powerplant

A technology for power plant and generating device, applied in power plant, electric power plant, transmission and other directions, can solve the problems of internal combustion engine consumption, large drag loss, large-scale device and reduced mountability, etc., to reduce losses and improve mountability. , the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

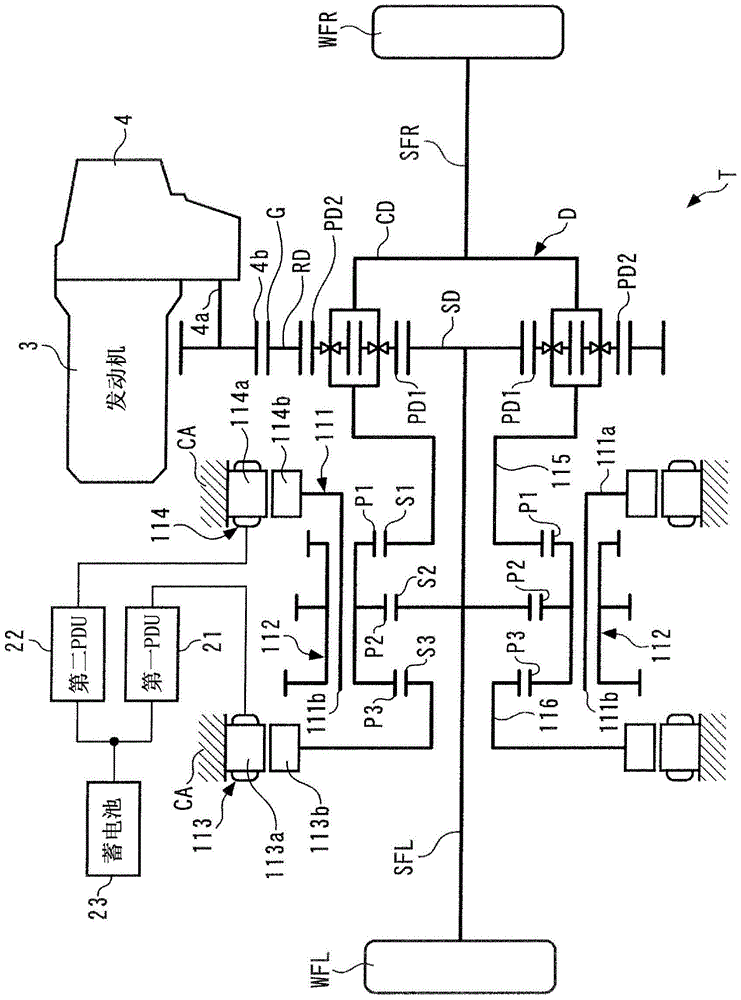

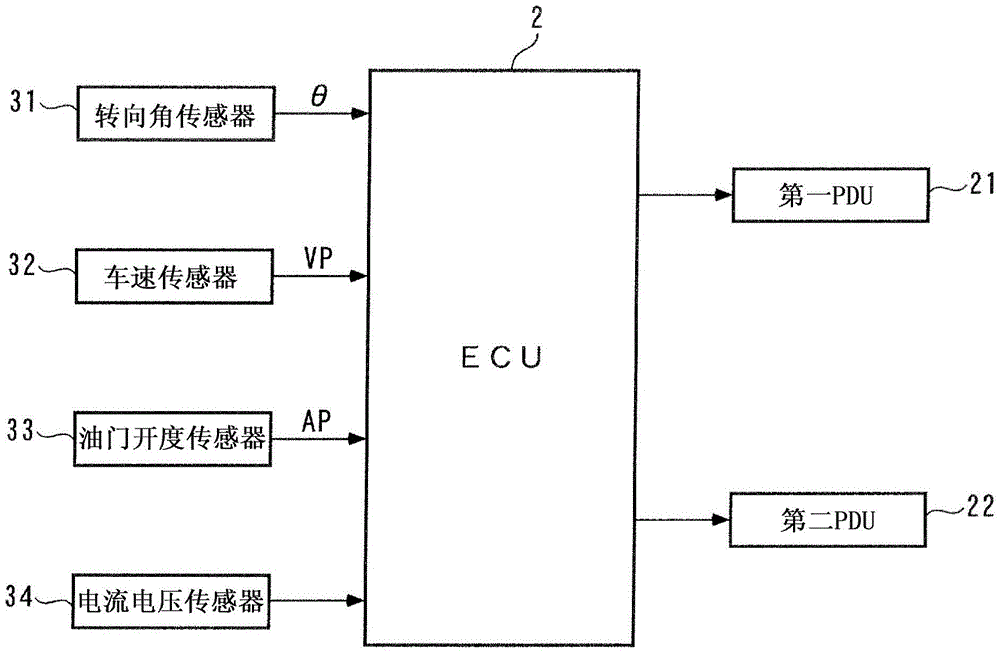

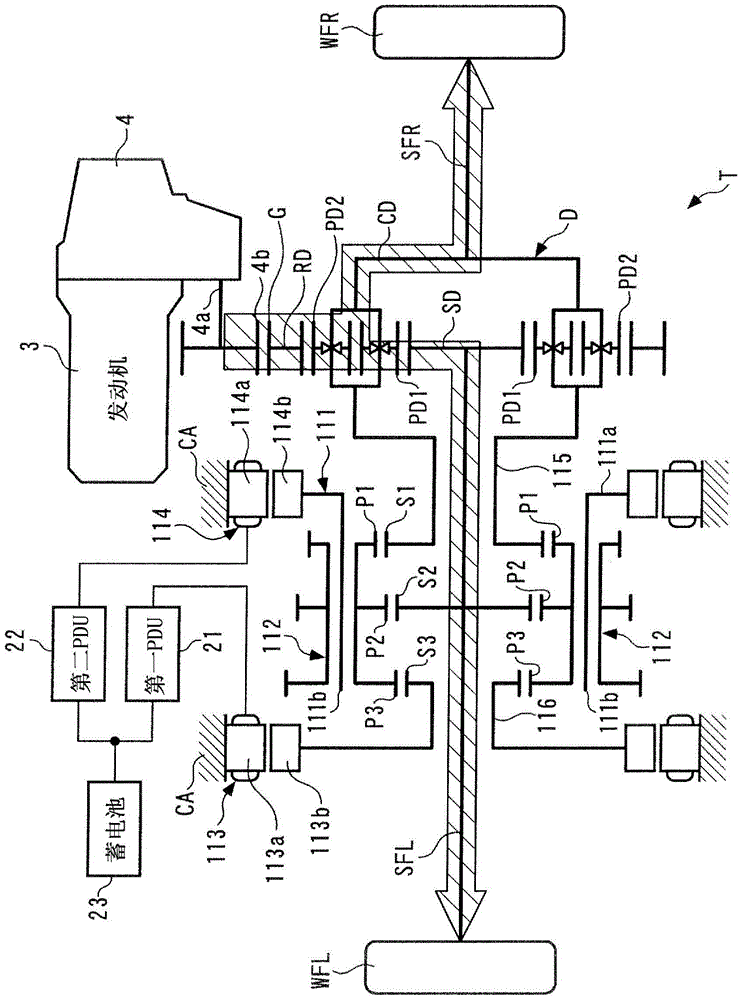

[0074] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The illustrated internal combustion engine (hereinafter referred to as "engine") 3 is mounted on a FF (Front Engine-Front Drive) type four-wheeled vehicle (not shown). The power transmission device T according to the first embodiment of the present invention is connected to the engine 3 via the transmission 4, and transmits the torque of the engine 3 (hereinafter referred to as "engine torque") to the left front wheel WFL and the right front wheel WFR of the vehicle. .

[0075] The power transmission device T includes a differential device D, a carrier member 111 , a triple pinion 112 , a first electric motor 113 , and a second electric motor 114 . The aforementioned differential device D, the carrier member 111 , the first electric motor 113 , and the second electric motor 114 are arranged coaxially with each other. The differential device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com