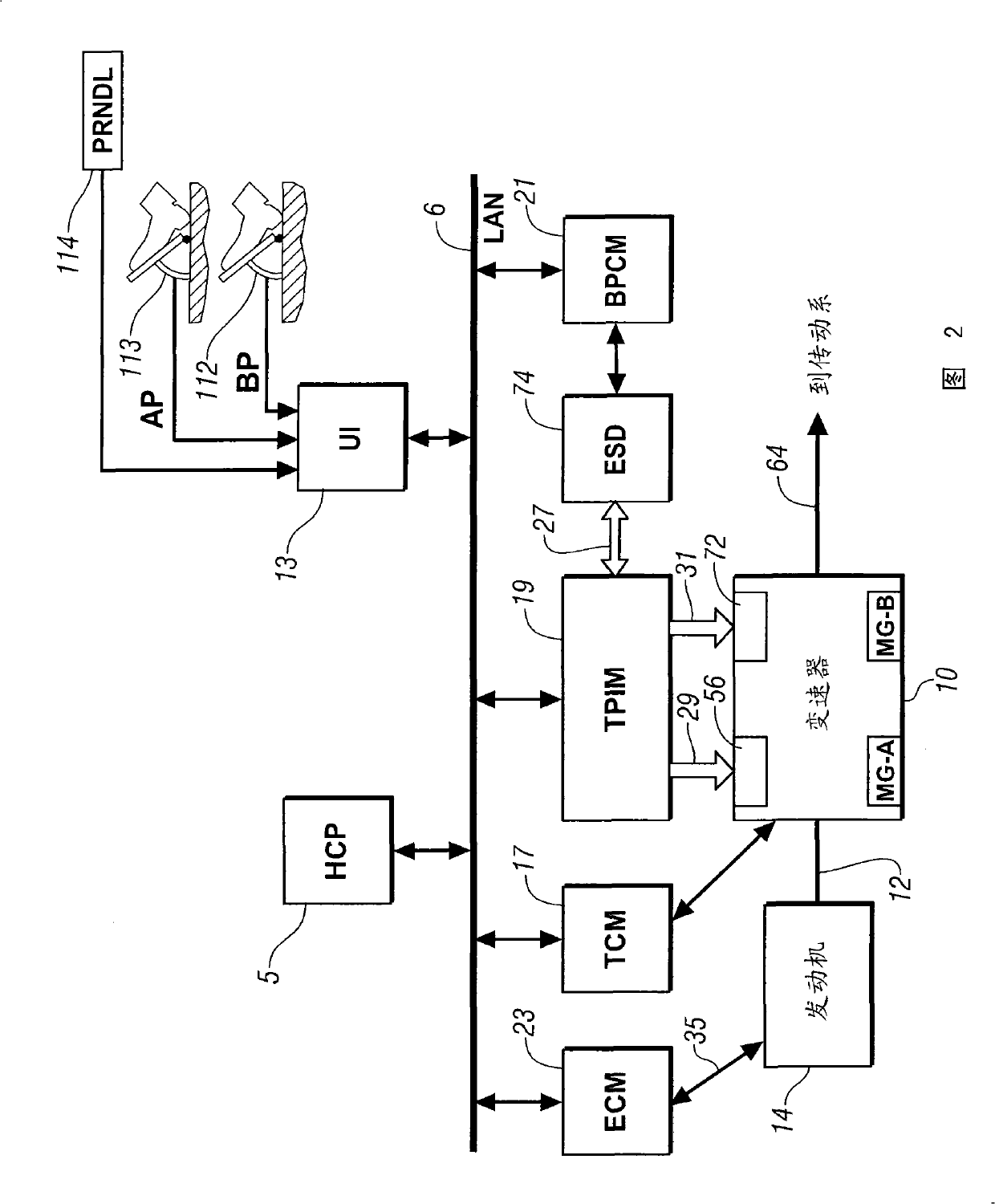

[0020] Reference is now made to the drawings, in which the drawings are for purposes of illustrating certain exemplary embodiments only and are not intended to be limiting thereof. figure 1 and 2 An exemplary electromechanical hybrid powertrain is depicted. figure 1 Depicted is an exemplary electromechanical hybrid powertrain according to the present disclosure comprising a two-mode compound split electromechanical hybrid transmission 10 operatively connected to an engine 14 and a first electric machine ('MG-A') 56 and a second motor ('MG-B') 72 . The engine 14 and the first electric machine 56 and the second electric machine 72 each generate power transmittable to the transmission 10 . The power generated by the engine 14 and the first and second electric machines 56 and 72 and transmitted to the transmission 10 is based on the power, respectively referred to herein as T I , T A and T B The input torque and are referred to in this paper as N I , N A and N B explained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com